Porous alumina ceramic, and preparation method and application thereof

A technology of porous alumina and phase alumina, which is applied in the field of porous ceramic materials, can solve the problems of difficult regulation of porosity and pore size distribution, complicated preparation process, unsuitable for fine particle filtration and gas-liquid phase separation, etc., and achieves good application prospects. , the effect of good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

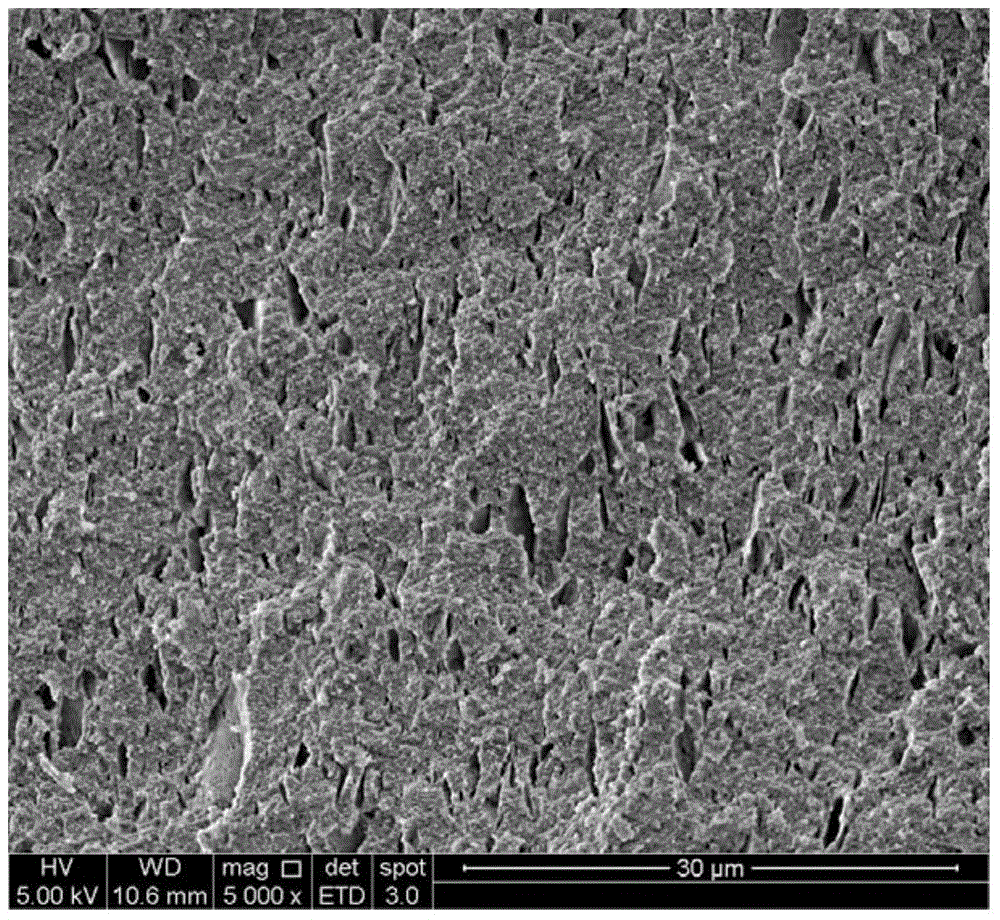

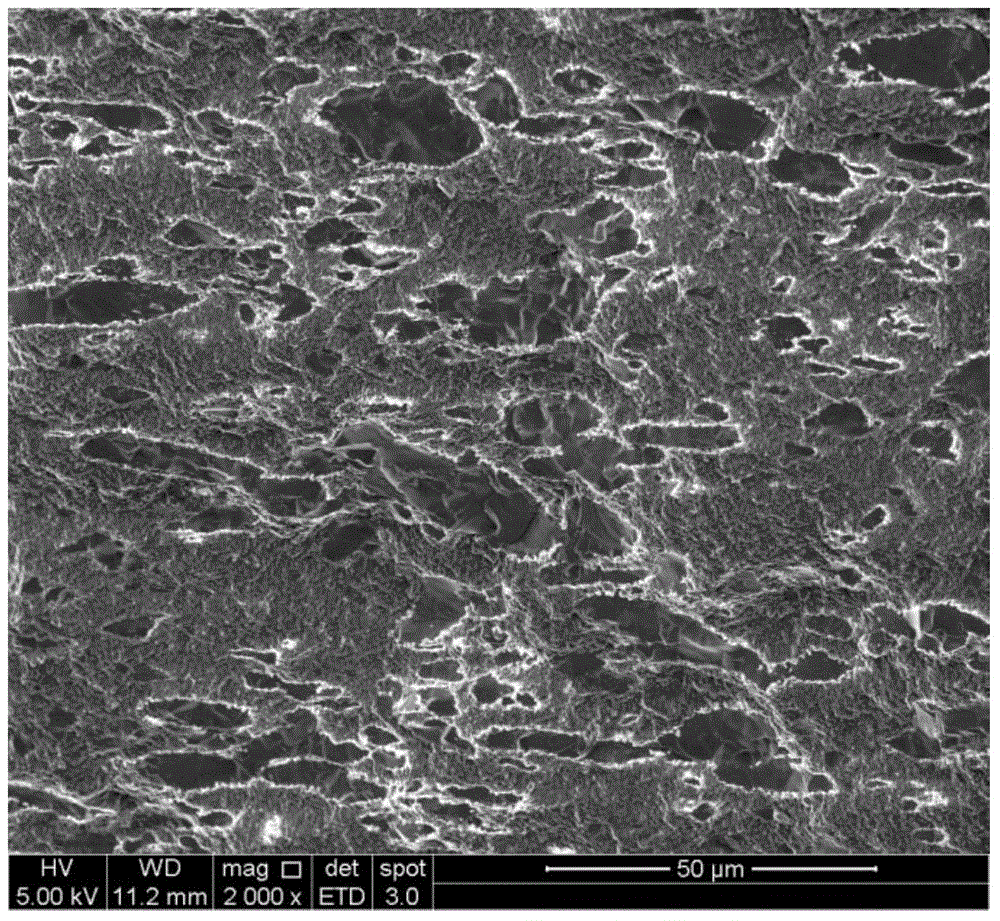

[0036] In this embodiment, the structure of the porous alumina ceramic material is: α-phase alumina is used as the matrix, and a plurality of pores connected in three dimensions are distributed in it, and the pore diameter is distributed in a dual mode, that is, the plurality of pores are divided into two types according to their pore diameters. , one is small pores with a pore diameter of 60nm to 150nm, and the other is a large pore with a pore diameter of 2um to 5um; in terms of volume percentage, in the porous alumina ceramic material, the volume of large pores accounts for 10%, and the volume of small pores Accounted for 41%.

[0037] The preparation method of above-mentioned porous alumina ceramic material is as follows:

[0038](1) The γ-phase alumina powder with a particle size of 10nm to 100nm is used as the matrix powder, and activated carbon powder with a particle size of 2um to 5um is added as a pore-forming agent powder. The volume ratio of the pore-forming agent p...

Embodiment 2-7

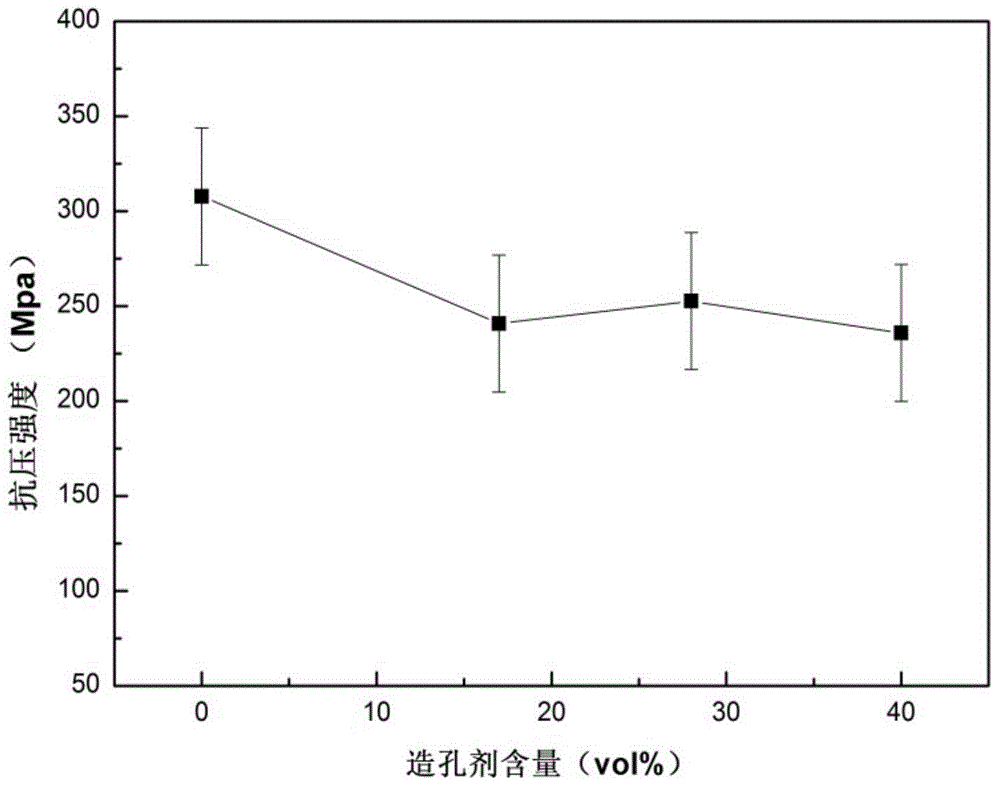

