Porous biomass acidic solid material, and preparation and application thereof

A technology of acidic solids and biomass, which is applied in the preparation of carboxylic acid esters, organic compounds, lignin derivatives, etc. It can solve the problems of limited application range, low material specific surface area, complex process, etc., and achieve rich sources of raw materials , simple preparation process and high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

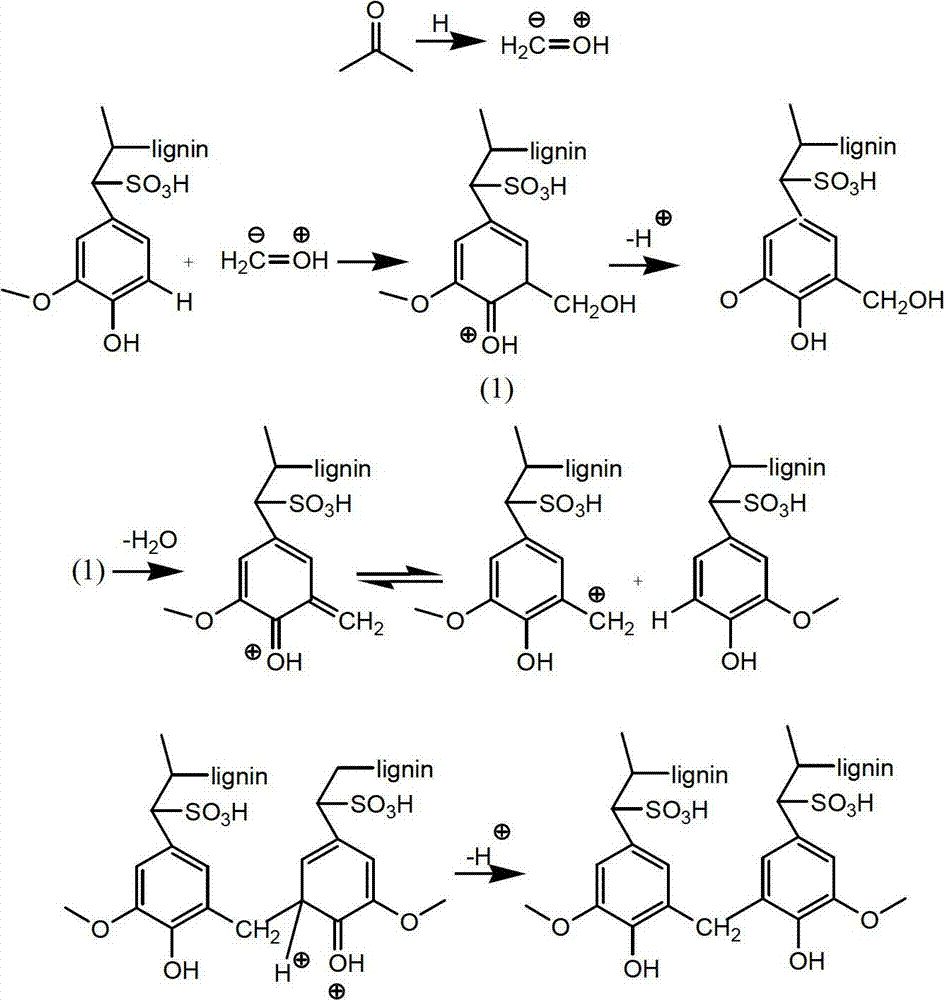

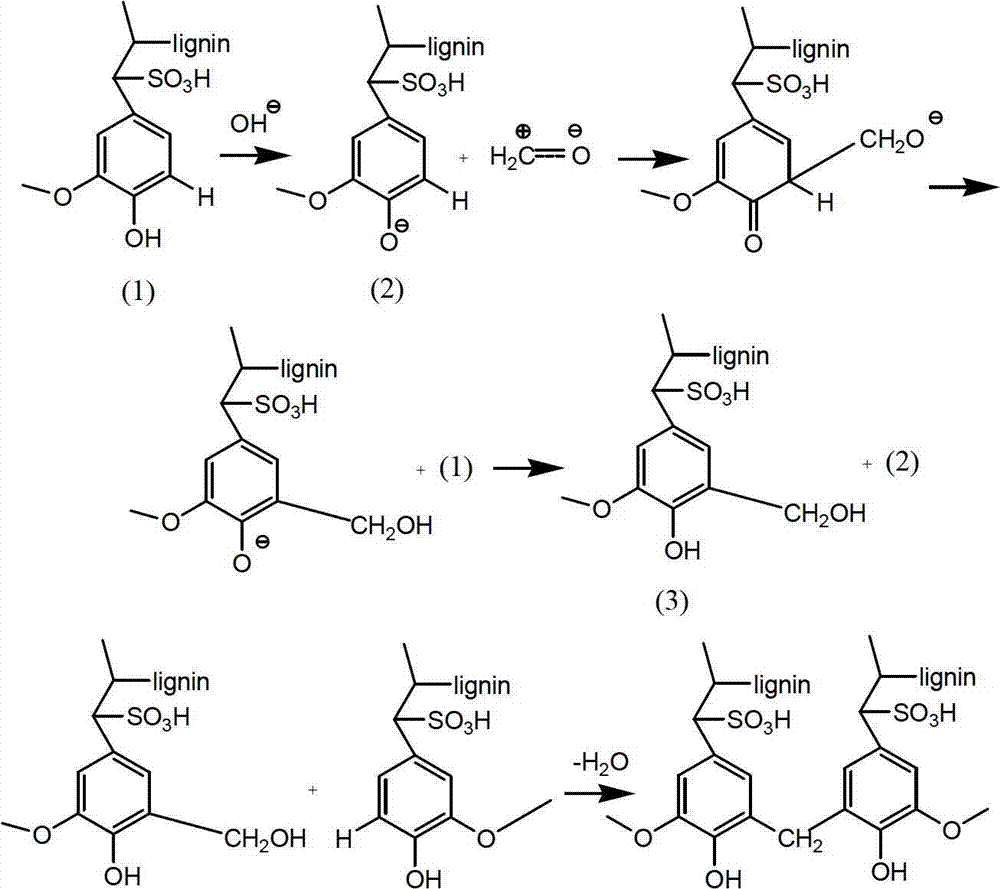

Method used

Image

Examples

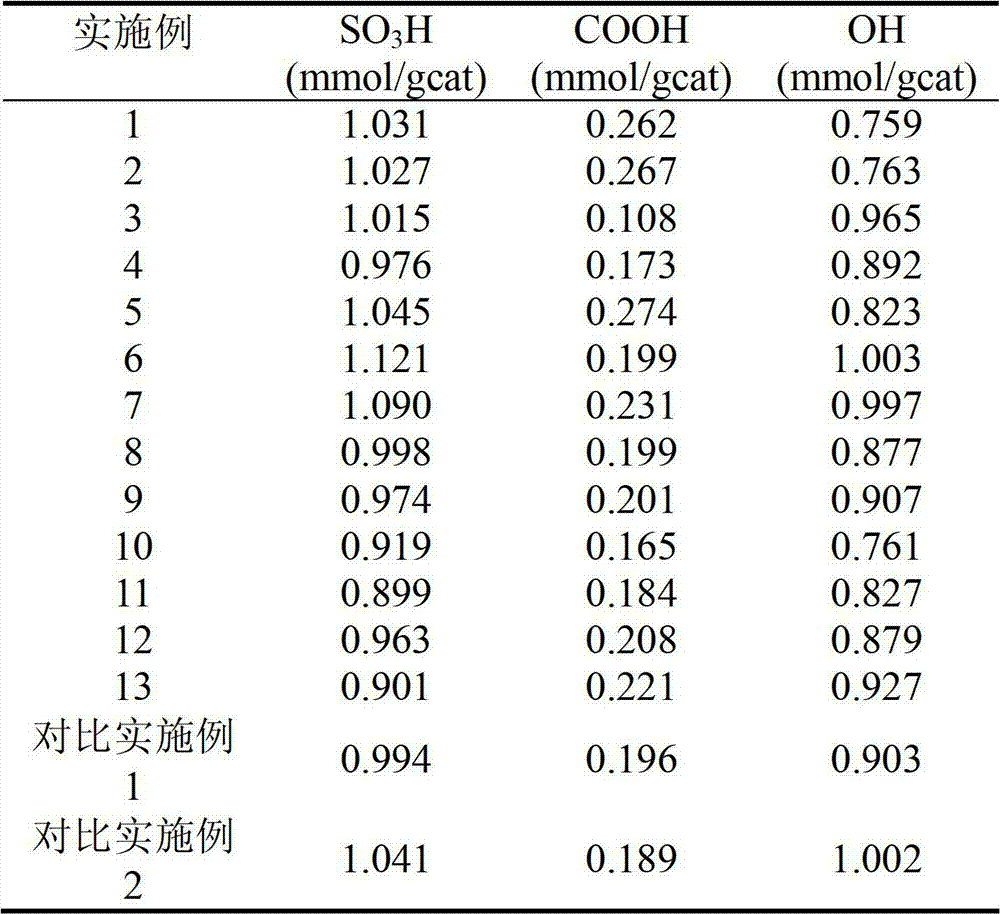

Embodiment 1

[0030] Weigh 100g of magnesium lignosulfonate, make it into an aqueous solution with a mass concentration of 30%, add 75g of a mass fraction of 37% formaldehyde solution into a pressure-resistant polyester bottle, add 10g of SBA-15 as a template, mix, stir, and add to the reaction Mass fraction is 35g of hydrochloric acid of 37% in container, stirs until solution mixes, airtight, is placed in 100 ℃ of ovens and reacts 24h. Then dry the prepared black material at 110 ° C, grind, dry, grind, treat with hydrofluoric acid at room temperature for more than 12 hours to remove the