0.9-mu m laser device for double-end polarization pump

A pump light and laser technology, applied in the laser field in the field of laser technology, can solve the problems of low doping concentration of laser crystal, poor pump absorption, low optical efficiency, etc., so as to improve optical efficiency and internal efficiency. , Improve the effect of pump absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

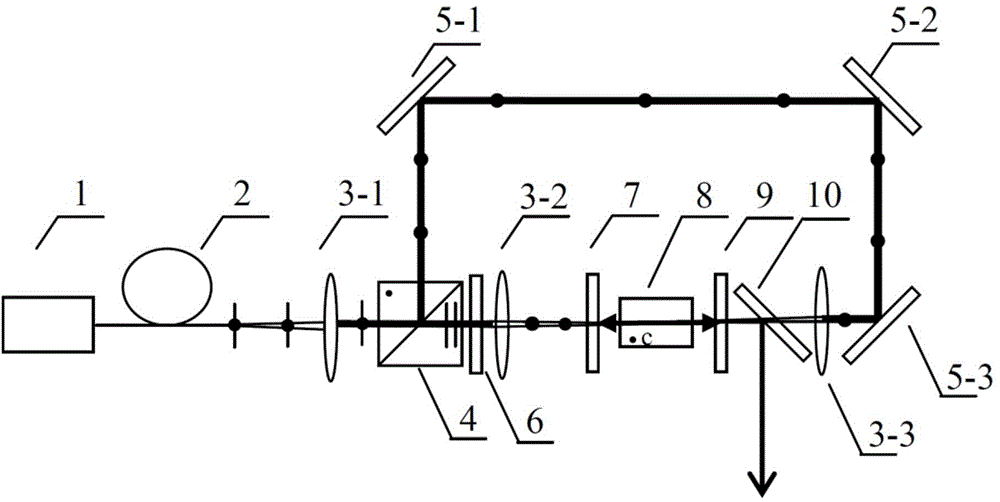

[0025] A double-ended polarization-pumped 0.9 μm laser, see figure 1 , including: 808nm laser diode pump source 1, energy transmission fiber 2, coupling lens 3 (including: first coupling lens 3-1, second coupling lens 3-2 and third coupling lens 3-3), polarization beam splitter prism 4. Pump light reflector 5 (comprising: first pump light reflector 5-1, second pump light reflector 5-2 and third pump light reflector 5-3), half-wave plate 6, Laser reflector 7, laser crystal 8, laser output mirror 9 and beam splitter 10.

[0026] Among them, the coupling lens 3, the polarization beam splitter prism 4, and the half-wave plate 6 are coated with pump light antireflection film, the pump light reflector 5 is coated with pump light high reflective film, and the laser reflector 7 and the beam splitter 10 are average Mirror, coated with pump light high-transparency, laser high-reflection film system, laser crystal 8 is neodymium-doped yttrium vanadate (Nd:YVO 4 ) crystal, coated with p...

Embodiment 2

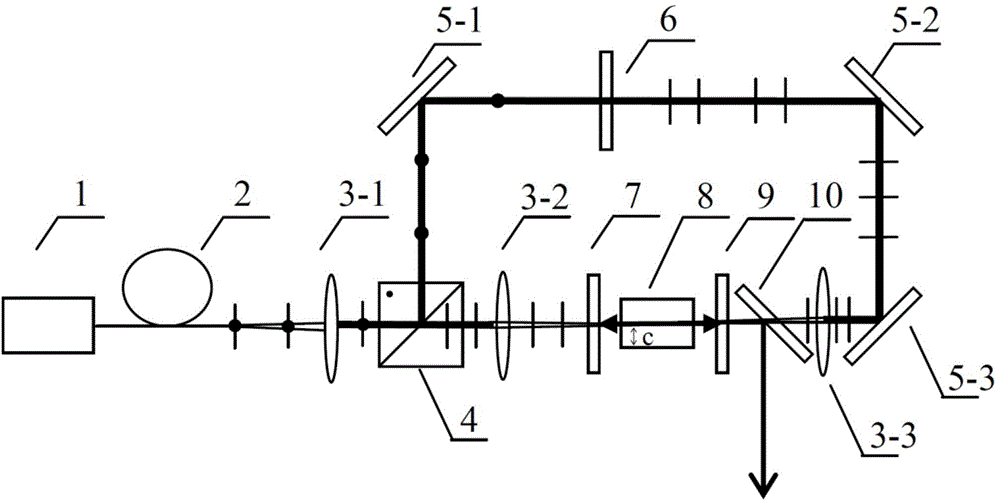

[0036] A double-ended polarization-pumped 0.9 μm laser, see figure 2 , the difference from Embodiment 1 is that the placement direction of the laser crystal 8 is placed horizontally on the c-axis, so the horizontally polarized pump light emitted by the polarization beam splitter prism 4 is π-polarized relative to the laser crystal 8, and is focused by the second coupling lens 3-2 After entering the laser crystal 8; the half-wave plate 6 is arranged on the optical path of the vertically polarized pump light reflected by the polarization splitter prism 4, and its polarization direction is changed to horizontal polarization to realize double-ended π-polarized pumping of the laser crystal 8.

[0037] The rest of the operation process is the same as that of Embodiment 1, and will not be repeated here in this embodiment. During specific implementation, the implementation mode provided in Embodiment 1 or Embodiment 2 can be selected according to the requirements on the polarization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com