[0044] In Examples 2-7, the structure of the porous alumina ceramic material is basically the same as that of Example 1, except that the volume percentage of macropores is shown in Table 1 below.

[0045] The preparation method of the porous alumina ceramic material is basically the same as that in Example 1, except that the volume content of the pore-forming agent powder and the sintering temperature are shown in the table below. That is, by adjusting the volume content of the pore-forming agent and the sintering temperature, the ratio of large pores to small pores in the bimodal porous alumina ceramic material can be adjusted, thereby preparing porous ceramics with different porosity.

Embodiment 8-9

[0047] In Examples 8-9, the structure of the porous alumina ceramic material is: α-phase alumina is used as the matrix, and a plurality of pores connected in three dimensions are distributed therein. 60nm to 150nm; in terms of volume percentage, the pores in the porous alumina ceramic material respectively account for 50% and 36% of the total volume.

[0048] The preparation method of this porous alumina ceramic material is basically the same as the preparation method in Example 1, the difference is that no pore-forming agent powder is added to the matrix powder, so when the sintered bulk material is mechanically processed into the desired shape No porogen removal process is required. For specific process parameters, please refer to Table 1 below.

[0049] Table 1: Process parameters for preparing porous alumina ceramic materials in Examples 1-9

[0050] Example

[0051] 2

[0052] The porous alumina ceramic material obtained in the above-mentioned exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com