High Voltage Electrolyte for Li-ion Batteries

A lithium-ion battery and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve problems such as difficult formation, two-phase separation, and reduced oxidation resistance of mixed electrolytes, achieving high safety and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

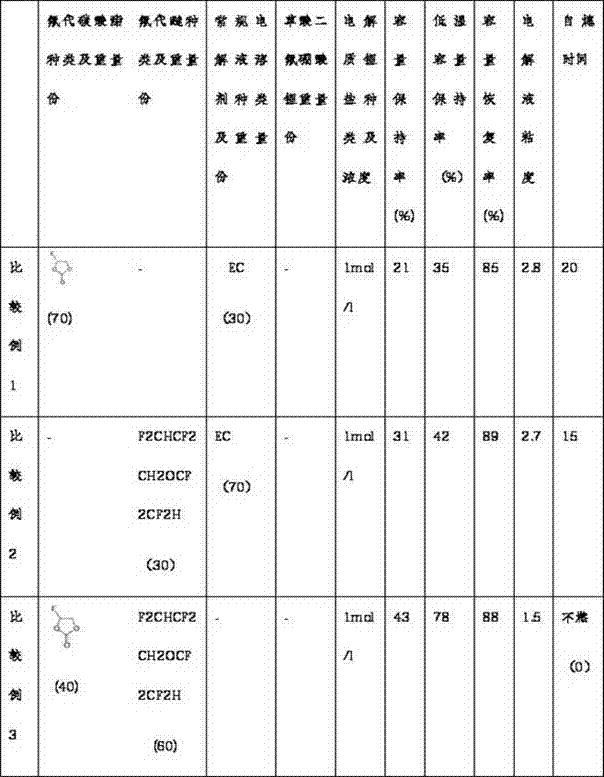

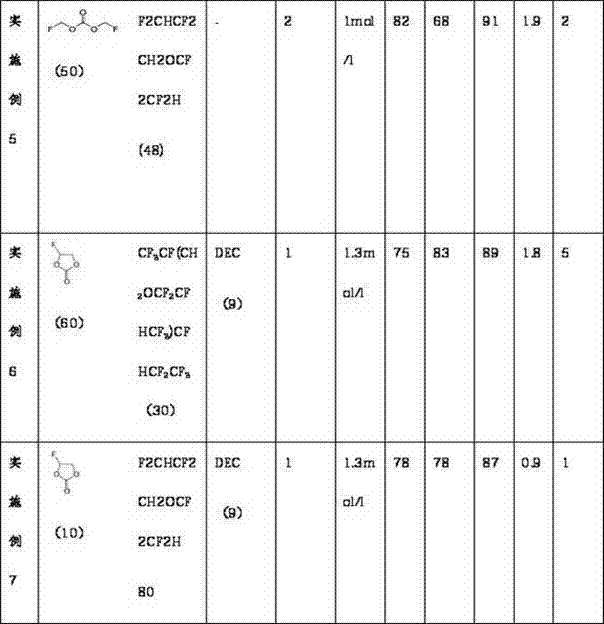

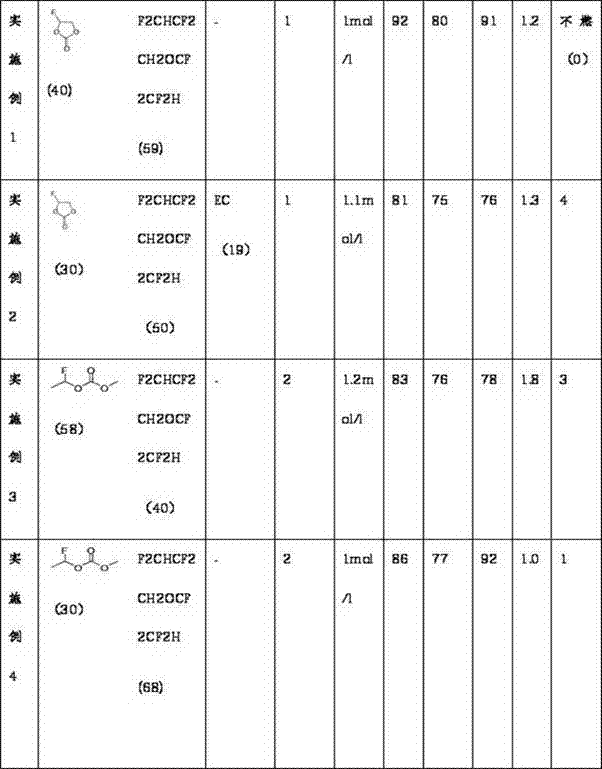

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described below, but should not be limited to the following embodiments:

[0039] Provide a kind of high-voltage electrolytic solution for lithium ion battery, the preparation process of described battery positive pole and negative pole and electrolytic solution:

[0040] 【Preparation of positive electrode】

[0041] The positive electrode is prepared through the following steps: 90% by weight of lithium nickel manganese oxide, 5% by weight of polyvinylidene fluoride (PVdF), and 5% by weight of acetylene black are mixed; N-methylpyrrolidone is added to form a slurry; the slurry The material was coated on both surfaces of the aluminum current collector and then dried.

[0042] 【Preparation of Negative Electrode】

[0043] The negative electrode was prepared by the following steps: 90% by weight of graphite powder and 10% by weight of CMC+SBR were mixed to form a slurry; the slurry was coated on one surface of a copper current coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com