Improved A/O (anaerobic/aerobiotic) technique for treating acrylonitrile wastewater

A process and raw water technology, applied in the process field of improving A/O treatment of acrylonitrile wastewater, can solve the problems of refractory microorganism utilization, inability to be effectively removed, acrylonitrile wastewater COD discharge not up to standard, etc., to save engineering investment and operation cost, stable operation, and the effect of reducing pool capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A specific example of an improved A / O process for treating acrylonitrile wastewater according to the present invention is described below. Examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited with the following examples.

[0012] The present invention will be described below in conjunction with the drawings and specific embodiments.

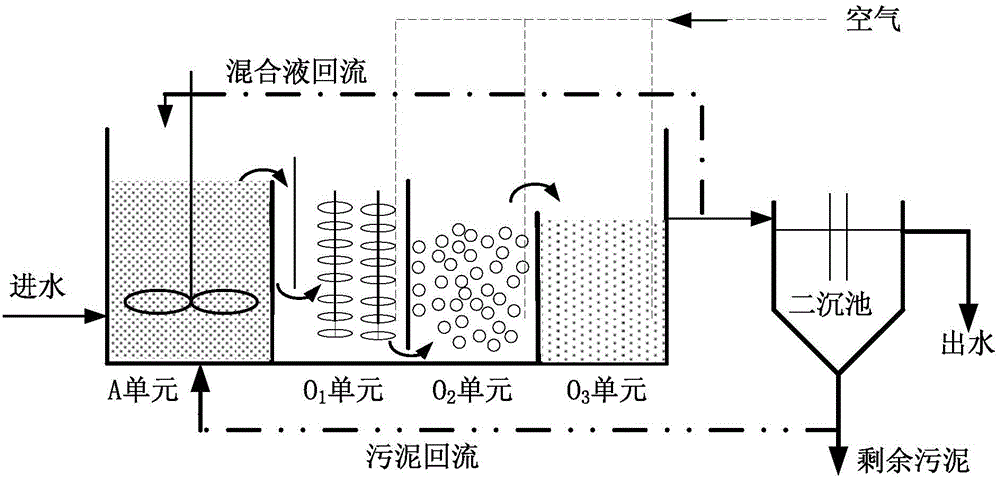

[0013] see figure 1 , figure 1 For this example, an improved A / O process for treating acrylonitrile wastewater includes anoxic pool and aerobic pool. The aerobic pool is divided into three sections, and the process flow is anoxic denitrification pool-biological contact oxidation pool-suspended biofilm Pool—activated sludge pool. The raw water enters from the bottom of the anoxic pond, and the raw water flows into the O in the aerobic pond by itself after the anoxic reaction. 1 District, in O 1 A baffle is set at the water inlet, so that the water inlet is from O 1 Enter the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com