A brushless DC motor water pump

A technology of brush DC motors and water pumps, which is applied in the direction of single motor speed/torque control, pumps, components of pumping devices for elastic fluids, etc., and can solve problems such as large vibration, low reliability, and low efficiency of water pumps , to achieve the effect of reliable lifting of the system, quick and convenient installation, and reduction of the overall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the brushless DC motor water pump of the present invention without changing the essence of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

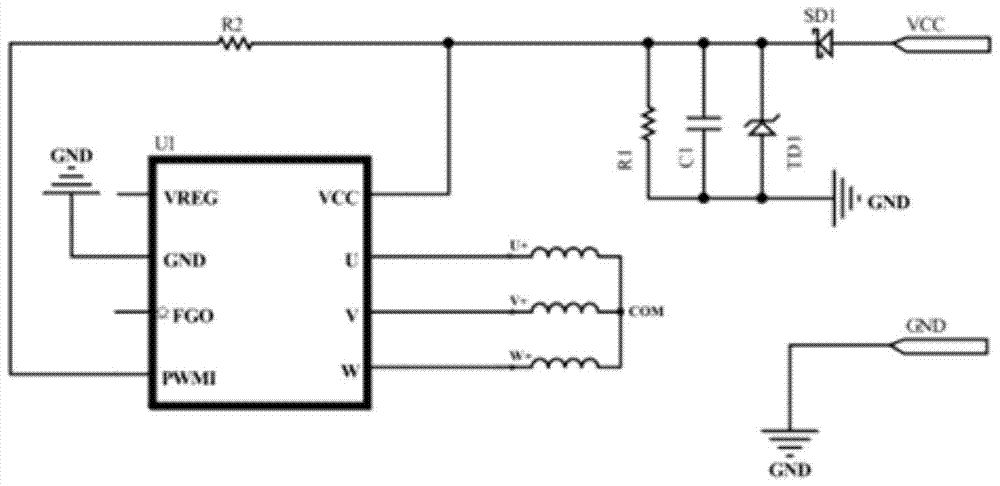

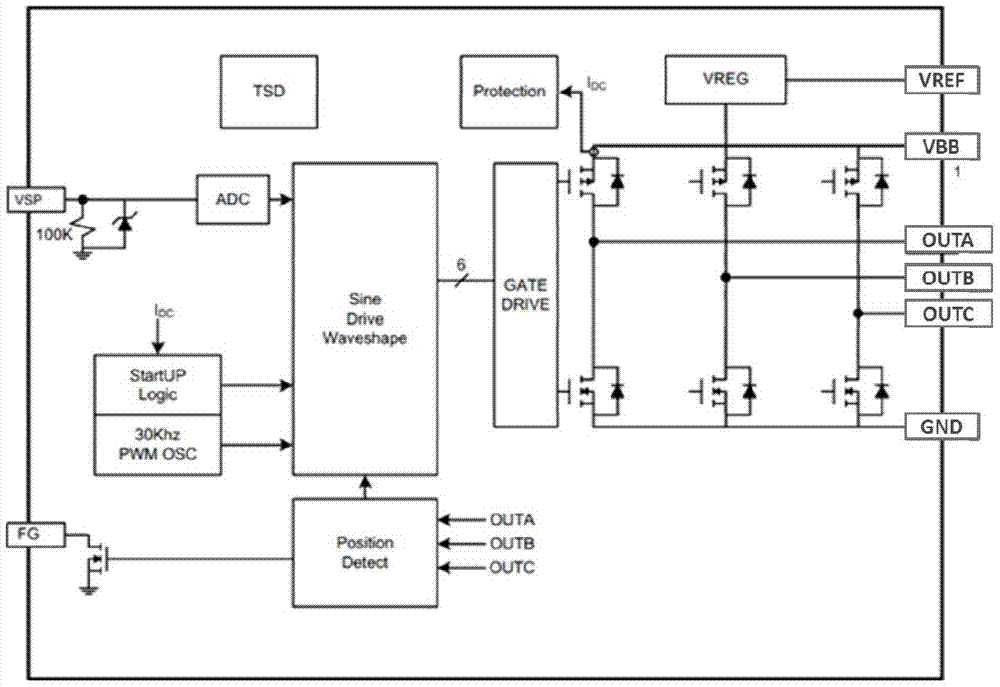

[0028] The brushless DC motor water pump of the present invention includes a drive circuit for providing electric drive and control of the brushless motor 6 . The drive circuit includes a main control chip U1, a Schottky diode SD1, a voltage transient suppression diode TD1, a main absorption capacitor C1, a discharge resistor R1, and a pull-up resistor R2;

[0029]The anode terminal of the Schottky diode SD1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com