Antiasthma particles and preparation method thereof

A granule and asthma-relieving technology, applied in the field of Pingchuan granules and its preparation, can solve the problems of low utilization rate of Tianshan Rowan resources, poor patient compliance, bitter taste of asthma, etc., and achieves reduction in the amount of raw medicinal materials and good patient compliance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

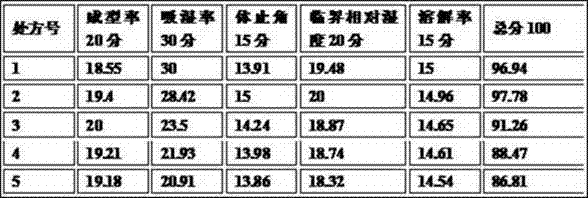

Examples

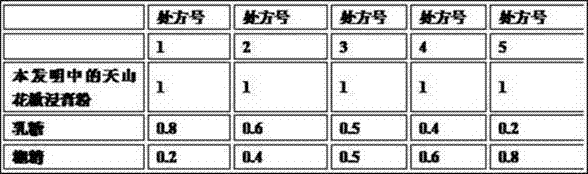

Embodiment 1

[0021] Example 1, the Pingchuan granules are obtained according to the following preparation method: the first step, the branches and leaves of Sorbus tianshanensis and the fruit of Sorbus tianshanensis are mixed at a mass ratio of 7:3, and the mixed medicinal materials are obtained after pulverization; the second step is mixed medicinal materials and 50% ethanol aqueous solution by volume percentage is 1:18, adding 50% ethanol aqueous solution to the mixed medicinal materials for extraction 3 times, the time of each extraction is 2h to 3h, and the temperature of each extraction The temperature is 80°C to 95°C. After each extraction is completed, the extract is obtained by filtration, and the extracts obtained each time are combined to obtain a blended liquid; the third step is to concentrate the blended liquid to 15% to 20% of the volume of the blended liquid Finally, the concentrated solution is obtained. At a temperature of 40°C to 50°C, add a clarifying agent of 8% of the...

Embodiment 2

[0022] Example 2, the Pingchuan granules are obtained according to the following preparation method: the first step, the branches and leaves of Sorbus tianshanensis and the fruit of Sorbus tianshanensis are mixed at a mass ratio of 7:3, and the mixed medicinal materials are obtained after pulverization; the second step is mixed medicinal materials And volume percentage is 50% ethanol water solution according to mass ratio is 1:18, add volume percentage in mixed medicinal material and be 50% ethanol water solution extraction 3 times, the time of each extraction is 2h or 3h, the temperature of each extraction The temperature is 80°C or 95°C. After each extraction is completed, the extract is obtained by filtration, and the extracts obtained each time are combined to obtain a blended liquid; the third step is to concentrate the blended liquid to 15% or 20% of the volume of the blended liquid Finally, the concentrated solution is obtained. At a temperature of 40°C to 50°C, add a c...

Embodiment 3

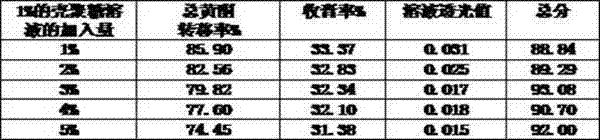

[0023] Embodiment 3, as the optimization of above-mentioned embodiment, clarification agent is the chitosan solution of 1%, and the chitosan solution of 1% is obtained as follows: get 1mL glacial acetic acid, add distilled water and dilute to 50mL, add 1.0g shell The polysaccharide was mixed evenly, and distilled water was added to make the volume to 100mL and mixed evenly. After swelling for 24 hours, a 1% chitosan solution was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com