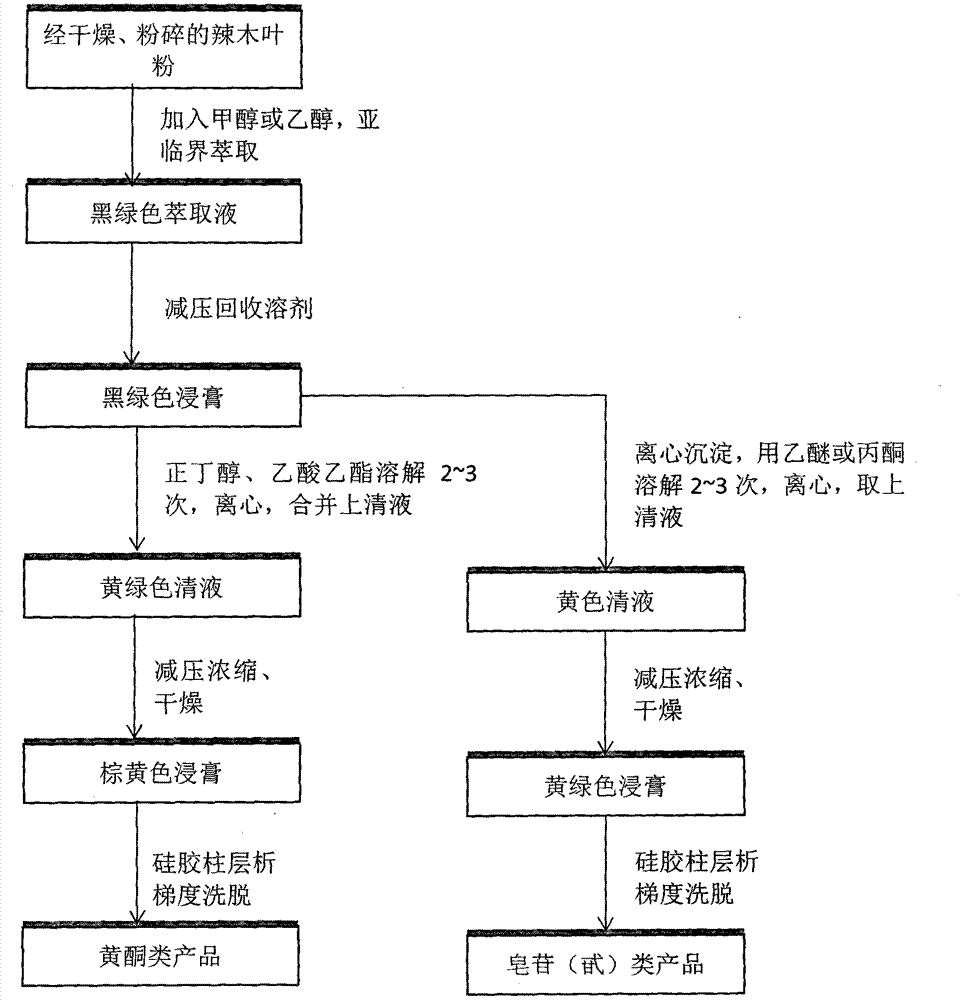

Process for extracting and separating moringa oleifera flavones and saponin from moringa oleifera leaves

A technology of Moringa flavonoids and Moringa leaves, applied in the field of separation and purification of Moringa natural products, can solve the problems of long operation period, large loss of extracted components, inconvenient operation, etc., and achieve less impurity content, short extraction time, and short operation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get 1 kg of Moringa oleifera leaves, crush them through a 300-mesh sieve, put them into a filter frame, put them into a subcritical extraction kettle, add methanol extractant, adjust the solid-liquid ratio to 1:5, adjust the extraction temperature to 100°C, and the extraction pressure to 0.35MPa. 3 times, 15 min each time, the extract was put into a solvent recovery kettle, the solvent was recovered under reduced pressure, and dried in vacuum to obtain a black-green extract. The fat-soluble components such as chlorophyll were removed from the extract with dichloromethane, and different flavonoids were extracted with ethyl acetate and n-butanol, respectively, three times each; the raffinate was extracted three times with ether. Combine the two extracts of flavonoids and concentrate under reduced pressure to obtain a brownish-yellow extract. Take an appropriate amount of the extract and put it on a silica gel column, and use the eluent to elute in a gradient from small to ...

Embodiment 2

[0028] Get 1 kg of Moringa oleifera leaves, grind through a 250-mesh sieve, put into a filter frame, put into a subcritical extraction kettle, add methanol extractant, adjust the solid-liquid ratio to 1:10, extract temperature at 140° C., extract pressure at 1.08 MPa, extract 2 Each time, extracting for 0.5h each time, the extraction liquid was put into a solvent recovery kettle, the solvent was recovered under reduced pressure, and vacuum-dried to obtain a black-green extract. The fat-soluble components such as chlorophyll were removed from the extract with dichloromethane, and different flavonoids were extracted with ethyl acetate and n-butanol, respectively, twice each; the raffinate was extracted twice with acetone. Combine the three extracts of flavonoids and concentrate under reduced pressure to obtain a yellow-green extract. Take an appropriate amount of the extract and put it on a silica gel column, and use the eluent to elute with a gradient from small to large polarit...

Embodiment 3

[0030]Get 1 kg of Moringa oleifera leaves, grind through a 200-mesh sieve, put into a filter frame, put into a subcritical extraction kettle, add ethanol extractant, adjust the solid-liquid ratio to 1: 15, extract temperature at 120 ° C, extract pressure at 0.42 MPa, and extract 3 2 times, extract 20min each time, put the extract into a solvent recovery kettle, recover the solvent under reduced pressure, and dry in vacuum to obtain a black-green extract. The fat-soluble components such as chlorophyll were removed from the extract with dichloromethane, and different flavonoids were extracted with ethyl acetate and n-butanol respectively, each extracted 3 times; the raffinate was extracted 3 times with acetone. Combine the three extracts of flavonoids and concentrate under reduced pressure to obtain a yellow-green extract. Take an appropriate amount of the extract and put it on a silica gel column, and use the eluent to elute with a gradient from small to large polarity for detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com