Foam material based on suspended polyvinyl chloride resin and preparation method thereof

A technology of polyvinyl chloride resin and foam materials, which is applied in the field of foam materials, can solve the problems of the deviation between the composition of foam materials and the design composition, the formation of wet powder materials, and the deterioration of the uniformity of foam materials, so as to reduce the production cost. Effects of cost, reduced time, improved quality and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

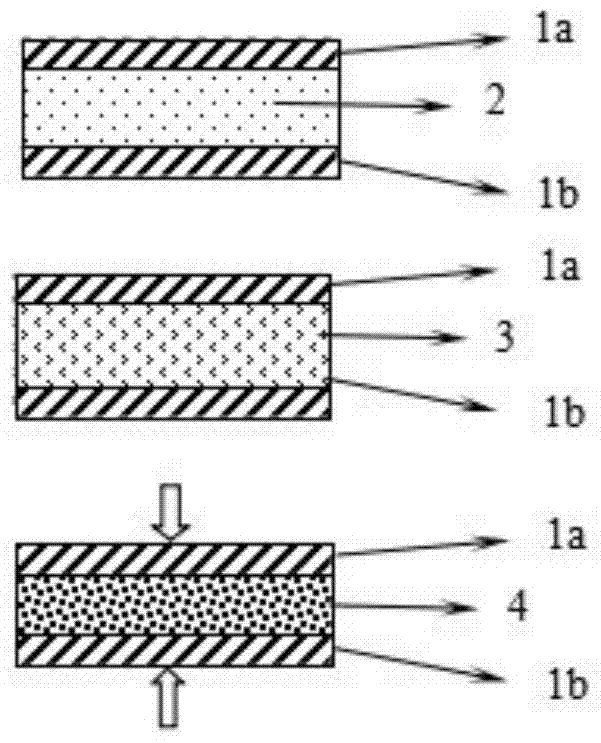

[0046] The preparation method of the above-mentioned foam material based on suspended polyvinyl chloride resin may further comprise the steps:

[0047] Step 1. After weighing the above-mentioned components according to the composition and parts by weight, mix them uniformly at room temperature to obtain a mixed material;

[0048] Wherein, after weighing each component according to the composition and parts by weight, when the component contains a catalyst, and the catalyst contains N', N", N"'-tris(dimethylaminopropyl) symmetrical hexahydrotriazine, First mix the isocyanate and acid anhydride evenly to obtain the mixture, then pour the mixture into the container with the catalyst, in order to make the isocyanate and the catalyst fully contact, generally pour it quickly, after mixing evenly, then pour it into the container with the catalyst Add loose PVC suspension resin, PVC paste resin, foaming agent and epoxy compound, mix evenly at room temperature to obtain a mixed materia...

Embodiment 1

[0074] The foam material based on suspended polyvinyl chloride resin consists of: 50 parts by weight of TDI, 15 parts by weight of phthalic anhydride, 100 parts by weight of loose PVC suspension resin, 5 parts by weight of bisphenol A glycidyl ether, 0.02 parts by weight of DC193 , 5 parts by weight of AIBN and 1 part by weight of blowing agent H.

[0075] The preparation method of above-mentioned foam material:

[0076] 50 parts by weight of TDI, 15 parts by weight of phthalic anhydride, 100 parts by weight of PVC paste resin, 5 parts by weight of bisphenol A glycidyl ether, 0.02 parts by weight of DC193, 5 parts by weight of AIBN and 1 part by weight of blowing agent H room temperature Mix evenly to obtain a mixed material;

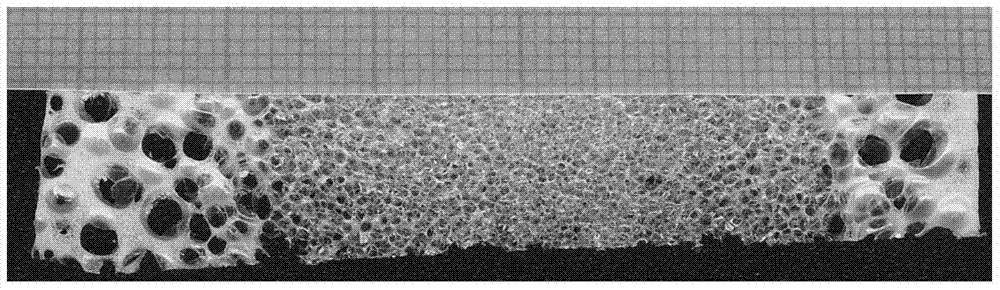

[0077] Add the above-mentioned mixed materials into a mold with a cavity of 22mm thickness, close the mold, fix the mold with a flat hot press, preheat at 80°C for 20min, then foam and press at a temperature of 175°C and pressurize to 16MPa, and keep i...

Embodiment 2

[0081] The foam material based on suspended polyvinyl chloride resin consists of: 30 parts by weight of MDI, 40 parts by weight of maleic anhydride, 20 parts by weight of succinic anhydride, 100 parts by weight of loose PVC suspension resin, and 10 parts by weight of trimethylol glycidyl ether , 10 parts by weight of epoxy soybean oil and 15 parts by weight of blowing agent H.

[0082] The preparation method of above-mentioned foam material:

[0083] With 30 parts by weight of MDI, 40 parts by weight of maleic anhydride, 20 parts by weight of succinic anhydride, 100 parts by weight of loose type PVC suspension resin, 10 parts by weight of trimethylol glycidyl ether, 10 parts by weight of epoxy soybean oil and 15 parts by weight of The foaming agent H is mixed uniformly at room temperature to obtain a mixed material;

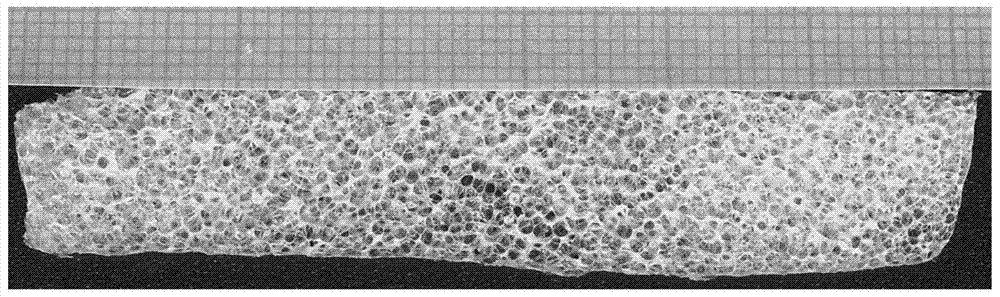

[0084] Add the above-mentioned mixed materials into a mold with a cavity of 22 mm in thickness, close the mold, fix the mold with a flat hot press, preheat at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com