Short oil alkyd resin and preparation method thereof

An alkyd resin, short oil degree technology, applied in the field of coatings, can solve the problems of large batch performance difference, difficult process operation, serious material loss, etc., to achieve the effect of fast curing speed, improving curing speed and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

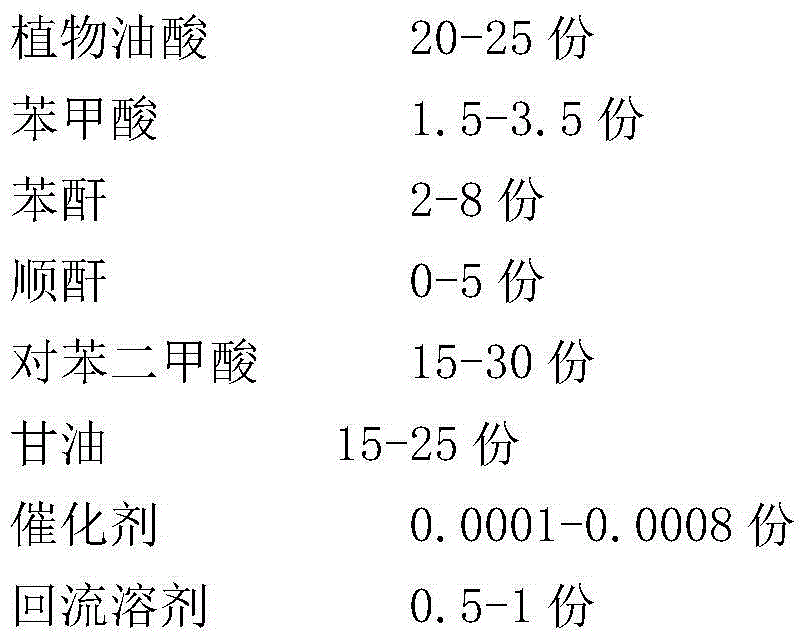

[0031] A short-oil alkyd resin synthesized by terephthalic acid, consisting of the following raw materials in parts by weight:

[0032]

[0033] Using terephthalic acid to synthesize short oil alkyd resin, the specific preparation method is as follows:

[0034] (1) first add vegetable oleic acid, glycerin, catalyst in reactor, mix and stir;

[0035] (2) Then add maleic anhydride, terephthalic acid, and benzoic acid, pass protective gas, heat up to 100°C, start stirring, continue to heat up to 160°C, turn down the flow of protective gas, and uniformly heat up to 230°C for 4 hours to keep warm For the reaction, when the acid value is detected to be 22mgKOH / g, add a reflux solvent and continue the esterification reaction at a constant temperature. When the acid value is detected to be 2.0mgKOH / g, lower the temperature to 150°C, add phthalic anhydride, and heat up to about 210°C for esterification Chemical reaction, when the acid value of the medium-controlled viscosity is qua...

Embodiment 2

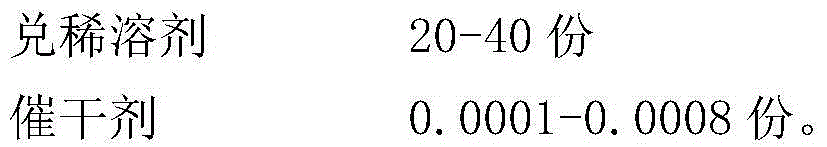

[0037] A short-oil alkyd resin synthesized by terephthalic acid, consisting of the following raw materials in parts by weight:

[0038]

[0039]

[0040] Using terephthalic acid to synthesize short oil alkyd resin, the specific preparation method is as follows:

[0041] (1) first add vegetable oleic acid, glycerin, catalyst in reactor, mix and stir;

[0042] (2) Then add maleic anhydride, terephthalic acid, and benzoic acid, pass the protective gas, heat up to 95°C, start stirring, continue to heat up to 170°C, turn down the flow rate of the protective gas, and uniformly heat up to 240°C for 4 hours to keep warm For the reaction, when the acid value is detected to be 18 mgKOH / g, add a reflux solvent and continue the esterification reaction at a constant temperature. When the acid value is detected to be 2.7 mgKOH / g, lower the temperature to 145°C, add phthalic anhydride, and heat up to 220°C for esterification Reaction, when the acid value is detected to be 6mgKOH / g, an...

Embodiment 3

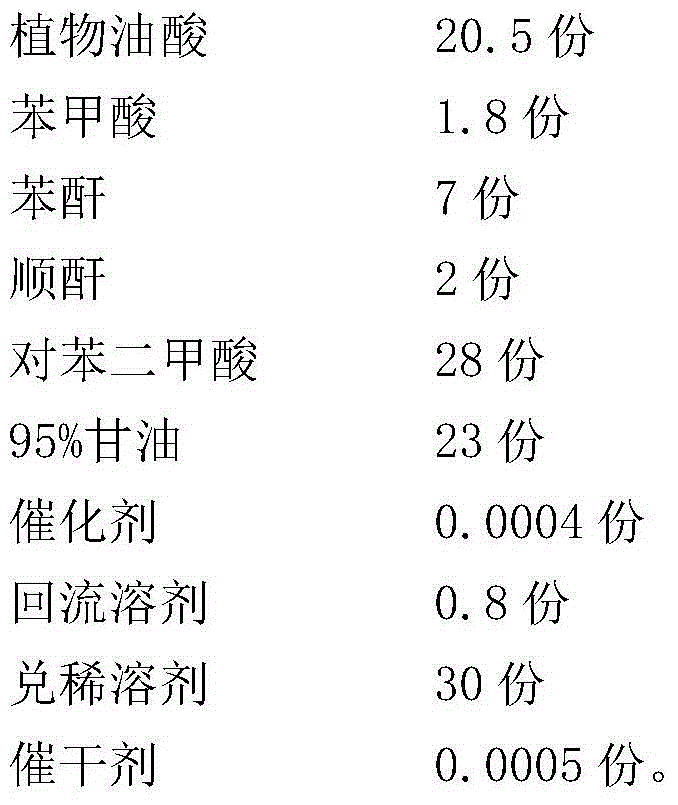

[0044] A short-oil alkyd resin synthesized by terephthalic acid, consisting of the following raw materials in parts by weight:

[0045]

[0046] Using terephthalic acid to synthesize short oil alkyd resin, the specific preparation method is as follows:

[0047] (1) first add vegetable oleic acid, glycerin, catalyst in reactor, mix and stir;

[0048] (2) Then add maleic anhydride, terephthalic acid, and benzoic acid, pass the protective gas, heat up to 110°C, start stirring, continue to heat up to 150°C, turn down the flow rate of the protective gas, and uniformly heat up to 220°C for 4 hours to keep warm For the reaction, when the acid value is detected to be 15mgKOH / g, add a reflux solvent and continue the esterification reaction at a constant temperature. When the acid value is detected to be 2.0mgKOH / g, lower the temperature to 130°C, add phthalic anhydride, and heat up to about 210°C for esterification Chemical reaction, when the acid value is detected to be 5.9mgKOH / g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com