Method for improving leaching rate of calcification roasting vanadium slag and improving filtering effect

A technology for calcification roasting and filtering effect is applied in the fields of improving the leaching rate of calcification roasting vanadium slag and improving filtering effect, and can solve the problems of increasing labor cost, large total water consumption, low output and input, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

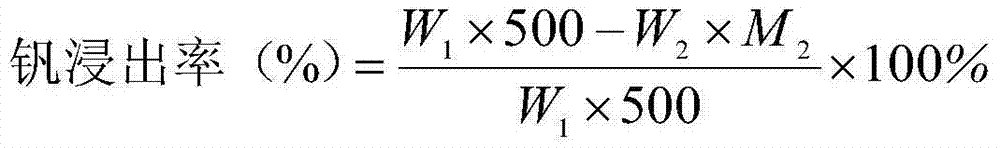

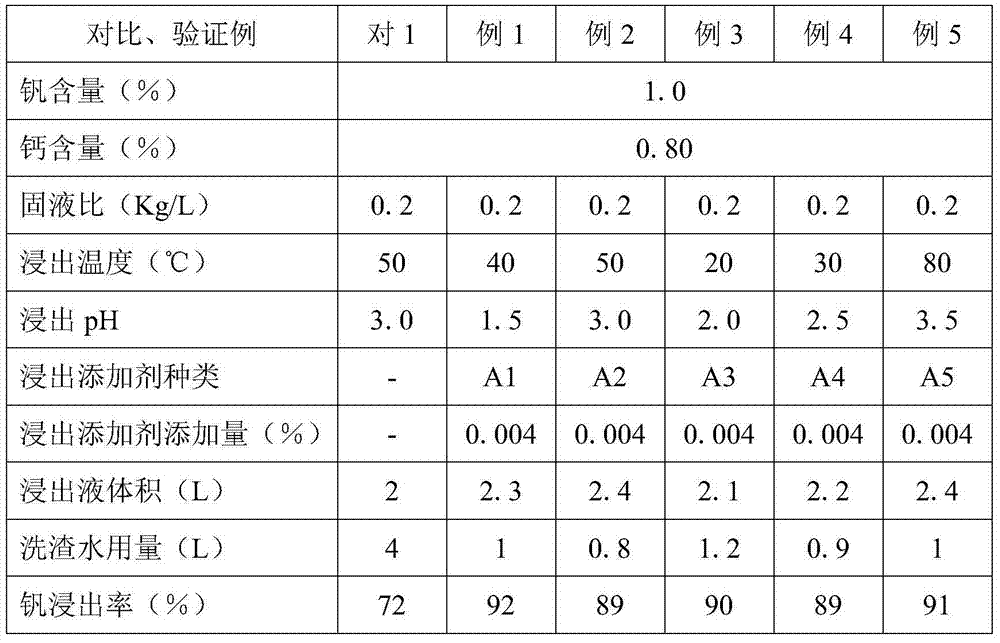

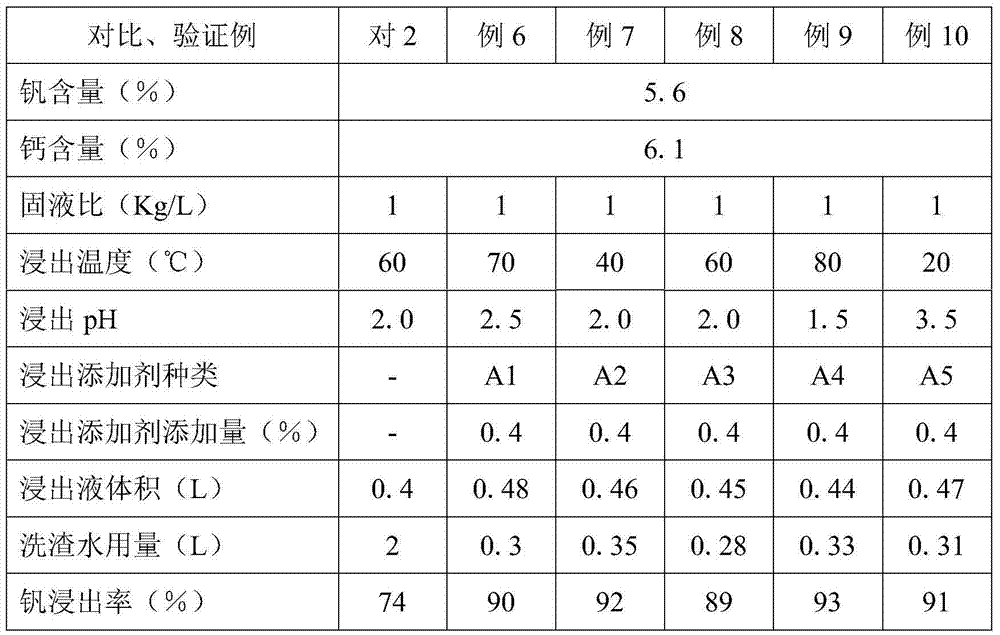

[0011] A method for improving the leaching rate of calcified roasted vanadium slag and improving the filtering effect, the method has the following steps:

[0012] (1) Grinding the calcified and roasted vanadium slag (commonly known as: clinker) and mixing it with water to make a pulp; (2) adjusting the acidity of the pulp with sulfuric acid to leach the calcified and roasted vanadium slag; (3) ) filtering and separating the leached ore pulp to obtain vanadium leaching solution and tailings to be washed; (4) leaching the tailings to be washed with water, and collecting washing water;

[0013] Usually, the particle size of the pulverized and roasted vanadium slag should not be greater than 0.12 mm. In the present invention:

[0014] In the case of the slag-washing water collected in step (4), replace the water in step (1) with slag-washing water; when the ratio of vanadium slag and slag-washing water does not meet 0.2~2kg / L , supplemented with water;

[0015] Also added leac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com