Automatic compaction density control system and automatic compaction density control method

An automatic control system, control system technology, applied in the direction of electrode manufacturing, metal rolling, manufacturing tools, etc., can solve problems affecting production efficiency, product qualification rate, unfavorable for lithium ion insertion and extraction, etc., to reduce manual intervention and adjustment , automatic and stable control of compaction density, and the effect of intelligent equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The automatic control system for realizing the compaction density of pole pieces will be described below in conjunction with the embodiments.

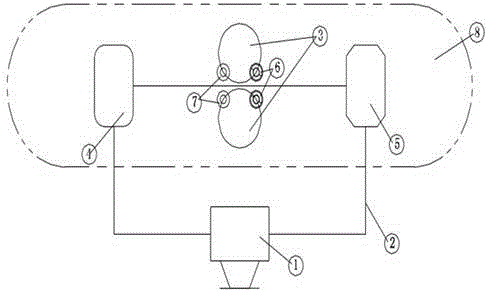

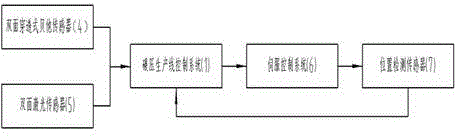

[0026] Such as figure 1 As shown, the automatic control system for pole piece compaction density of the present invention includes a rolling production line, which is mainly composed of a production line body 8 connected to a control system 1 through a network 2 .

[0027] A pair of rolling rollers 3 are arranged at the rolling position of the production line.

[0028] On the basis of the above, the present invention adds an automatic control system for rolling the pole piece by rolling rollers.

[0029] Such as figure 1 As shown, a surface density sensor 4 and a thickness sensor 5 are respectively installed before and after the rolling roller 3, a position sensor 7 is installed on the rolling roller 3, and a servo system 6 for automatically adjusting the position of the rolling roller is connected to the rolling roller 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com