Weather-resistant resin layer, laminate, and solar cell module

A technology of weather resistance and resin layer, which is applied in the direction of synthetic resin layered products, electrical components, semiconductor devices, etc., can solve the problems of easy penetration, weather resistance PET film discoloration, strength, and brittleness, etc., and achieve the inhibition of harmful substances and weather resistance And excellent water resistance, the effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

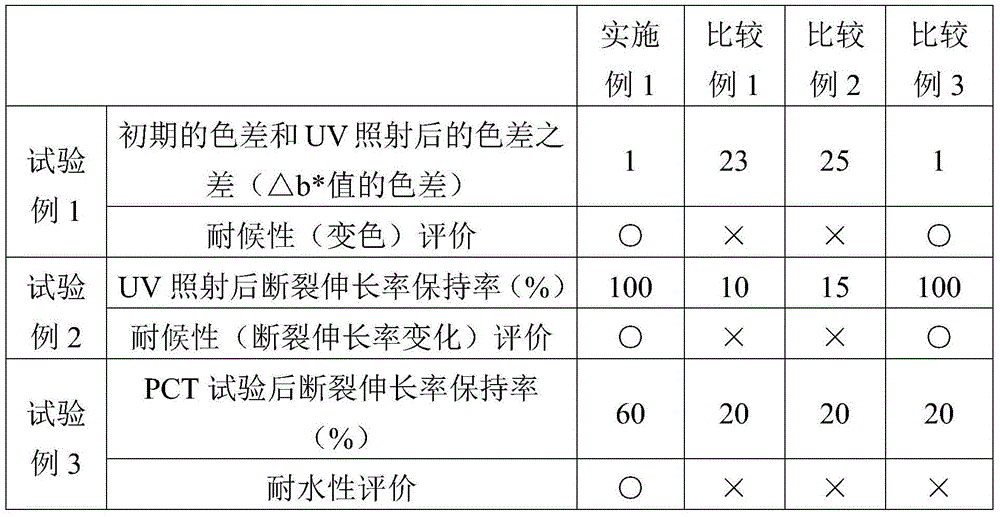

Examples

Embodiment 1

[0067] An acrylic polyol resin containing a copolymer of hydroxy (meth)acrylate and hydroxy (meth)acrylate was adopted so as to be 15% by mass with respect to 100% by mass of the polyurethane resin composition. In the acrylic polyol resin, these additives are mixed in such a manner that the polyurethane resin composition is 100% by mass, the epoxy resin is 0.5% by mass, the polycarbonate resin is 0.5% by mass, and the titanium oxide is 50% by mass, to prepare the main Agent.

[0068] A non-yellowing polyisocyanate as a curing agent is added to the prepared main agent to form a polyurethane resin composition. The content of the non-yellowing polyisocyanate in the polyurethane resin composition is 4 parts by weight with respect to 100 parts by weight of the main agent.

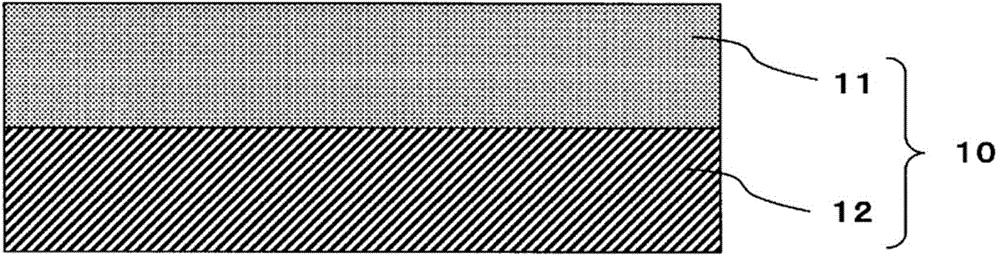

[0069] Next, a 125 μm-thick polyethylene terephthalate film (manufactured by Toyobo Co., Ltd.: brand name Toyobo Ester Film E5201) was prepared as a resin film. The polyurethane resin composition prepared as descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com