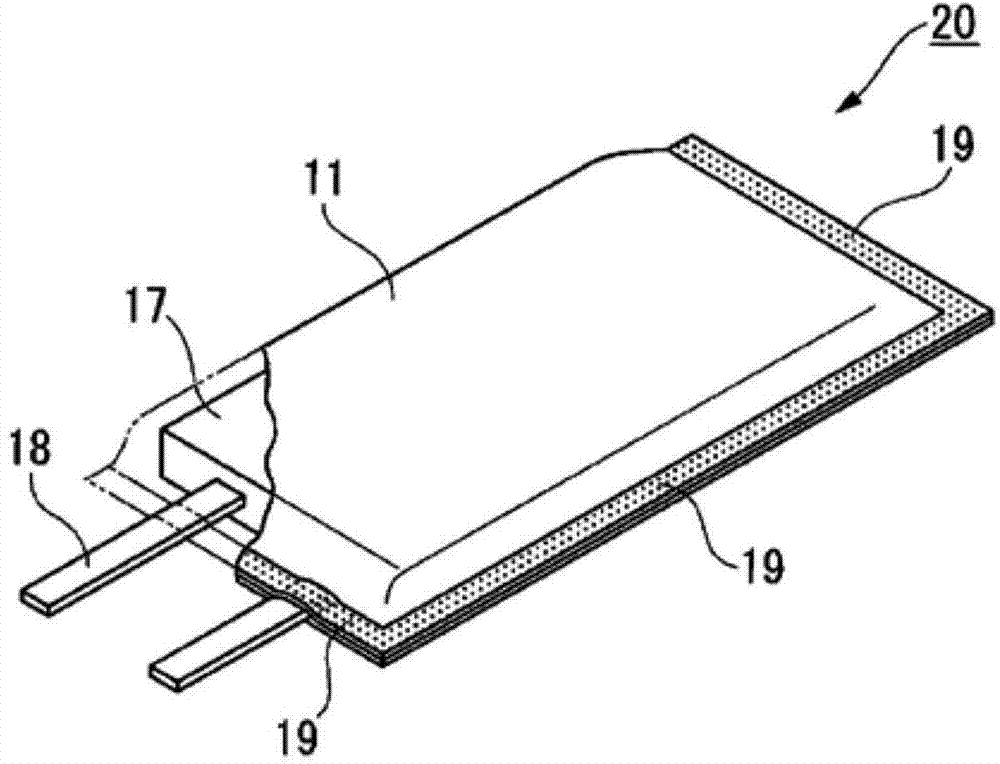

Electrode lead wire member for nonaqueous batteries

A technology for electrode leads and components, which is applied in the field of electrode lead components, can solve problems such as battery performance degradation, electrolyte leakage, and lithium-ion battery fires, and achieve the effects of less voids, less immersion, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

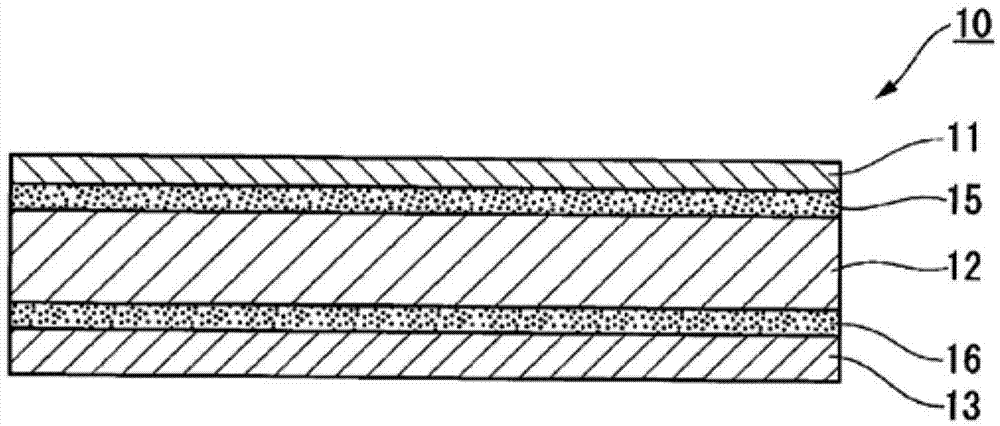

[0080]As an electrode lead member for a lithium battery, an aluminum sheet obtained by cutting an aluminum plate having a thickness of 200 μm into a size of 50 mm×60 mm was used. On the surface of the degreased and cleaned aluminum sheet, 1 wt % of an amorphous polymer having a polyvinyl alcohol skeleton containing a hydroxyl group (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G polymer resin) and 2 wt % of fluorine An aqueous solution obtained by dissolving chromium (III) is applied to both sides with a thickness of 0.5 μm using a 10 mm width type coater, and the thin film layer is laminated, and further heat-dried in an oven at 200°C to bake the resin while simultaneously The electrode lead member of Example 1 was obtained by crosslinking. At this time, it was confirmed that the thin-film coating was applied not only to the front and back surface layers of the electrode lead member of Example 1, but also to both end surfaces of the electrode lead member....

Embodiment 2

[0085] As an electrode lead part for a lithium battery, nickel sulfamate is plated with a thickness of 1 to 5 μm on the surface of a 200 μm thick copper sheet (50 mm×60 mm in size), and 1 wt % of a nickel containing An aqueous solution obtained by dissolving an amorphous polymer with a polyvinyl alcohol skeleton of a hydroxyl group (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G Polymer Resin) and 3 wt % chromium (III) fluoride was applied to a thickness of 0.5 μm. Cloth, laminated film coating, and further bake the resin by heating and drying in an oven at 200°C.

[0086] In addition, on the film coating of the electrode lead part, two layers of epoxy-modified polyethylene film (using Sumitomo Chemical Co., Ltd. After mixing BONDFAST (product name) with random copolymer polypropylene resin (product name) and polymer alloying, use a film machine to make a 100 μm film) double-sided thermal bonding, in a hot air oven at 50 ° C Keep for 48 hours. A part of ...

Embodiment 3

[0089] As an electrode lead part for a lithium battery, nickel sulfamate is plated with a thickness of 1 to 5 μm on the surface of a 200 μm thick copper sheet (50 mm×60 mm in size), and 1 wt % of a nickel containing An aqueous solution obtained by dissolving an amorphous polymer with a polyvinyl alcohol skeleton of a hydroxyl group (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G Polymer Resin) and 3 wt % chromium (III) fluoride was applied to a thickness of 0.5 μm. The cloth was laminated with a film coating, and further heated and dried in an oven at 200° C. to bake the resin.

[0090] In addition, on the film coating of the electrode lead part, two layers of epoxy-modified polypropylene film (made by Mitsui Chemicals Co., Ltd. ADMER (product name) resin, maleic anhydride modified polypropylene resin blend compound 1.5wt% epoxy compound (product name / Mitsubishi Chemical Epikote 1001) containing hydroxyl, make it with the maleic anhydride functional group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com