Lightning-proof cable for communication base station

A technology for communication base stations and cables, applied in the field of lightning protection cables for communication base stations, can solve the problems of difficult separation of insulated wire cores, increase maintenance costs, and infrequent maintenance, and achieve excellent tracking resistance, low maintenance costs, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

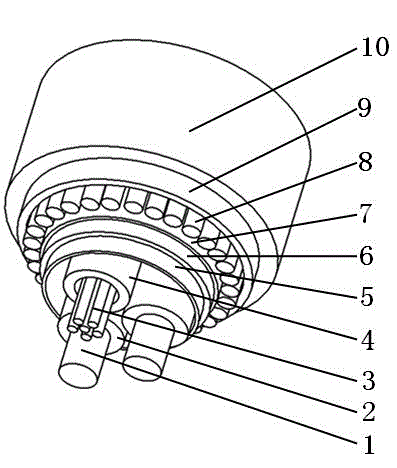

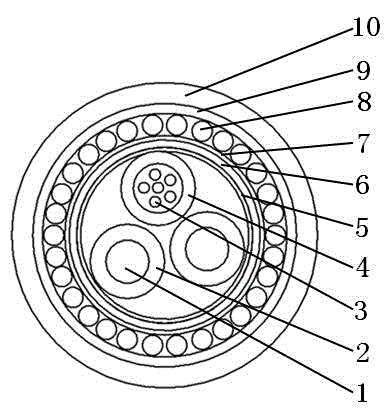

[0027] please see figure 1 and figure 2 , a lightning protection cable for communication base stations, including a cable core, an inner sheath 6, an armor layer 9, an outer sheath 10, and a grounding layer 8. The cable core is composed of an optical unit and an electrical unit, and the optical unit is composed of a loose tube 4 and a plurality of optical fibers 3 located in the loose tube, the electric unit is composed of a conductor 1 and an insulating layer 2 covering the conductor; it is characterized in that the cable core is covered with a first protective layer 5, and the inner sheath is extruded The plastic coating is outside the first protective layer, the inner sheath is covered with a second protective layer 7, the grounding layer is located outside the second protective layer, the armored layer is coated outside the grounding layer, and the outer sheath is extruded Covered outside the armor layer; the armor layer is a single-sided coated steel tape, and the surfa...

Embodiment 2

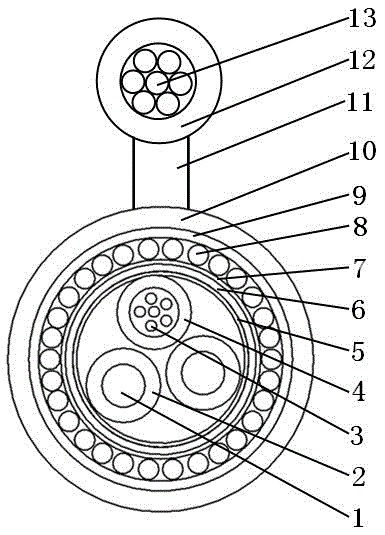

[0029] please see image 3 , and refer to figure 1 and figure 2, lightning protection cable for communication base stations, including cable core, inner sheath 6, armor layer 9, outer sheath 10, grounding layer 8, connecting rib 11, suspension wire 13, suspension wire sheath 12, the cable core is composed of optical unit The optical unit is composed of a loose tube 4 and a plurality of optical fibers 3 inside the loose tube, and the electric unit is composed of a conductor 1 and an insulating layer 2 covering the conductor; its characteristic is that the cable core is wrapped Covered with a first protective layer 5, the inner sheath is extrusion-coated outside the first protective layer, the inner sheath is covered with a second protective layer 7, the grounding layer is located outside the second protective layer, and the armored layer covers Covered outside the grounding layer, the outer sheath is extruded and coated outside the armored layer; the armored layer is a singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com