Growth factor-loading silk fibroin/collagen bracket material and preparation method thereof

A growth factor and collagen technology, applied in the field of silk fibroin/collagen scaffold material and its preparation, can solve the problems of losing biological activity and failing to reach the effective concentration, so as to prolong the functional effect and solve the half-life in vivo Too short, prolonged for full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

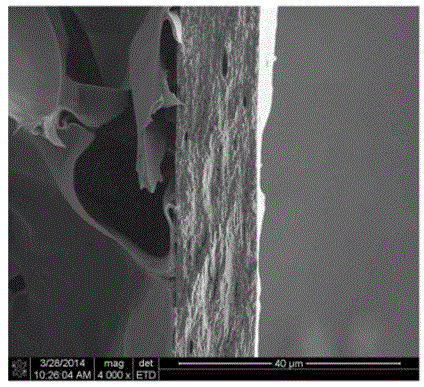

[0025] Example 1: Preparation of loose layer silk fibroin / collagen film and dense layer silk fibroin / collagen film

[0026] 1. Preparation of silk fibroin

[0027] Cut silkworm cocoons into pieces and add 0.5% Na 2 CO 3 solution, in a constant temperature water bath at 98±2°C for 30 min, twice in total. After taking it out, wash it twice with boiling water, and then wash it 8 times with deionized water. Dry in an oven at 60° C. to obtain dry silk fibroin (ie, silk fibroin). Weigh the silk fibroin silk after silk degumming, use CaCl 2 / H 2 O / C 2 h 5 OH solution (molar ratio 1:8:2) was dissolved in a constant temperature water bath at (78±2)°C, and the bath ratio was 1:25. Filter with gauze to obtain the silk fibroin stock solution. Dialyze with a fibrous semipermeable membrane dialysis bag with a molecular weight cut-off of 8000 D-14000 D for 3 days to remove calcium chloride and ethanol. Filter to obtain silk fibroin solution.

[0028] 2. Collagen preparation

[...

Embodiment 2

[0035] Example 2: Preparation of TGF-β1 Nanoparticles Encapsulated

[0036] Polylysine is dissolved in deionized water with pH=7.4, the content is 1 mg.ml -1 . Dissolve TGF-β1 in 0.2 ML water, add 5 mL, 1 mg.ml -1 The sodium heparin solution was mixed overnight. Add TGF-β1-heparin sodium solution to 2 mL, 1 mg.ml -1 In the PLL solution, shake on a vortex mixer for 15 s, and then incubate at room temperature for 30 min. TGF-β1-PLL-heparin sodium nanoparticles can be obtained.

Embodiment 3

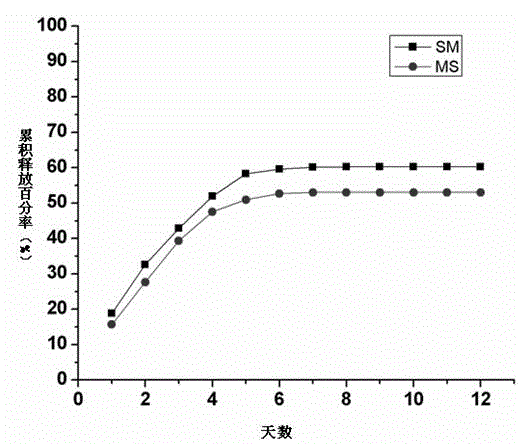

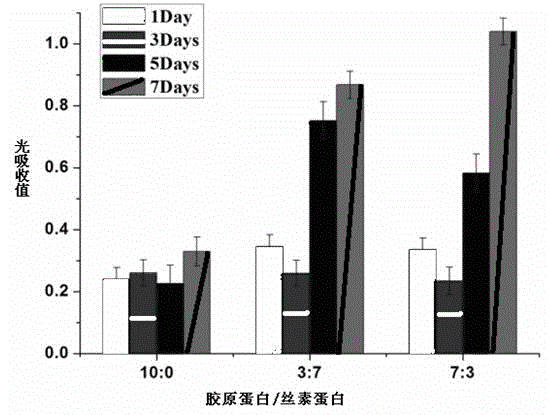

[0037] Example 3: Preparation of silk fibroin / collagen scaffold material loaded with TGF-β1

[0038] The cross-linked loose layer silk fibroin / collagen membrane prepared in Example 1 was wetted with double-distilled water and spread flat, and the PLL-heparin nanoparticle solution loaded with TGF-β1 prepared in Example 2 was added dropwise on the surface, 4- Air-dry at 8°C until there is no flowing liquid on the surface, then wet the cross-linked dense layer silk fibroin / collagen membrane and spread it on the upper surface of the cross-linked loose layer silk fibroin / collagen membrane, and air-dry at 4-8°C to obtain TGF-β1 silk fibroin / collagen scaffold material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com