Medical nylon composite pipe and preparation method thereof

A composite pipe and nylon technology, which is applied in the field of multi-component medical nylon composite pipe and its preparation, can solve the problems of poor rigidity, low hardness of single-component nylon 12, high water absorption, etc., and achieve good rigidity and good biocompatibility , the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

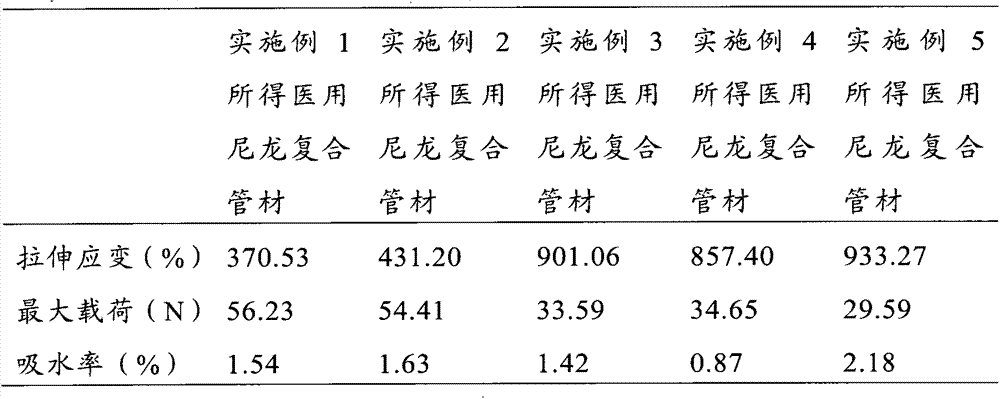

[0025] Nylon 66 (BASF, 110921-02) with a molecular weight of 1.5w and nylon 12 (BASF, 111104) with a molecular weight of 1.5w were placed in a vacuum oven at 60°C for 24 hours to remove moisture absorbed in the nylon material. Weigh 500 grams of nylon 66 and 4,500 grams of nylon 12, add them to a twin-screw extruder (SHJ-20C), extrude through twin-screw blending, granulate, and dry to obtain a particle size of 1mm. Two-component nylon composite pellets. Weigh a certain amount of 3,000 grams of two-component nylon composite pellets, add them to a single-screw extruder, and prepare a product with an inner diameter of 1.3mm, an outer diameter of 1.5mm, and a wall thickness of 0.20mm by melt extrusion, cooling and shaping, and drying. mm two-component nylon composite tubing, which can be used in the field of medical devices such as balloon catheters. The properties of the medical nylon composite pipe prepared in this embodiment are shown in Table 1.

[0026] Wherein tensile stra...

Embodiment 2

[0028] Nylon 6 (BASF, 110921-01) with a molecular weight of 1.5w, nylon 66 with a molecular weight of 1.5w (BASF, 110921-02) and nylon 12 with a molecular weight of 1.5w (BASF, 111104) were placed in a vacuum at 70°C Oven drying in vacuum for 4 hours to remove moisture absorbed in the nylon material. Weigh 250 grams of nylon 6, 250 grams of nylon 66 and 4,500 grams of nylon 12, join a twin-screw extruder (SHJ-20C), extrude through twin-screw blending, granulate, and dry to obtain a A three-component nylon composite pellet. Weigh 4,000 grams of three-component nylon composite pellets, add them to a single-screw extruder, and prepare a pellet with an inner diameter of 1.5mm, an outer diameter of 1.75mm, and a wall thickness of 0.25mm through melt extrusion, cooling and shaping, and drying. Three-component nylon composite tubing, which can be used in the field of medical devices such as balloon catheters. The properties of the medical nylon composite pipe prepared in this embod...

Embodiment 3

[0031] Nylon 11 with a molecular weight of 2w (BASF, 110921-03) and nylon 12 with a molecular weight of 1.5w (BASF, 111104) were placed in a vacuum oven at 120°C for 10 hours to remove moisture absorbed in the nylon material. Weigh 2,000 grams of nylon 11 and 3,000 grams of nylon 12, add them to a twin-screw extruder (SHJ-20C), extrude through twin-screw blending, granulate, and dry to prepare a two-component nylon compound pellets. Weigh 1000 grams of two-component nylon composite pellets, add them to a single-screw extruder, and prepare a 0.25mm inner diameter, 0.5mm outer diameter, and 0.25mm wall thickness through melt extrusion, cooling and shaping, and drying. Two-component nylon composite tubing, which can be used in the field of medical devices such as balloon catheters. The properties of the medical nylon composite pipe prepared in this embodiment are shown in Table 1.

[0032]Wherein the tensile strain and the maximum load are obtained by cutting the length of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com