Bioelectrochemical reaction device and bioelectrochemical reaction method for producing methane on basis of reinforcement of high-organic-matter and high-ammonia-nitrogen wastewater

A technology of chemical reaction and bioelectricity, which is applied in the field of wastewater treatment technology and bioenergy, can solve the problems of low methane production efficiency and failure to eliminate the poisoning effect of anaerobic microorganisms, and achieve the goal of reducing the concentration of ammonia nitrogen, eliminating the poisoning effect, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

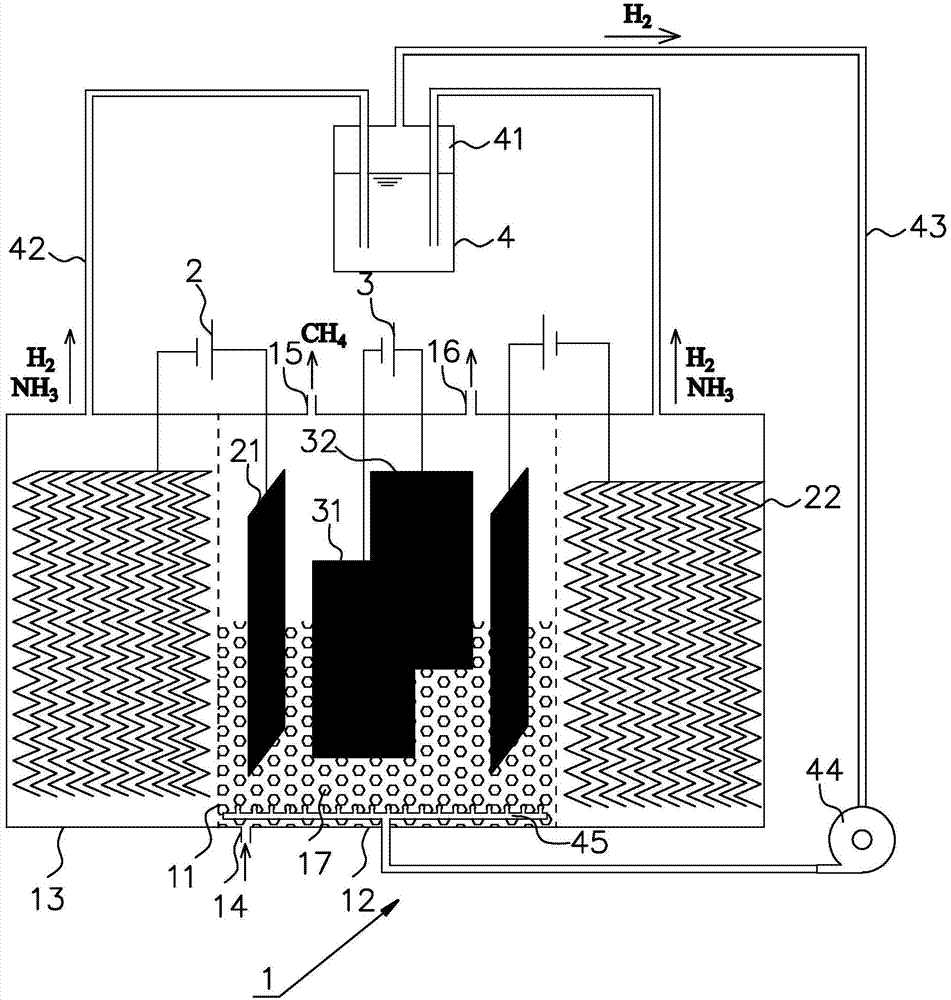

[0034] Such as figure 1 As shown, in this embodiment, a bioelectrochemical reaction device utilizing high organic matter and high ammonia nitrogen wastewater to strengthen methane production includes an electrochemical reaction tank 1, and a cation exchange membrane 11 is provided in the electrochemical reaction tank 1, and the cation exchange membrane 11 converts the electrochemistry The tank space of the chemical reaction tank 1 is divided into a first chamber 12 and two second chambers 13 respectively located on both sides of the first chamber 12 .

[0035]In this embodiment, the first chamber 12 is in the shape of a cube (10cm×10cm×10cm), and the second chamber 13 is in the shape of a cuboid (10cm×5cm×10cm).

