Alkali resistant emulsion type defoaming agent

An emulsifying and defoamer technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of high safety performance of non-silicon defoamer, surface defects of coating film, poor wetting performance, etc., and achieves good stability and dosage. Less and more efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

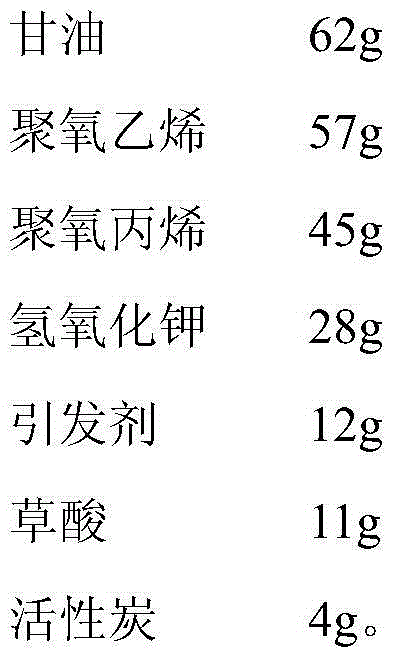

Embodiment 1

[0012]

[0013] The preparation method is as follows: glycerin is used as an initiator, and a catalyst is added to generate potassium glycerol, which is subjected to ring-opening polymerization with polyoxyethylene, and then polyoxypropylene is added to polymerize to form a block copolymer. Dissolve potassium hydroxide in glycerin to prepare potassium glycerol, put it into a polymerization kettle, heat it to 95°C, continuously put in polyoxypropylene for polymerization, adjust the reaction temperature to 95-100°C with water, and set the polymerization pressure below 500MPa. After the polymerization is completed, slowly Put in polyoxyethylene, polymerize according to the above conditions, after the reaction is completed, neutralize to neutral with oxalic acid, add activated carbon for decolorization, and obtain the finished product after filtration.

[0014] It is a non-ionic surfactant with excellent defoaming and anti-foaming functions. It is non-toxic, insoluble in water, ...

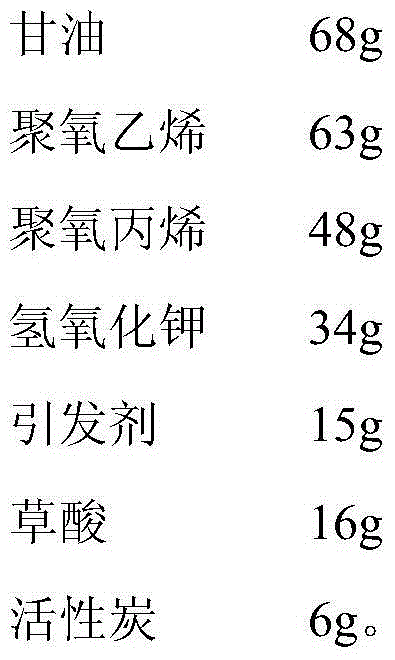

Embodiment 2

[0016]

[0017] The preparation method is the same as above.

[0018] After dissolving in water, it can reduce the surface tension of water and has defoaming effect.

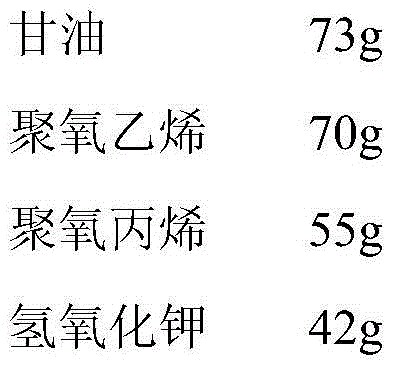

Embodiment 3

[0020]

[0021]

[0022] The preparation method is the same as above.

[0023] Under high temperature and strong alkali conditions, it can defoam rapidly and keep foam suppressed for a long time. Good stability, low consumption, high efficiency, no oil drift; widely used in paper cooking black liquor treatment, strong alkali refining agent in textile printing and dyeing industry, cleaning agent under strong alkali conditions and other high temperature and strong alkali water phase systems defoaming.

[0024] This product can replace soybean oil as a defoamer with high efficiency and non-toxicity. Concentration of 3% to 5% aqueous solution, the defoaming rate is 25 to 30 times higher than that of soybean oil. This product is used to remove a large amount of foam produced in the process of cleaning the pre-film in the industrial circulating cooling water system. This product can quickly spread to the entire surface of the foam liquid. Since the product is a self-emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com