template, and treat with 1M sulfuric acid for 2 hours to ensure that the magnesium ions are completely exchanged, and wash to no sulfate Ions, drying, that is, porous biomass acidic material. Neutralization titration, the acid content that obtains this material is shown in Table 1. Make the material N 2 Under the physical adsorption, the adsorption-desorption curve was obtained. The specific surface area...

Embodiment 2

[0032] Weigh 100g of sodium lignosulfonate, make it into an aqueous solution with a mass concentration of 30%, add 75g of a mass fraction of 37% formaldehyde solution into a pressure-resistant polyester bottle, add 10g of SBA-15 as a template, mix, stir, and add to the reaction Mass fraction is 35g of hydrochloric acid of 37% in container, stirs until solution mixes, airtight, is placed in 100 ℃ of ovens and reacts 24h. Then dry the prepared black material at 110°C, grind, dry, grind, treat with hydrofluoric acid at room temperature for more than 12 hours to remove the template, and treat with 1M sulfuric acid for 2 hours to ensure that the sodium ions are completely exchanged, and wash until there is no sulfate. Ions, drying, that is, porous biomass acidic material. Neutralization titration, the acid content that obtains this material is shown in Table 1. Make the material N 2 Under the physical adsorption, the adsorption-desorption curve was obtained. The specific surface...

Embodiment 3

[0034] Weigh 100g of sodium lignosulfonate, make it into an aqueous solution with a mass concentration of 30%, add 75g of a mass fraction of 37% formaldehyde solution into a pressure-resistant polyester bottle, add 100g of 30%wt silica sol with different particle sizes as a template, Mix and stir, and dropwise add 35 g of hydrochloric acid with a mass fraction of 37% to the reaction vessel, stir until the solution is uniformly mixed, airtight, and place in a 100° C. oven for reaction for 24 hours. Then dry the prepared black material at 110°C, grind, dry, grind, treat with hydrofluoric acid at room temperature for more than 12 hours to remove the template, and treat with 1M sulfuric acid for 2 hours to ensure that the sodium ions are completely exchanged, and wash until there is no sulfate. Ions, drying, that is, porous biomass acidic material. Neutralization titration, the acid content that obtains this material is shown in Table 1. Make the material N 2 Under the physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com