Regeneration method of acid washing waste acids

A technology for pickling waste acid and nitric acid, which is applied in the field of recovering iron salts and acids from pickling waste acid, can solve the problems of low recovery rate and high follow-up treatment costs, and achieve low input costs, saving treatment costs and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

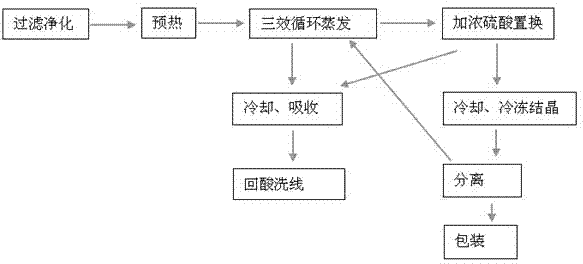

[0036] refer to figure 1 As shown, the pickling waste acid sent from the pickling waste acid workshop mainly contains hydrofluoric acid, nitric acid and iron salts, and the regeneration method of pickling waste acid comprises the following steps:

[0037] Step 1): Filtration by pumping to filter out dirt and impurities;

[0038] Step 2): The filtered and purified pickling waste acid is transported by the system pipeline to the YKZ type round hole graphite heat exchanger, and preheated at 75°C. After preheating, part of the hydrofluoric acid and nitric acid are evaporated;

[0039] Step 3): Send the preheated remaining waste acid to the III-effect evaporator for flash evaporation at 85°C to obtain the mixed steam of hydrofluoric acid and nitric acid, the mixed liquid of saturated iron salt, hydrofluoric acid and nitric acid, The Ⅲ effect evaporator is a falling film bidirectional anti-corrosion evaporator, the tube side is F4 impregnated graphite, and the shell side is steel-l...

Embodiment 2

[0046] The pickling waste acid sent from the pickling waste acid workshop mainly contains hydrofluoric acid, nitric acid and iron salt, and the regeneration method of pickling waste acid includes the following steps:

[0047] Step 1): Filtration by pumping to filter out dirt and impurities;

[0048] Step 2): The filtered and purified pickling waste acid is transported by the system pipeline to the YKZ type round hole graphite heat exchanger, and preheated at 85°C. After preheating, part of the hydrofluoric acid and nitric acid are evaporated;

[0049] Step 3): Send the preheated remaining waste acid to the III-effect evaporator for flash evaporation at 85°C to obtain the mixed steam of hydrofluoric acid and nitric acid, the mixed liquid of saturated iron salt, hydrofluoric acid and nitric acid, The Ⅲ effect evaporator is a falling film bidirectional anti-corrosion evaporator, the tube side is F4 impregnated graphite, and the shell side is steel-lined ETFE;

[0050] Step 4): T...

Embodiment 3

[0056] The pickling waste acid sent from the pickling waste acid workshop mainly contains hydrofluoric acid, nitric acid and iron salt, and the regeneration method of pickling waste acid includes the following steps:

[0057] Step 1): Filtration by pumping to filter out dirt and impurities;

[0058] Step 2): The filtered and purified pickling waste acid is transported by the system pipeline to the YKZ type round hole graphite heat exchanger, and preheated at 80°C. After preheating, part of the hydrofluoric acid and nitric acid are evaporated;

[0059] Step 3): Send the preheated remaining waste acid to the III-effect evaporator for flash evaporation at 85°C to obtain the mixed steam of hydrofluoric acid and nitric acid, the mixed liquid of saturated iron salt, hydrofluoric acid and nitric acid, The Ⅲ effect evaporator is a falling film bidirectional anti-corrosion evaporator, the tube side is F4 impregnated graphite, and the shell side is steel-lined ETFE;

[0060] Step 4): T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com