High-quality canned bird nest and preparing method thereof

A technology of canned bird’s nest and a production method, which is applied in the field of food processing, can solve the problems of long time consumption, decreased sensory quality, soft and rotten bird’s nest, etc., and achieves low nitrite dissolution efficiency, long soaking time, and improved texture And the effect of nutrition safety quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

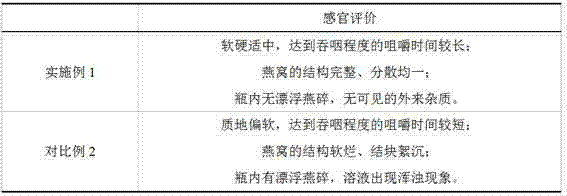

Examples

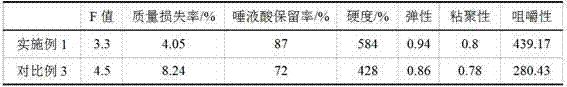

Embodiment 1

[0022] The invention discloses a high-quality bird's nest can and a production method thereof. The dried bird's nest is used as a raw material, and the bird's nest is made by adopting frequency-sweeping ultrasonic-assisted soaking technology, steaming technology, high-temperature sterilization and other processes.

[0023] The method for making the high-quality canned bird’s nest is to wash the dried bird’s nest, pick the bird’s nest, immerse with the aid of sweeping ultrasonic waves, steam, fill, sterilize at high temperature, and cool to obtain a finished product, which specifically includes the following steps:

[0024] 1) Cleaning: Soak the bird’s nest in water for 1.5 hours, then tear it apart according to its texture while rinsing, and pick out the fine hairs of the bird’s nest with tweezers after tearing;

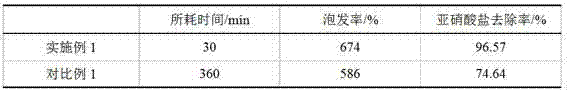

[0025] 2) Frequency-sweeping ultrasonic-assisted soaking: The cleaned bird’s nest is soaked and nitrite is removed using frequency-sweeping ultrasonic-assisted soakin...

Embodiment 2

[0031] The method for making the high-quality canned bird’s nest is to wash the dried bird’s nest, pick the bird’s nest, immerse with the aid of sweeping ultrasonic waves, steam, fill, sterilize at high temperature, and cool to obtain a finished product, which specifically includes the following steps:

[0032] 1) Cleaning: Soak the bird’s nest in clean water for 2 hours, then tear it apart according to its texture while rinsing, and pick out the fine hair of the bird’s nest with tweezers after tearing;

[0033] 2) Frequency-sweeping ultrasonic-assisted soaking: The cleaned bird’s nest is soaked and nitrite removed by using frequency-sweeping ultrasonic-assisted soaking technology. The operating parameters of the ultrasonic reactor are: ultrasonic frequency 28 ± 1kHz, processing time 35min, The treatment temperature is 40°C, and the ultrasonic power is 400W;

[0034] 3) Steaming: Drain the soaked bird's nest with a filter cloth, put it in a steamer and steam for 12 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com