Processing method of kidney beans boiled and cooked together with rice

A processing method and kidney bean technology, which is applied in the field of grain deep processing, can solve the problems of not being able to maintain the appearance of kidney bean intact grains, falling off, and separation of watercress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

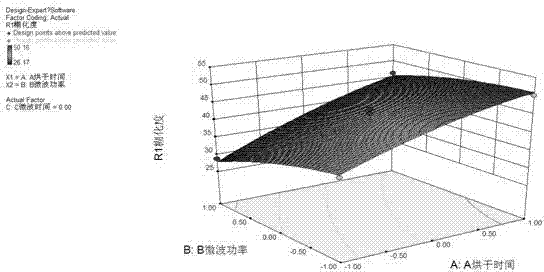

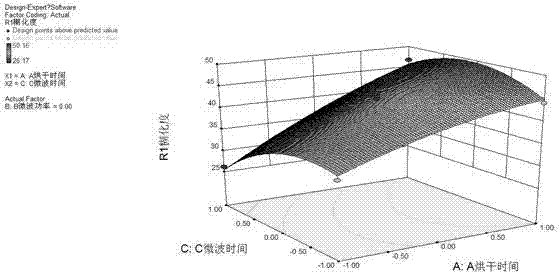

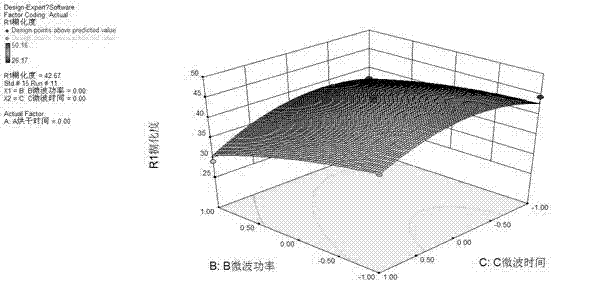

Image

Examples

Embodiment 1

[0021] 1 Materials and methods.

[0022] 1.1 Materials and reagents.

[0023] Kidney beans, commercially available; α-amylase, provided by Novozymes; hydrochloric acid, analytically pure; DNS reagent, self-made.

[0024] 1.2 Main instruments and equipment

[0025] MY-13SS506A Pressure Cooker Midea Company

[0026] HH-2 digital display constant temperature water bath Changzhou Aohua Instrument Co., Ltd.

[0027] BS210S electronic balance German Sartorist Instrument Co., Ltd.

[0028] HR2841 multi-function pulverizer PHLIPS company

[0029] SRR-FC1281S Type Constant Temperature Refrigerator Sanyo Refrigerator Manufacturing Factory

[0030] UV2300 UV-Vis Spectrophotometer Shanghai Tianmei Scientific Instrument Co., Ltd.

[0031] EM-L530TB Microwave Oven Hefei Royalstar Sanyo Electric Co., Ltd.

[0032] BYXX-50 smoke box Hangzhou Aibo Technology Engineering Co., Ltd.

[0033] MB35 Moisture Analyzer American Ohaus Co., Ltd.

[0034] Rice Cooker Midea Company.

[0035] 1.3...

Embodiment 2

[0057] Take 500 g of kidney beans in a container, add water at a temperature of 50°C, make the water cover the surface of the kidney beans, put them in a water bath for constant temperature soaking for 15 minutes, turn them over every 5 minutes to make the water evenly distributed in the kidney beans, and add water continuously, Keep the water submerged on the surface of the kidney beans until the end of soaking after 15 minutes; then drain and boil in low-pressure water under the conditions of 70kpa, 8min, and a ratio of material to liquid of 1:2.5; then take it out and drain for drying treatment. The method is: hot air drying at 60°C for 60 minutes, microwave power at 800w for 6 minutes. The moisture content after drying is 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com