[0036] An anode 21 is provided in the first chamber 12 , a cathode 22 is provided in the second chamber 13 , and the first power source 2 is connected between the anode 21 and the cathode 22 . In this embodiment, the first power supply is a DC stabilized power suppl...

Embodiment 2

[0044] Utilize the bioelectrochemical reaction device of embodiment 1 to produce methane with high organic matter and high ammonia nitrogen wastewater, comprising the following steps:

[0045] (1) Inject the electrolyte into the first chamber 12 and the second chamber 13, and adjust the pH of the electrolyte in the second chamber 13 to be 10;

[0046] The formula of the electrolyte is:

[0047] K 2 HPO 4 3.4g / L;

[0048] K H 2 PO 4 4.4g / L;

[0049] NaHCO 3 2g / L;

[0050] NH 4 Cl 0.1g / L;

[0051] NaCl 0.5g / L;

[0052] MgSO 4 ·7H 2 O 0.1g / L;

[0053] (2) Connect the second power supply 3, inoculate anaerobic sludge in the first chamber 12, the inoculation concentration is 15g / L, and the microorganisms hang film in the first chamber 12 for 7 days;

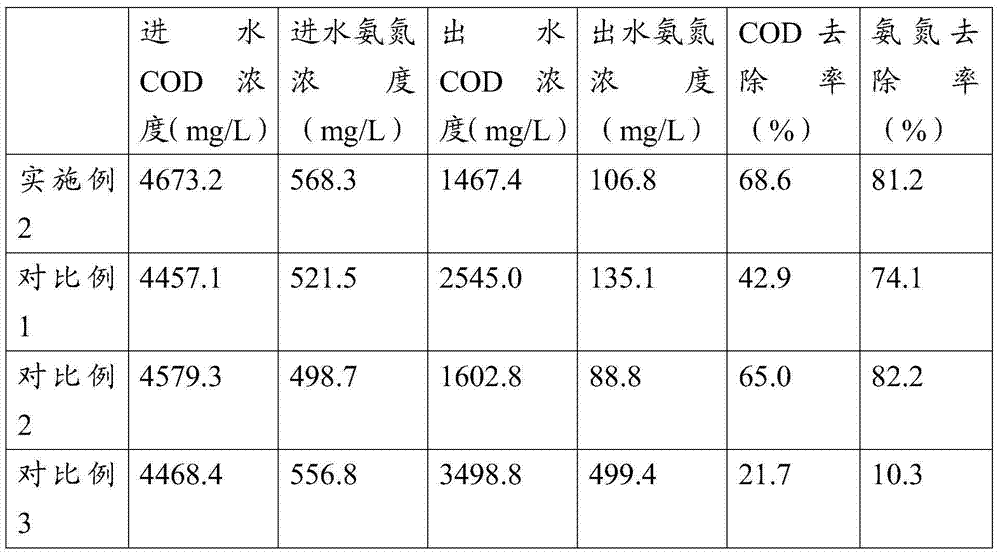

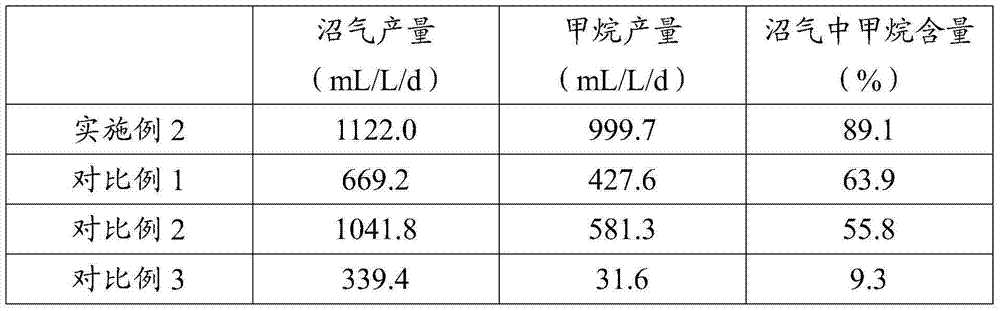

[0054] (3) After the film-hanging is completed, connect the first power supply 2, and send the high-organic high-ammonia-nitrogen wastewater from which dissolved oxygen has been removed into the first chamber 12, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com