A high recovery process for treating mine water with high sulfate and high hardness

A high-sulfate, high-recovery technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , to prevent sulfate scale formation, reduce turbidity, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

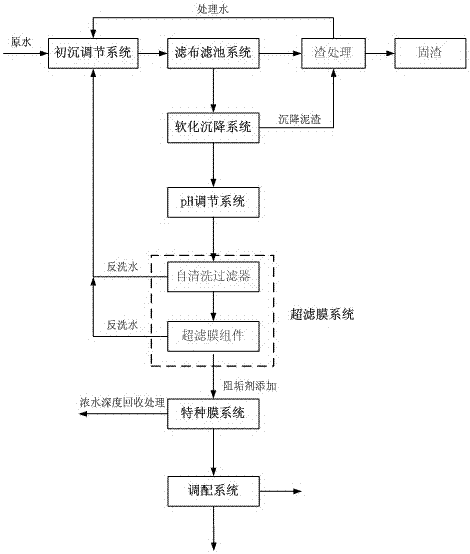

Method used

Image

Examples

Embodiment 1

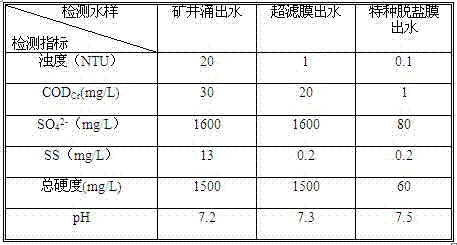

[0032] The water gushing out of an iron mine in Anhui belongs to SO4 2- -Ca 2+ Type water, rich in a large amount of sulfate and hardness, is used for industrial circulating cooling water after treatment, and the treated water volume is 450m³ / h. After the mine is adjusted by the primary sedimentation tank, it enters the ultrafiltration membrane system. A tubular ceramic ultrafiltration membrane with an average pore size of 100nm is used to remove bacteria and reduce turbidity through ultrafiltration. Cross-flow filtration is used. The transmembrane pressure difference is 0.5 MPa. Use ultrafiltration and ultrafiltration product water to carry out backwashing by automatically adding 5 mg / L NaClO. The backwashing sequence is air intake (air scrubbing)—drainage—upper backwash (simultaneous air intake)—lower backwash—forward washing, The backwash interval is 30min, the upper backwash time is 20s, the intake pressure is 0.25MPa, and the intake air volume is 5Nm 3 / h, water intake ...

Embodiment 2

[0036] Mine gushing water of an iron mine in Anhui and part of surface dust removal sewage are treated for general domestic water or public utility water. The treated water volume is 810m³ / h. According to the process, the primary sedimentation is adjusted first, and the filter cloth filter is used to filter out suspended solids. The primary sedimentation adjustment tank is uniformly distributed and mixed by hydraulic means. The filter cloth filter is a mobile vertical sheet type. The pore size of the filter cloth is about 10 μm. The operation is fully automated and can be continuously filtered. The SS removal rate is 80%. The effluent from the primary sedimentation tank enters the self-cleaning filter, and the effluent enters the hollow fiber ceramic ultrafiltration membrane with an average pore size of 50nm. Cross-flow filtration is used, the transmembrane pressure difference is 0.3 MPa, and ultrafiltration product water is used for backwashing by automatically adding 5 mg / L N...

Embodiment 3

[0040] The mine water of a large iron mine in Anhui gushes out, and after treatment, it is used for ore dressing and cooling water for mining equipment. The water volume of the pretreatment system is 1000m³ / h. According to the process, it is first adjusted by primary sedimentation, and then adjusted to pH 6.7 before entering the self-cleaning filter. The effluent is filtered by a hollow fiber polyvinylidene fluoride ultrafiltration membrane with an average pore size of 30nm. Cross-flow filtration is used, the transmembrane pressure difference is 0.08 MPa, and ultrafiltration product water is used for backwashing by automatically adding 6 mg / L NaClO. Intake)—bottom backwash—forward wash, the backwash interval is 50 minutes, the upper backwash time is 60s, the intake pressure is 0.2MPa, and the intake volume is 7Nm 3 / h, water intake 120L / m 2 • h, the backwash time is 80s, and the backwash time is 25s. The ultrafiltration effluent enters the special membrane system after addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com