A carbon quantum dot based on a copper complex and a preparing method thereof

A technology of carbon quantum dots and copper complexes, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of weak interaction force and uneven distribution of composite materials Uniformity and other issues, to achieve the effect of good water solubility, high electron transmission efficiency, and wide response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

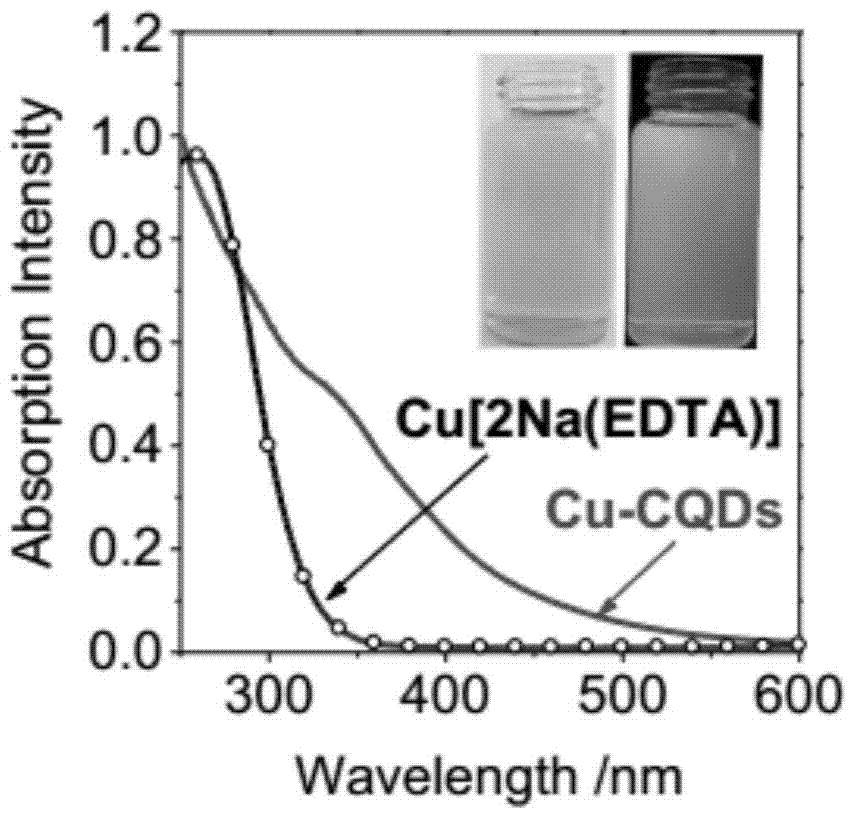

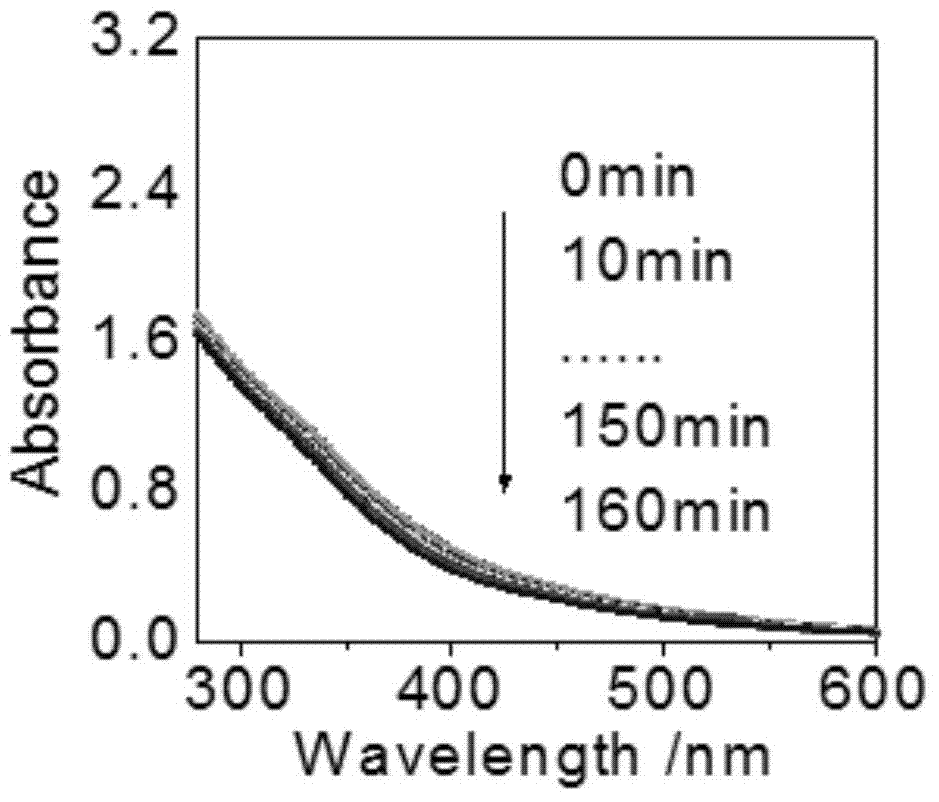

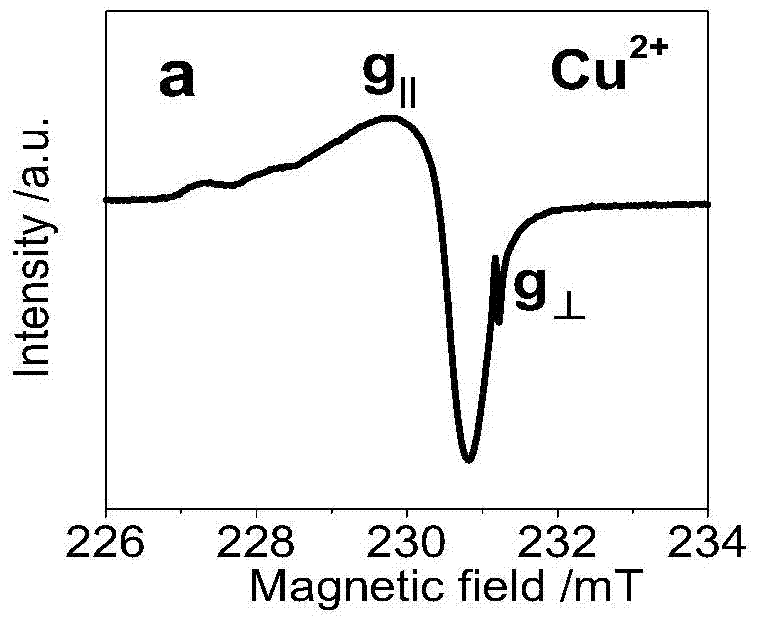

[0018] Weigh 1.6g of EDTA copper sodium salt and evenly spread it into a quartz boat, and then put the quartz boat into a tube heating furnace. N 2 Bubble for 30 minutes to remove the oxygen in the tube. After 30 minutes, start the heating device, and heat up at a heating rate of 2°C / min. After raising the temperature to 250°C, maintain a constant temperature for 2 hours, then cool down naturally, and take it out after cooling down to room temperature. The reacted sample was dissolved in 50 mL of water, and subjected to ultrasonic oscillation for 20 min in a 100 Hz ultrasonic oscillator, and centrifuged after the part easily soluble in water was completely dissolved. The insoluble material was separated by centrifugation. The centrifuged liquid is further filtered with a 0.25 μm filter membrane to remove substances larger than 0.25 μm. After concentrating the liquid obtained in the previous step, perform dialysis treatment in a 3500D dialysis bag. Part of the salts and sm...

Embodiment 2

[0020] According to the main process method in Example 1, the thermal polymerization temperature was raised to 275° C. to obtain copper complex doped carbon quantum dots, and the copper content of the carbon quantum dots was 1.5%. Used to photocatalyze 1,4-dihydropyridine with a catalytic efficiency of 50.0%

Embodiment 3

[0022] According to the main process method in Example 1, the thermal polymerization temperature was raised to 300° C. to obtain copper complex doped carbon quantum dots, and the copper content of the carbon quantum dots was 1.0%. Used to photocatalyze 1,4-dihydropyridine with a catalytic efficiency of 43.0%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com