A kind of in-situ self-grown solar spectrum selective absorption film and preparation method thereof

A solar spectrum and self-growth technology, applied in solar thermal devices, solar thermal power generation, coatings, etc., can solve the problems of complex production process, long-term work, environmental pollution by electroplating solution, etc. The effect of high photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

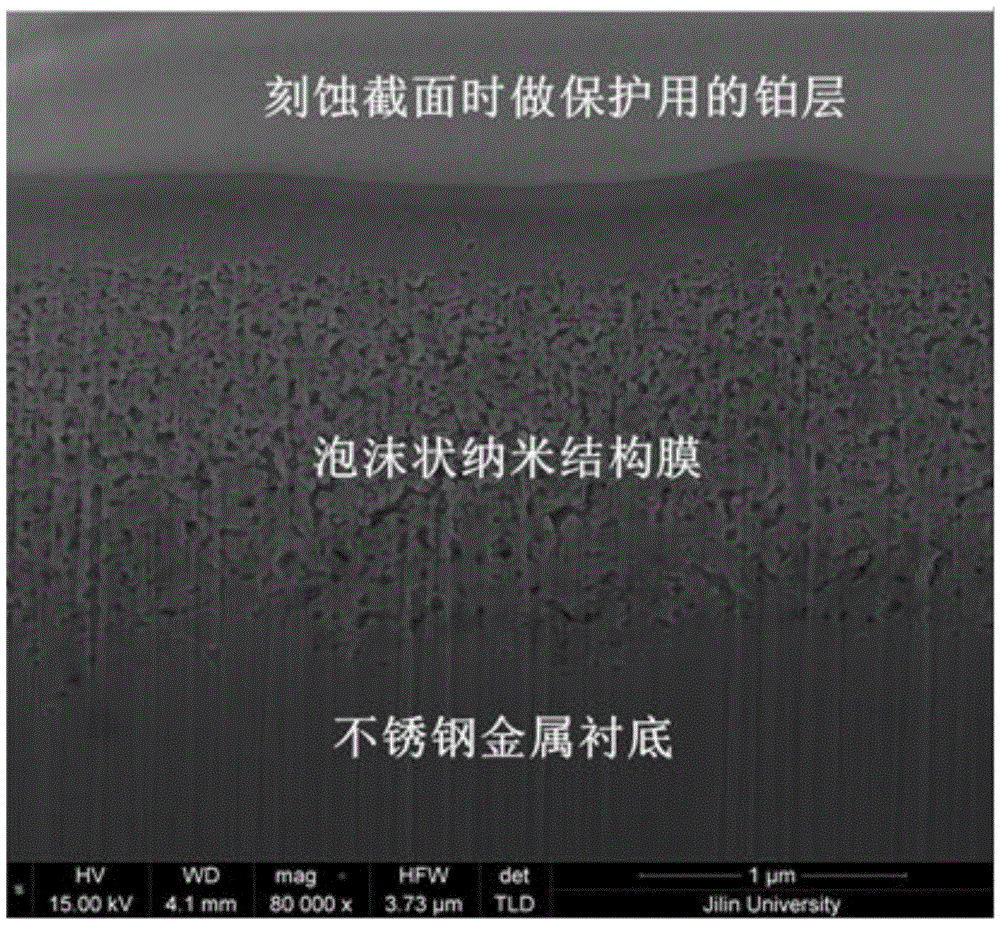

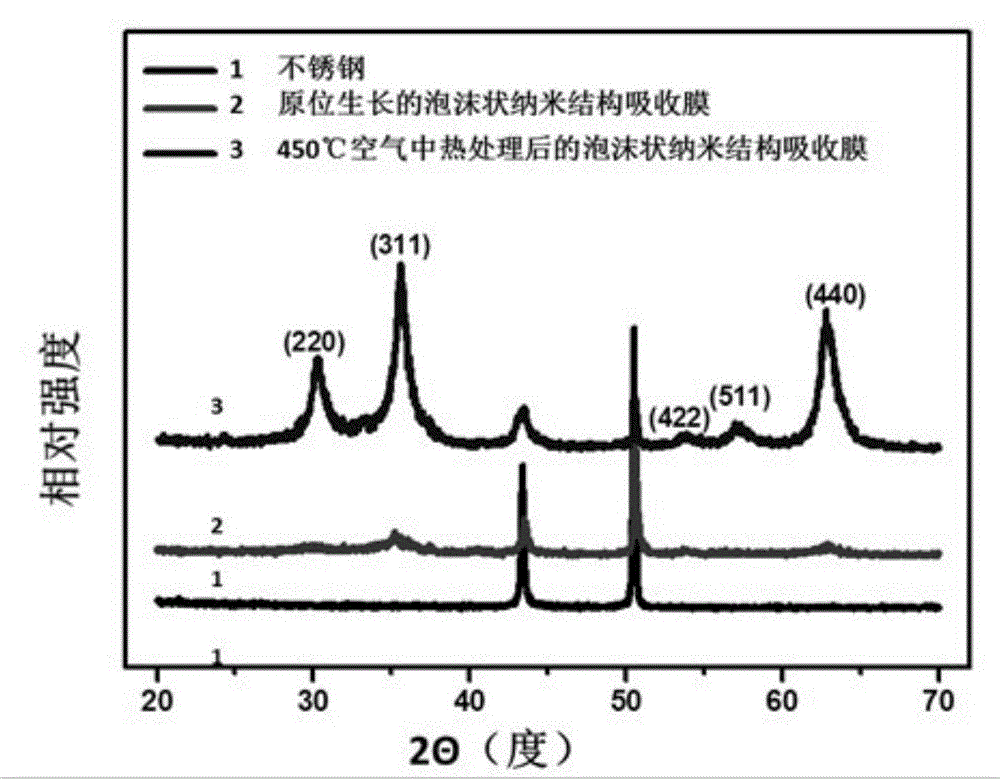

[0025] Example 1: Preparation of stainless steel substrate / foamed nanostructured absorbing film

[0026] (1) First wipe the stainless steel sheet with alcohol cotton for 12 times to make the surface of the stainless steel sheet smooth and clean, then put the stainless steel sheet into 16M NaOH solution, and then pour it into the reaction kettle together;

