A heart simulation structure, its forming method and special mold

A heart and mold technology, which is applied in the field of heart simulation structure and its forming method and special mold, can solve the problems of artificial heart physiological function matching, and achieve the effects of saving time and capital costs, high biocompatibility, and expanding the usable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

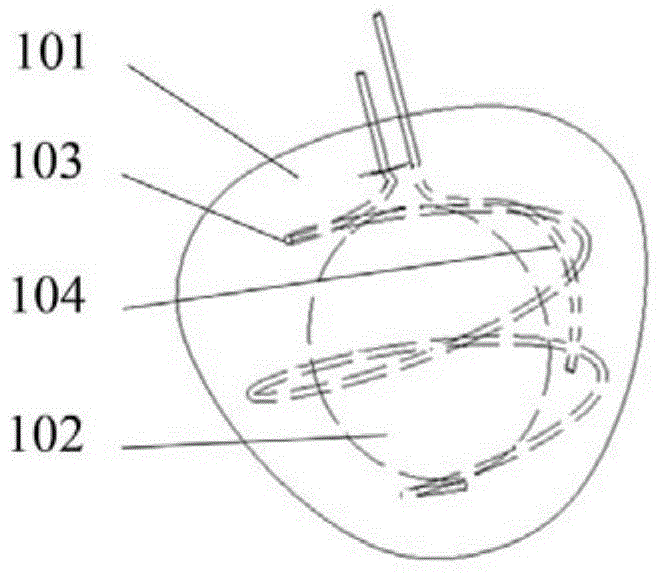

[0047] Example 1 A method for preparing a heart simulation structure containing a ventricle and an atrium by using the combined mold method

[0048] 1) Prepare a special mold: Utilize the method of three-dimensional punching to prepare the shell top and shell bottom of a special mold containing a ventricle and an atrium (total two heart structural chambers) heart simulation structure. The material used is ABS plastic, and it is polished and profiled. Ensure that the top of the shell and the bottom of the shell can be molded together;

[0049] 2) Prepare the vascular system: mix part of the prepared sodium alginate with a mass percentage concentration of 2% and vascular endothelial cells so that the cell density is 10 6 pcs / mL; the vascular system catheter with polyurethane inner layer and sodium alginate hydrogel containing vascular endothelial cells was prepared by double nozzle 3D printing method, and CaCl with a mass fraction of 2% was used 2 Cross-linking and fixing sodiu...

Embodiment 2

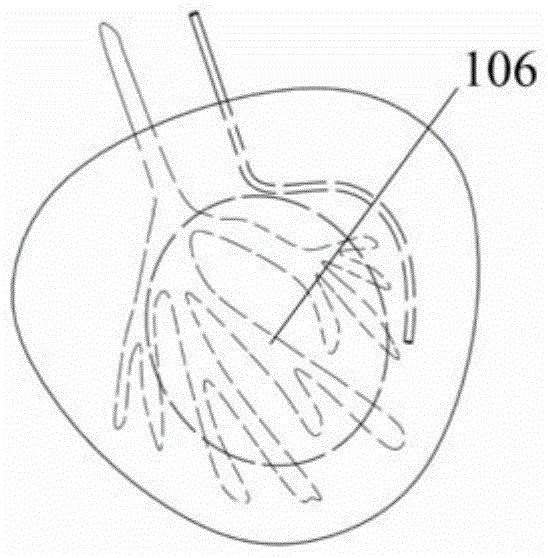

[0054] Example 2 A method of preparing a heart simulation structure containing a single ventricle by using the combined mold method

[0055] 1) Preparing a special mold: using machining to prepare the shell top and shell bottom of a special mold containing a single-ventricular heart simulation structure, the material used is plexiglass, and polished to ensure that the shell top and shell bottom can be molded;

[0056] 2) Prepare the vascular system: mix part of the prepared sodium alginate with a mass percentage concentration of 4% and vascular smooth muscle cells, so that the cell density is 10 4 pieces / mL; the vascular system catheter with polycaprolactone as the inner layer and sodium alginate hydrogel containing vascular smooth muscle cells as the outer layer was prepared by double-nozzle 3D printing method, and CaCl with a mass fraction of 1% was used 2 Cross-linking and fixing sodium alginate to obtain a dendritic vascular system;

[0057] 3) Prepare the nervous system:...

Embodiment 3

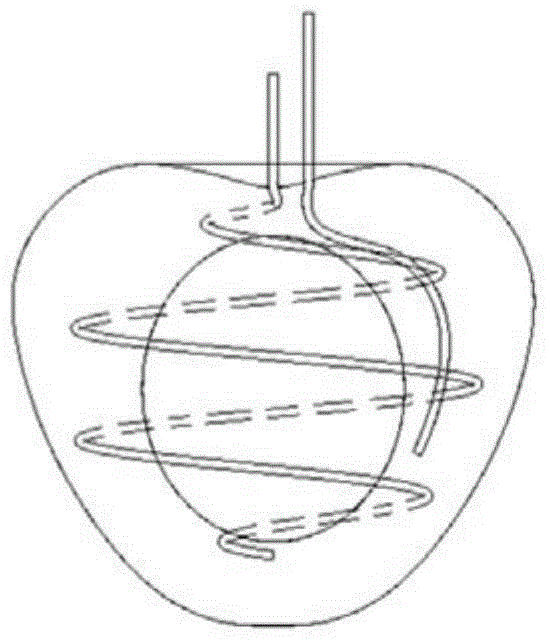

[0062] Example 3 A method for preparing a simulated heart structure containing two ventricles and two atria by using the combined mold method

[0063] 1) Prepare a special mold: Utilize the method of three-dimensional punching to prepare the shell top and shell bottom of the special mold containing the heart simulation structure of two ventricles and two atria (four heart chamber structures). The material used is stainless steel, and it is polished and profiled to ensure Housing top and housing bottom can be molded together;

[0064] 2) Prepare the vascular system: Mix a portion of the prepared gelatin with a mass percentage concentration of 20% and 1% fibrinogen in equal volumes, and add a mixture of adipose-derived stem cells / vascular endothelial cells (1:1) to make the cell density 10 6 pieces / mL; the vascular system catheter with the inner layer of polyurethane and the outer layer of dendritic vascular system with adipose-derived stem cells / vascular endothelial cell gelati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com