Semiconductor device and method of forming the same

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve the problems of miniaturization and miniaturization of semiconductor devices, and small unit capacitance value of capacitors, so as to improve the capacitance value per unit area, reduce process costs, and optimize electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It can be seen from the background art that the capacitance of semiconductor devices formed in the prior art is small, and it is difficult to meet the demand for capacitance of semiconductor devices, resulting in an increase in chip area, which is not conducive to meeting the development trend of device miniaturization.

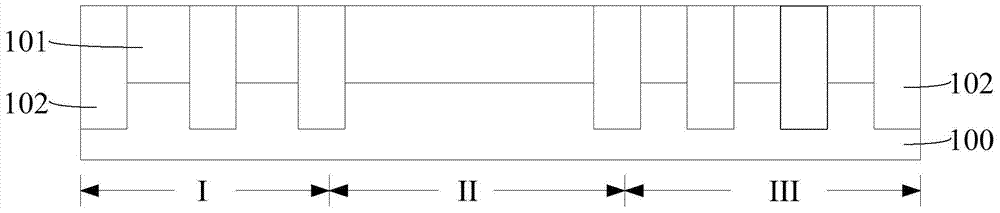

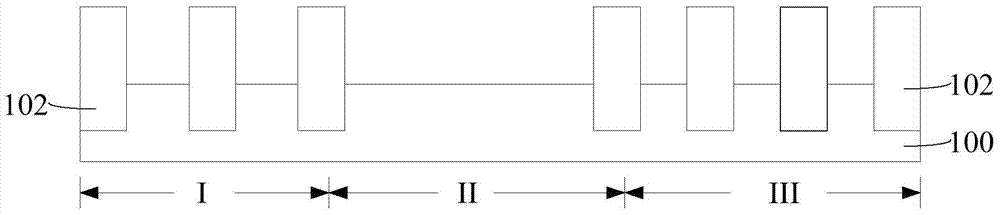

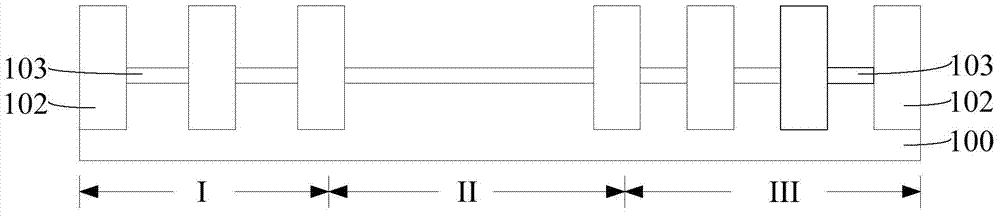

[0035] In order to solve the above problems, the manufacturing method of semiconductor devices in the prior art is studied. In order to save chip area and improve production efficiency, active regions, tunneling dielectric layers, floating gate polysilicon layers, ONO (oxide-nitride-oxide) dielectrics are used layer and the control gate polysilicon layer constitute a capacitor of the semiconductor device, the capacitor including a first capacitor and a second capacitor.

[0036] Define the active region as the lower electrode layer, the tunnel dielectric layer as the lower insulating layer, the floating gate polysilicon layer as the middle electrode lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com