Energy-efficient and environment-friendly liquid sodium silicate production technology and processing equipment

A technology of production technology and processing equipment, which is applied in the field of energy-saving and environment-friendly liquid sodium hydroxide production technology and processing equipment, and can solve the problems of high silicon content, ineffective water quenching effect, and difficulty in dissolving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

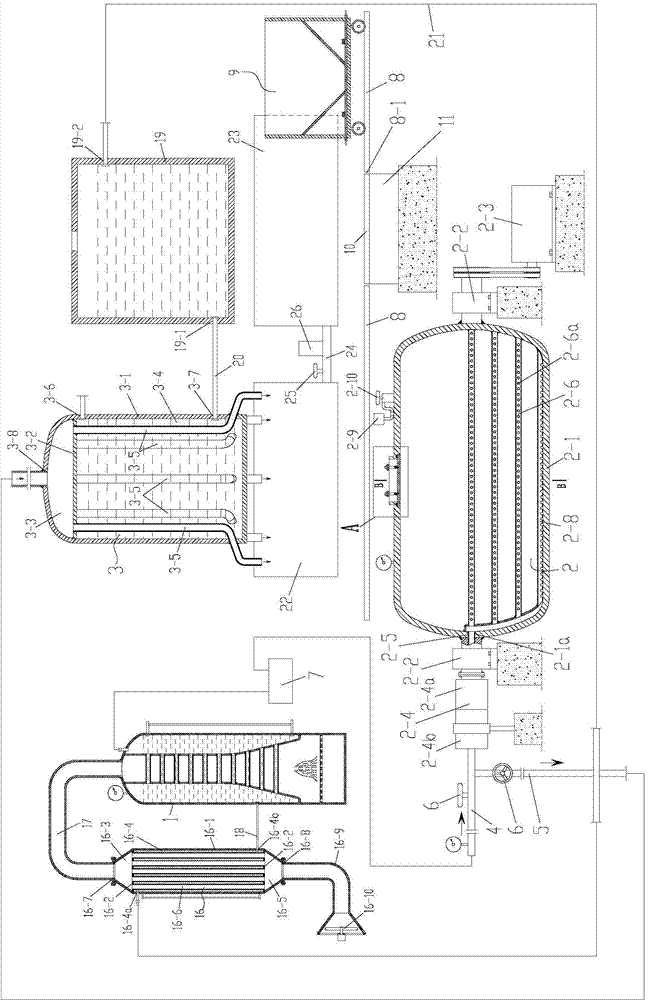

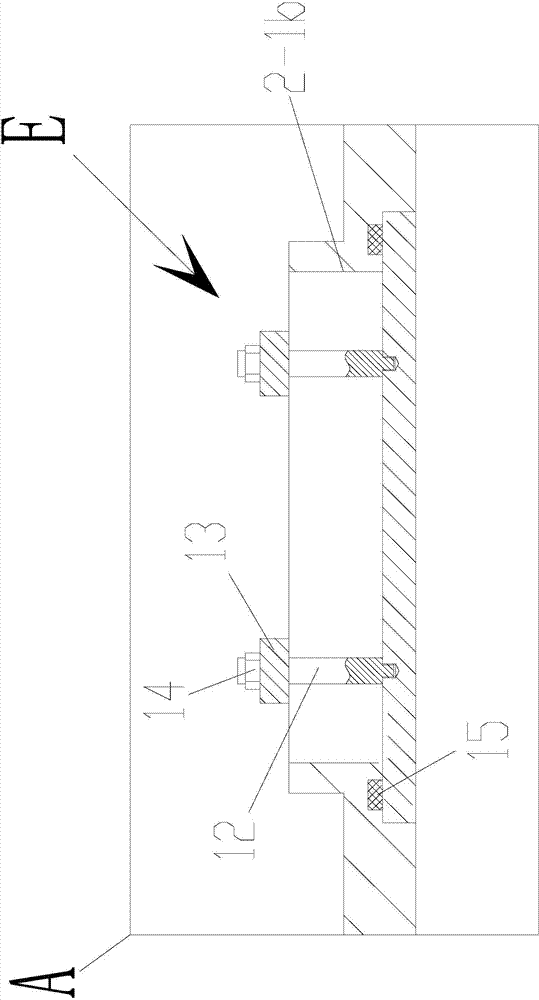

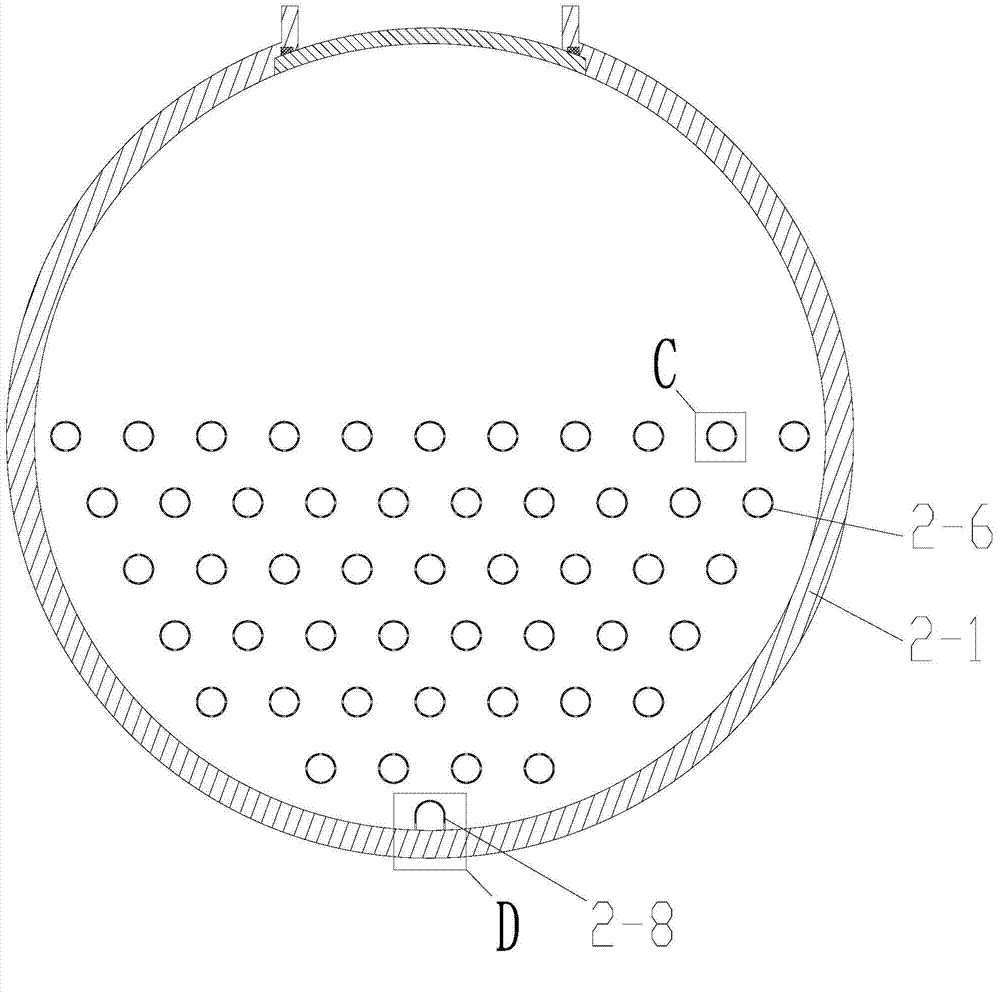

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] Referring to the accompanying drawings: the production process of this energy-saving and environment-friendly liquid sodium hydroxide, the specific steps are as follows:

[0036] A. charging: the solid sodium sodium granule is packed in the transport cart 9, weighs the transport cart 9, pushes the transport cart 9 to the top of the feed port 2-1b, opens the end cover 2-7, and puts the solid Sodium natron is loaded into airtight container 2-1, low modulus solid sodium natron with modulus less than 3 needs to add water in airtight container 2-1, high modulus solid sodium sodium with modulus greater than 3 does not need to be added in airtight container 2-1 Add water to the airtight container 2-1, and finally close the end cap 2-7;

[0037] B. Melting: When the melting modulus is less than 3 solid sodium sodium, close the valve switch three 2-10, and open the valve swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com