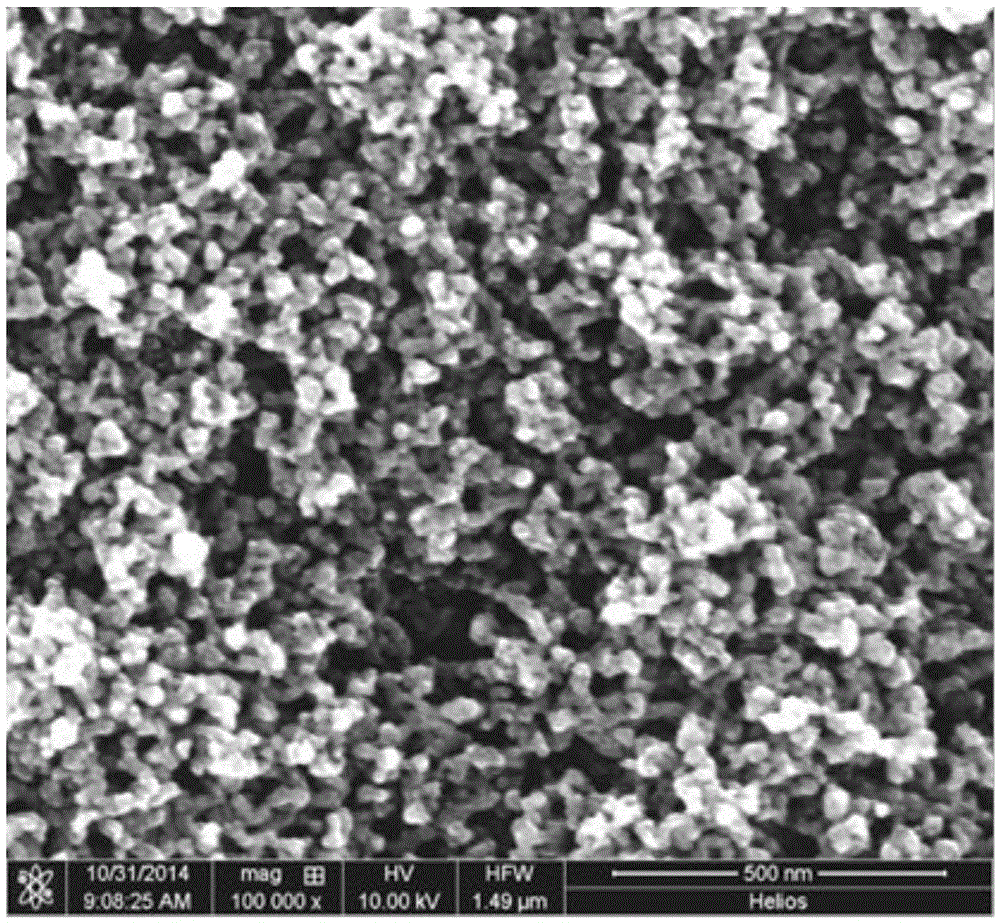

[0027] (2) Put the reaction kettle in an oven at 200 degrees Celsius for 22 hours, then take out the reaction kettle and cool it to room temperature naturally, and then ultrasonically treat it for 7 hours; finally take out the stainless steel sheet and wash it with deionized water, dry it at 90 degrees Celsius, and then A high-absorption and low-radiation solar spectrum selective absorption film with in-situ self-grown foam-like nanostructures is obtained on a stainless steel sheet. The thickness of the film is about 2.9 μm. There are relatively uniform pores accumulated in the film layer and on the surface of the film. The ...

Embodiment 2

[0033] Example 2: Preparation of stainless steel substrate / foamed nanostructured absorbing film

[0034] (1) First wipe the stainless steel sheet with alcohol cotton for 8 times to make the surface smooth and clean, then put it into 5M NaOH solution, and then pour it into the reaction kettle together.

[0035] (2) The reaction kettle was placed in an oven at 100°C for 6 hours, then the reaction kettle was taken out and cooled to room temperature naturally, the reaction product was subjected to ultrasonication for 7 hours, washed with deionized water, and dried at 20°C. The thickness of the film is about 1 μm. There are relatively uniform pores accumulated in the film layer and on the surface of the film. The particle size of the nanoparticle cluster is 35-59nm, and the size of the pores is 49-80nm. Depend on Figure 4 .2 The integral area ratio of the peaks of each element in the electron energy spectrum can be used to obtain the molar content ratio of each element on the fil...

Embodiment 3

[0036] Example 3: Preparation of stainless steel substrate / foamed nanostructured absorbing film

[0037] (1) First wipe the stainless steel sheet with alcohol cotton for 20 times to make the surface smooth and clean, then put it into 20M NaOH solution, and then pour it into the reaction kettle together.

[0038] (2) The reaction kettle was placed in an oven at 250 degrees Celsius for 40 hours, then the reaction kettle was taken out and cooled to room temperature naturally, the reaction product was subjected to ultrasonication for 25 hours, washed with deionized water, and dried at 90 degrees Celsius. The thickness of the film is about 3 μm. There are relatively uniform pores accumulated in the film layer and on the surface of the film. The particle size of the nanoparticle cluster is 20-44nm, and the size of the pores is 20-70nm. Depend on Figure 4 .3 The integral area ratio of the peaks of each element in the electron energy spectrogram can be used to obtain the molar conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com