Synchronous belt and production method thereof

A technology of synchronous belts and rubber materials, which is applied in the direction of belts, transmission belts, mechanical equipment, etc., can solve the problems affecting the stability and service life of synchronous belts, and achieve good wear resistance, improved performance, and high heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

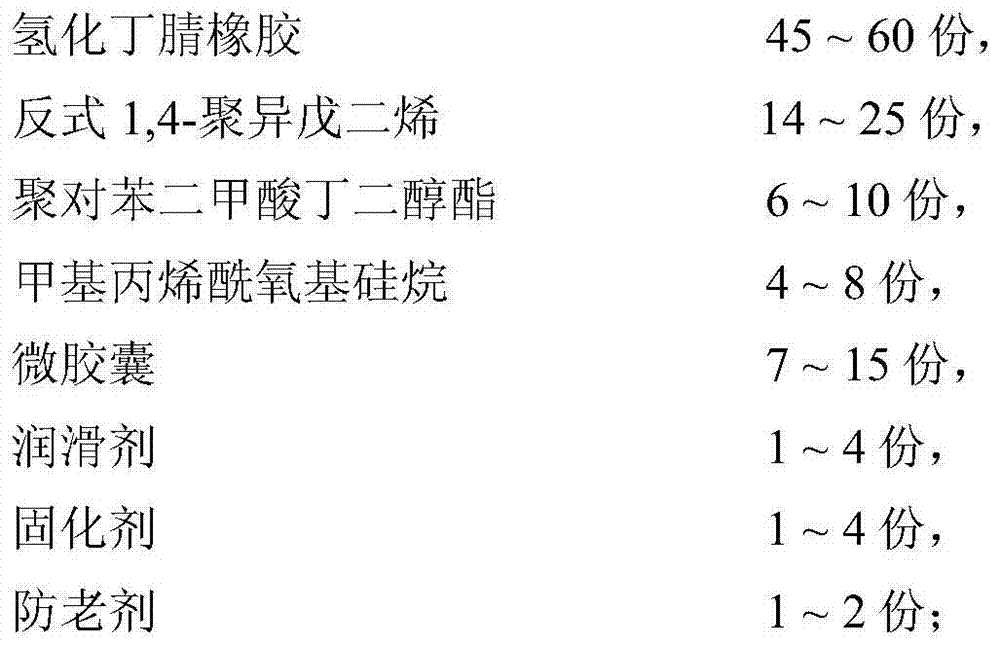

[0035] The synchronous belt of this embodiment is cast from glue and glass fiber, and the glue includes the following components by weight:

[0036]

[0037]

[0038] The preparation method of above-mentioned synchronous belt comprises the following steps:

[0039] (1) Preparation of adhesive:

[0040] (a) Add 1.1moL epichlorohydrin into a three-necked flask equipped with a constant pressure dropping funnel and a reflux condenser, immerse in an ice-water bath, start stirring, and control the temperature within 0-5°C. After stirring for 10 minutes, Start to add 0.5 mol of diglycolamine slowly. After the addition, control the temperature at 0-5°C to continue the reaction for 2 hours, and then react at room temperature for 4 hours. After the reaction, remove excess epichlorohydrin by vacuum distillation; add 300 mL of ethanol Use as a solvent, then add 25% sodium hydroxide solution dropwise at a constant speed, and finish adding dropwise for 15 minutes, then keep the tempe...

Embodiment 2

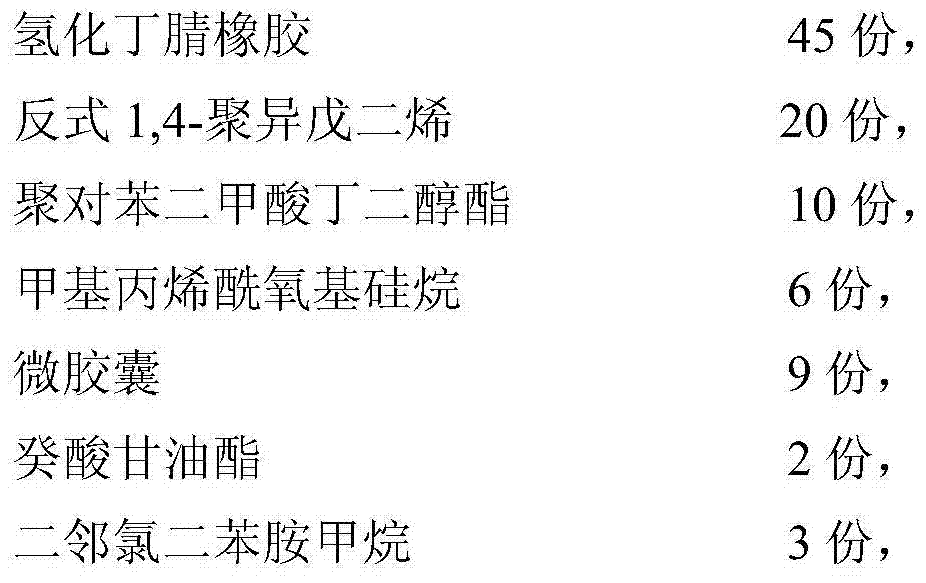

[0046] The synchronous belt of this embodiment is cast from sizing material and polyester fiber, and the sizing material includes the following components by weight:

[0047]

[0048]

[0049] The preparation method of above-mentioned synchronous belt comprises the following steps:

[0050] (1) Preparation of adhesive:

[0051] (a) Add 1.1moL epichlorohydrin into a three-necked flask equipped with a constant pressure dropping funnel and a reflux condenser, immerse in an ice-water bath, start stirring, and control the temperature within 0-5°C. After stirring for 10 minutes, Start to add 0.5 mol of diglycolamine slowly. After the addition, control the temperature at 0-5°C to continue the reaction for 2 hours, and then react at room temperature for 4 hours. After the reaction, remove excess epichlorohydrin by vacuum distillation; add 300 mL of ethanol Use as a solvent, then add 25% sodium hydroxide solution dropwise at a constant speed, and finish adding dropwise for 15 mi...

Embodiment 3

[0057] The synchronous belt of this embodiment is cast from rubber material and aramid fiber, and the rubber material includes the following components by weight:

[0058]

[0059] The preparation method of above-mentioned synchronous belt comprises the following steps:

[0060] (1) Preparation of adhesive:

[0061] (a) Add 1.1moL epichlorohydrin into a three-necked flask equipped with a constant pressure dropping funnel and a reflux condenser, immerse in an ice-water bath, start stirring, and control the temperature within 0-5°C. After stirring for 10 minutes, Start to add 0.5 mol of diglycolamine slowly. After the addition, control the temperature at 0-5°C to continue the reaction for 2 hours, and then react at room temperature for 4 hours. After the reaction, remove excess epichlorohydrin by vacuum distillation; add 300 mL of ethanol Use as a solvent, then add 25% sodium hydroxide solution dropwise at a constant speed, and finish adding dropwise for 15 minutes, then kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com