Gypsum microspheres and low elastic modulus expansion cement system

A technology of gypsum microspheres and oil well cement, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of uneven distribution of pores, difficulties, difficult control of the gas expansion process, etc., and meet the needs of cementing engineering , Resist the effect of stress and strain, and ensure the effect of long-term safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 gypsum microspheres and preparation method thereof

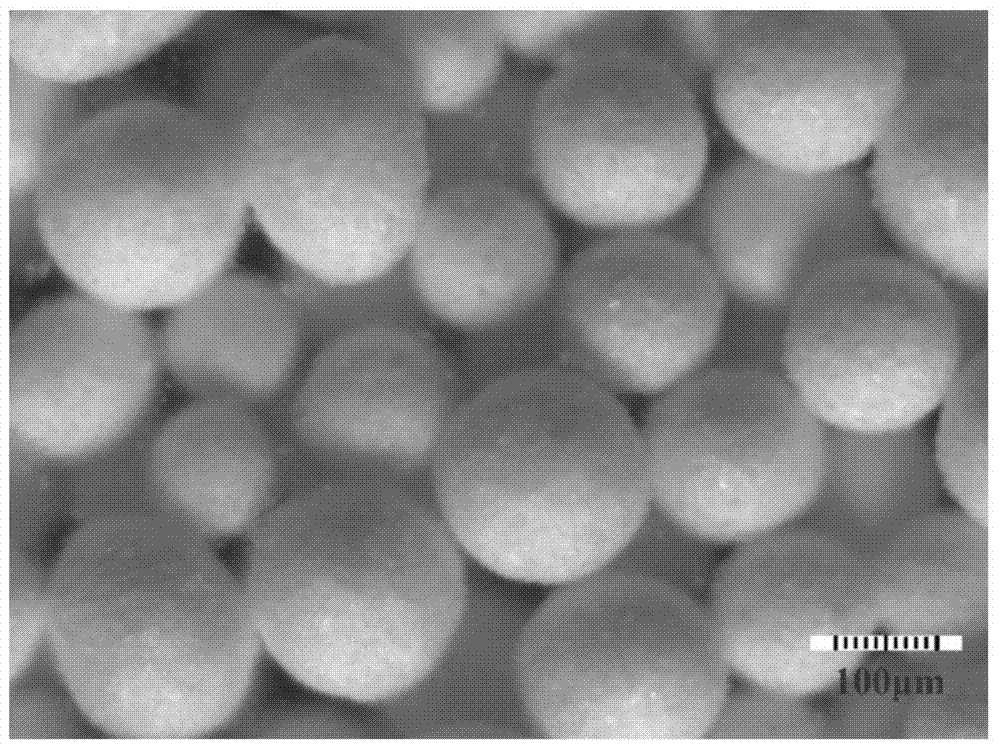

[0033] After mixing 6g of anhydrous gypsum (625 mesh) and 14g of α-type hemihydrate gypsum (625 mesh) evenly, add them into 16g of water, and stir evenly for 1.5min. Then, at room temperature, add the gypsum suspension into 200 g of corn oil, and stir while adding, at a stirring speed of 500 r / min. After adding the gypsum suspension into the corn oil, continue stirring for 2 hours. After the stirring is finished, filter out the gypsum microspheres, wash them, and dry them at room temperature to obtain gypsum microspheres with a particle size of about 100 μm, which are recorded as G1, such as figure 1 shown.

