Impermeable and anti-cracking plastering mortar

A technology for plastering mortar and main material, applied in the field of building materials, can solve problems such as the performance to be further improved, and achieve the effects of improving workability, good anti-seepage performance, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

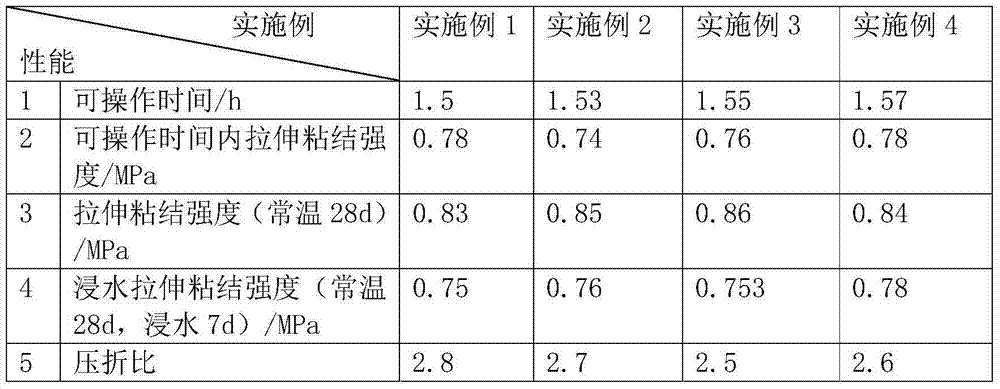

Examples

Embodiment 1

[0026] 1. Formula of anti-seepage and anti-crack plastering mortar:

[0027] The anti-seepage and anti-crack plaster mortar is composed of main materials and additives, among which:

[0028] The main material is composed of 40wt% cement (PO42.5 cement), 50wt% quartz sand 20-40 mesh and the remainder of fly ash;

[0029] Based on 1 ton of the main material, the dosages of the additives are: 2.5kg / ton of hydroxypropyl methylcellulose, 3.5kg / ton of wood fiber, 1kg / ton of polyvinyl alcohol, 25kg / ton of ash calcium, Redispersible latex powder 8kg / ton.

[0030] 2. Preparation method:

[0031] 1) Take each raw material according to the proportioning ratio, and set aside;

[0032] 2) Put the raw materials into the mixer in the order of cement, fly ash, quartz sand, hydroxypropyl methylcellulose, wood fiber, polyvinyl alcohol, lime calcium, and redispersible latex powder, and stir for 5 minutes to obtain the obtained The above-mentioned anti-seepage and anti-crack plastering mortar...

Embodiment 2

[0034] 1. Formula of anti-seepage and anti-crack plastering mortar:

[0035] The anti-seepage and anti-crack plaster mortar is composed of main materials and additives, among which:

[0036] The main body material is composed of 30wt% cement (PO42.5 cement), 55wt% quartz sand 30-40 mesh and the remainder of fly ash;

[0037] Based on 1 ton of the main material, the dosages of the additives are: 3kg / ton of hydroxypropyl methylcellulose, 3kg / ton of wood fiber, 1.5kg / ton of polyvinyl alcohol, 20kg / ton of ash calcium, Redisperse latex powder 6kg / ton.

[0038] 2. Preparation method:

[0039] 1) Take each raw material according to the proportioning ratio, and set aside;

[0040] 2) In the order of cement, fly ash, quartz sand, hydroxypropyl methylcellulose, wood fiber, polyvinyl alcohol, ash calcium, and redispersible latex powder, add the raw materials into the mixer and stir for 5 minutes to obtain The anti-seepage and anti-crack plastering mortar.

Embodiment 3

[0042] 1. Formula of anti-seepage and anti-crack plastering mortar:

[0043] The anti-seepage and anti-crack plaster mortar is composed of main materials and additives, among which:

[0044] The main material is composed of 40wt% cement (PO42.5 cement), 45wt% quartz sand 20-40 mesh and the remainder of fly ash;

[0045] Based on 1 ton of the main material, the dosages of the additives are: cellulose 2kg / ton, wood fiber 4kg / ton, polyvinyl alcohol 1kg / ton, ash calcium 30kg / ton, redispersible latex powder 9kg / ton Ton.

[0046] 2. Preparation method:

[0047] 1) take each raw material by proportioning, set aside;

[0048] 2) In the order of cement, fly ash, quartz sand, hydroxypropyl methylcellulose, wood fiber, polyvinyl alcohol, ash calcium, and redispersible latex powder, add the raw materials into the mixer and stir for 5 minutes to obtain The anti-seepage and anti-crack plastering mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com