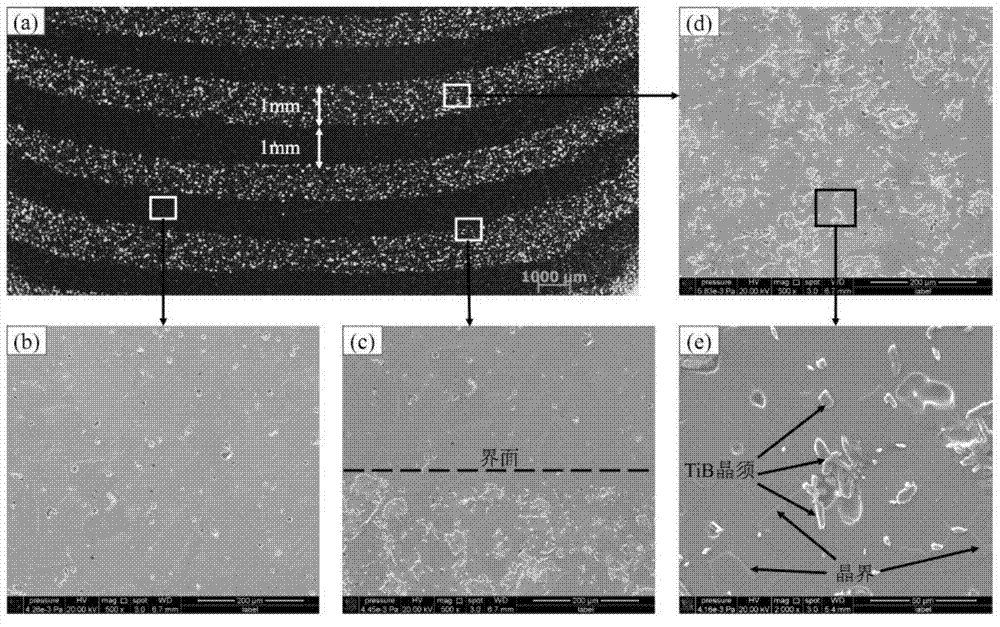

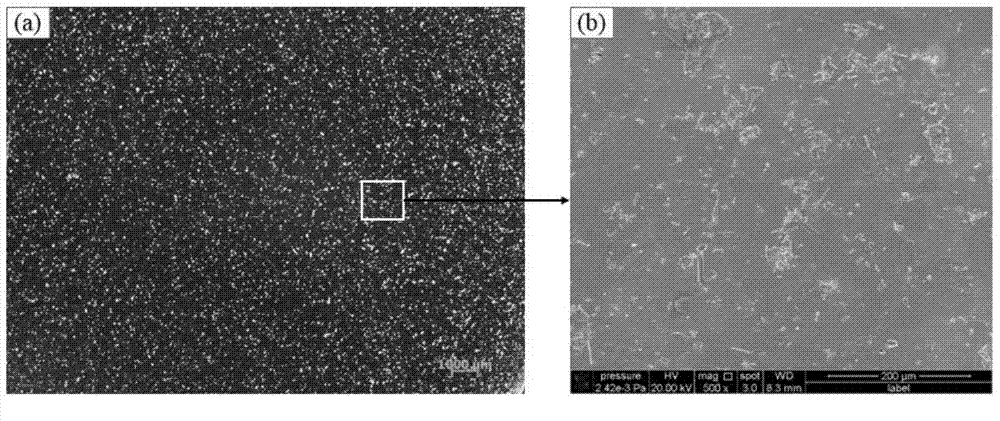

Method for preparing laminated-structured Ti-(TiB+La2O3)/Ti composite material

A technology of layered structure and composite materials, which is applied in the field of preparation of layered titanium-based composite materials, can solve the problems of poor toughness and weak interlayer bonding of layered titanium-based composite materials, so as to improve performance, reduce oxygen content, fine The effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Weigh raw materials Ti powder and LaB 6 Powder: The particle size of Ti powder used is about 100μm, LaB 6 The particle size of the powder is about 50 μm. According to the in situ reaction formula 12Ti+2LaB at high temperature 6 +3[O]=12TiB+La 2 o 3Calculate the Ti powder and LaB when the final reinforcement volume fraction is 5%, 10%, and 15% respectively 6 The proportion of powder, Ti powder mass fraction 93.4% ~ 97.8%, LaB 6 The powder mass fraction is 2.2% to 6.6%, calculated according to the size of the special mold used and weighed Ti powder and LaB under the three reinforcement volume fractions 6 The masses of powder are 46.78g, 1.05g; 45.78g, 2.09g; 44.78g, 3.14g;

[0027] Step 2. Preparation of Ti powder and LaB 6 Mixed powder of powder: the Ti powder and LaB powder weighed in step 1 6 The powder is placed in a ball mill tank, the ball-to-material ratio is 5:1, and the rotating speed is 150r / min with a rotary mixer for 15 minutes to obtain a unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com