Embodiment 2

[0034] Embodiment 2 gypsum microspheres and preparation method thereof

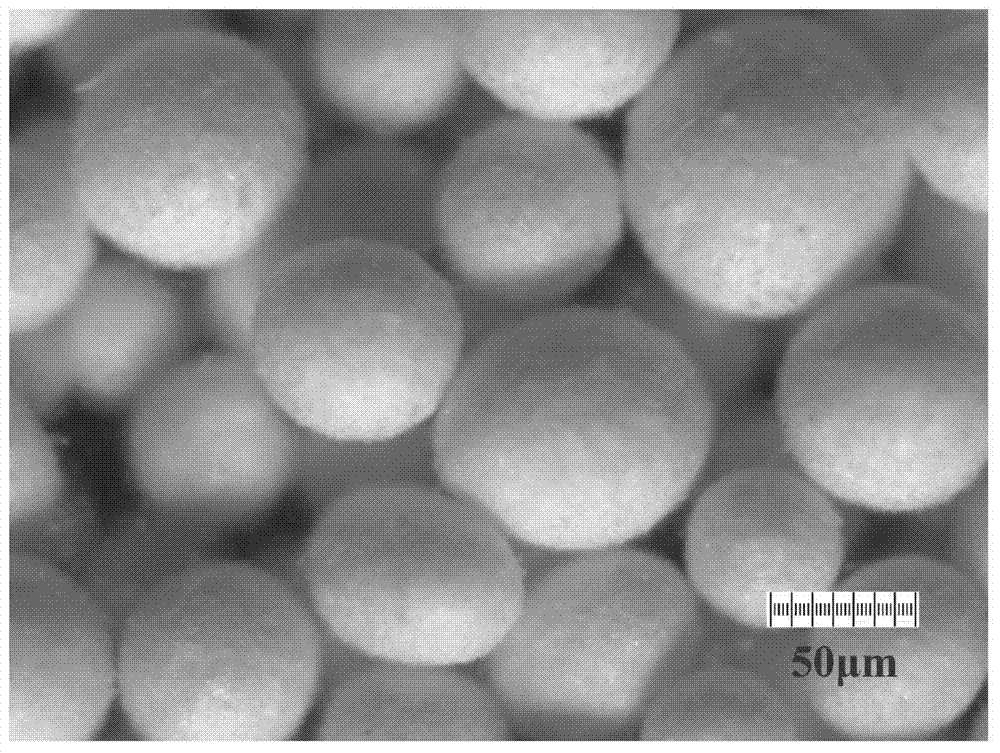

[0035] Mix 4g of anhydrous gypsum (800 mesh) and 16g of α-type hemihydrate gypsum (800 mesh) evenly, add them into 14g of water, and stir evenly for 2 minutes. Then, at room temperature, add the gypsum suspension into 300 g of soybean oil, and stir while adding, at a stirring rate of 600 r / min. After adding the gypsum suspension into the soybean oil, continue stirring for 2 hours. After the stirring is completed, filter out the gypsum microspheres, wash them, and dry them at room temperature to obtain gypsum microspheres with a particle size range of about 50-80 μm, which are recorded as G2, such as figure 2 shown.

Embodiment 3

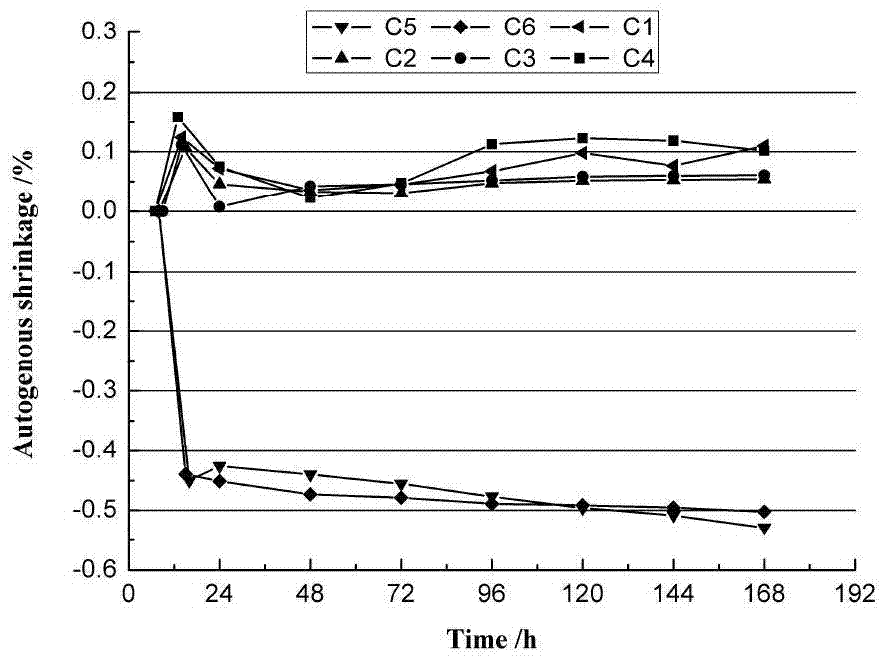

[0036] Example 3 Low elastic modulus expansion cement system

[0037] Cement slurry formula: 100 parts of G grade oil well cement + 25 parts of gypsum microspheres (G1) + 8 parts of micro silicon + 65 parts of water. The resulting cement stone sample is denoted as C1.

[0038] Preparation method: dry-mix oil well cement, gypsum microspheres and micro-silicon, and then prepare cement slurry with the dry-mixed system and water according to GB19139-2003 oil well cement test method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com