N, N'-alkylene bis(saturated fatty amide) and synthesis method thereof

A synthesis method and fatty amide technology are applied in the field of N,Nˊ-alkylene bis-saturated fatty amides and their synthesis, and can solve the problem of yellowing in color, difficulty in controlling the color value index of N,Nˊ-alkylene bis-saturated fatty amides, etc. problems, to achieve simple and mild reaction conditions, reduce the price of raw materials, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

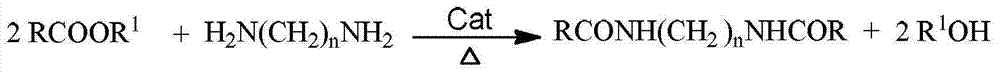

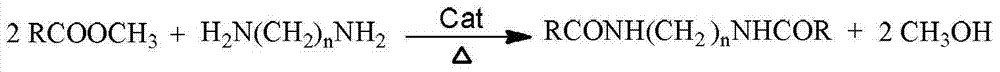

[0030] The above-mentioned N,N'-alkylene bissaturated fatty acid amide synthesis method provided by the present invention can realize the improvement of N,N'-alkylene disaturated fatty acid amide as long as at least one of solid Lewis acids such as silica gel, molecular sieves, aluminum oxide or boric acid is used as a catalyst. The effect of double saturated fatty acid amide color index, in a preferred embodiment of the present invention, this synthetic method comprises the following steps:

[0031] (1) Mix the saturated fatty acid lower alcohol ester and the solid Lewis acid, and heat up under the protection of an inert gas until the saturated fatty acid lower alcohol ester is completely melted, then stir to form a mixture A; preferably, in step (1) Moderate heating to 45-100°C, preferably 55-80°C, particularly preferably 65-75°C.

[0032] (2) Under the protection of an inert gas, heat the mixture A to the first temperature, add alkyleneamine to it, and carry out the first h...

Embodiment 1

[0056] Put 107g (0.36mol) of methyl stearate raw material, 0.11g of silica gel (Sinopharm Chemical Reagent Co., Ltd., 300-400 mesh) and 0.04g of SONOX215 antioxidant into the tank of the reactor; exhaust the inside of the reactor with a vacuum pump Gas, and replaced with inert gas, repeat this at least three times, under the continuous feeding of inert gas, heat up to 75 ° C, after the methyl stearate raw material is melted; under the condition of stirring, the material in the reactor is heated up After reaching 150°C, add 5.37g of ethylenediamine (0.09mol) dropwise to the reactor for 1 hour. After the drop of ethylenediamine is completed, perform the first heat preservation reaction at 150°C for 1 hour; after the heat preservation is completed, continue to raise the temperature to 180°C, after the second heat preservation reaction for 6 hours, filter while it is hot, and recover the catalyst; then recover the excess methyl stearate raw material by vacuum distillation, keep the...

Embodiment 2

[0058] The specific operation method is the same as in Example 1, the difference is that the catalyst used is boric acid (Example 2-1), activated alumina (Sinopharm Chemical Reagent Co., Ltd.) (Example 2-2), and HY type molecular sieve (Nankai University Catalyst plant) (Example 2-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com