Wheel steel and heat treatment method and application thereof

A heat treatment method and wheel steel technology, which is applied in the field of rolling steel wheels for railway vehicles, can solve the problem of reducing the safety performance of medium and high carbon steel wheels, reducing the crack growth resistance inside the wheel, and the average value of the impact toughness of the web plate, etc. problems, to achieve the effect of promoting the refinement of pearlite sheets, improving the safety performance of the wheel, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

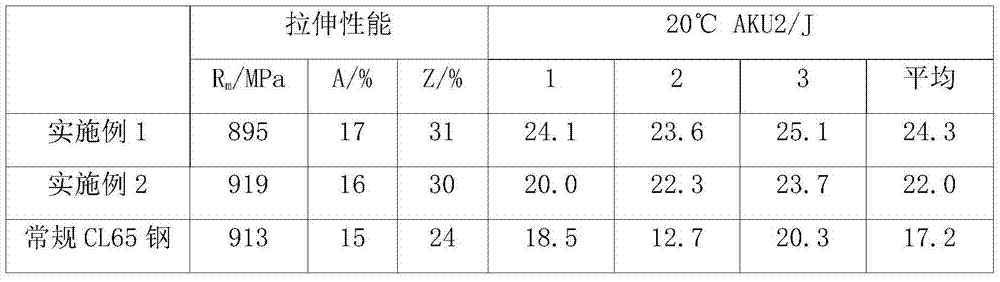

[0030] The molten steel whose chemical composition is shown in Example 1 in Table 1 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: after heating the furnace to 854°C and keeping it warm for 2.6 hours, the rim is sprayed with water to cool (the inner metal of the rim is cooled to below 550°C at a cooling rate of 2°C / s-5°C / s), When the temperature in the middle of the plate drops to 790°C, air-cool the web (so that the metal inside the web is cooled to below 732°C at a cooling rate of 4°C / s-7°C / s), then air-cool, and finally reheat to Temper at 497°C, holding time 4 hours and 30 minutes.

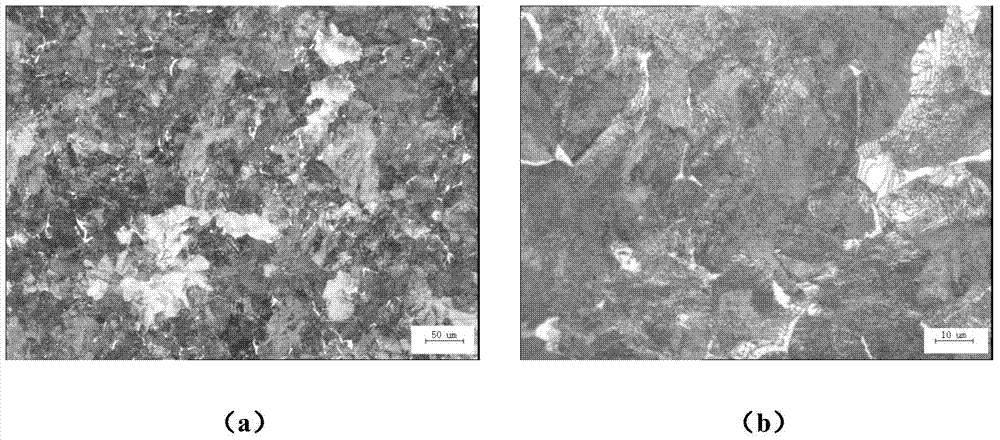

[0031] Such as figure 1 , 2 As shown, the microstructure of the wheel web prepared in this example is fine flaky pearlite + a small ...

Embodiment 2

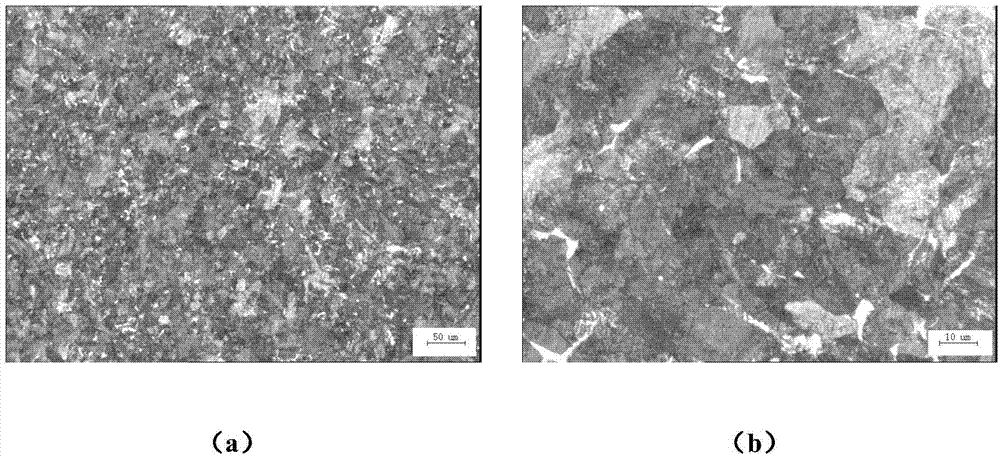

[0035] The molten steel whose chemical composition is shown in Example 2 of Table 1 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is: the molten steel whose chemical composition is as shown in Table 1 Example 2 is passed through the electric furnace steelmaking process, the LF furnace refining process, the RH vacuum treatment process, the round billet continuous casting process, the ingot cutting and rolling process, the heat treatment process, and the processing , The finished product inspection process is formed. The heat treatment process is as follows: after heating the furnace to 868°C and keeping it warm for 2.8 hours, the rim is sprayed with water to cool (the inner metal of the rim is cooled to below 550°C at a cooling rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com