Membrane electrode of membrane electrode low-voltage electrolysis type ozone generator and manufacturing method for positive and negative electrodes of membrane electrode low-voltage electrolysis type ozone generator

An ozone generator, low-voltage electrolysis technology, applied in chemical instruments and methods, electrodes, electrolysis process, etc., can solve the problems of tedious complexity, poor circulation, and difficulty in ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

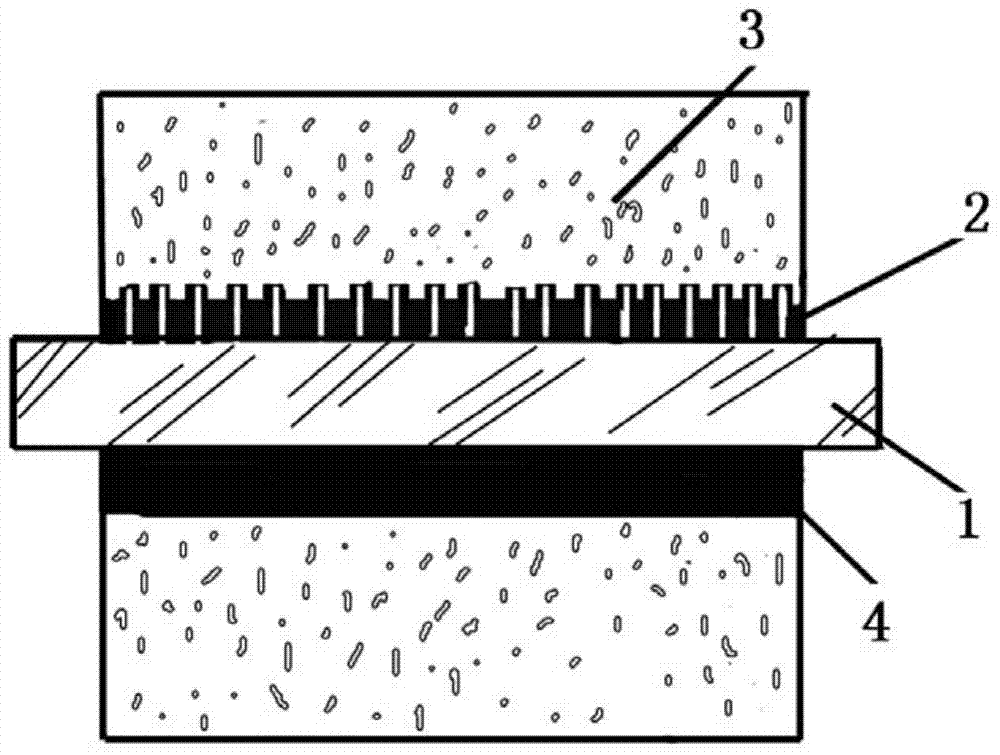

[0032] A porous titanium plate with an average particle size of 25 μm was selected as the research substrate, and it was cut into a square sheet with a size of 30 mm×30 mm.

[0033] Put the above-mentioned porous titanium plate substrate into an aqueous solution composed of potassium hydroxide, trisodium phosphate and ethylenediaminetetraacetic acid, soak at 50-60°C for 5 minutes to remove surface grease, and use 20% sulfuric acid aqueous solution at 50-60 Perform acid etching on the porous titanium plate at ℃ for 5-8 minutes to obtain a fresh substrate surface with a certain roughness on the surface.

[0034] The surface of the above-mentioned porous titanium plate base material is ground, and the diamond grinding paste with a particle size of 2.5 μm is used for grinding on a polishing machine for 2-5 minutes, and the rotational speed of the grinding disc is 300 r / h. After grinding, it was washed ultrasonically in acetone solution and deionized water solution for 5-10 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com