A kind of preparation method of high-capacity lithium cobalt oxide cathode material

A cathode material, lithium cobalt oxide technology, applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve the problem that lithium cobalt oxide cannot meet the requirements, etc., and achieves the benefits of solution exchange and ion transfer, low production costs, and reduced production costs. The effect of electrode polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

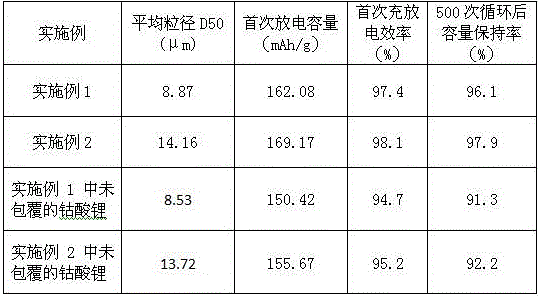

Embodiment 1

[0023] Take 5g of lithium cobalt oxide positive electrode material, the average particle size D50 is 8.53 μm, and perform electroless nickel plating treatment. The process of electroless nickel plating is:

[0024] 1. Add the above-mentioned lithium cobaltate into the alcohol aqueous solution with a volume ratio of alcohol to water of 1:1 and a total volume of 1L. The temperature is 25° C., the stirring speed is 200 rpm, and the ultrasonic vibration is performed at a frequency of 30 kHz for 5 min.

[0025] The lithium cobaltate was centrifuged and washed several times with deionized water.

[0026] 2. Add the cleaned lithium cobaltate into a solution whose composition is stannous chloride (SnCl2 2H2O) 4g / L, 37% HCl 4mL / L, OP-101mL / L, solvent is deionized water, and the volume is 1L . The temperature is 25°C, the stirring speed is 200 revolutions per minute, and the time is 2 minutes.

[0027] Lithium cobaltate was centrifuged and washed with deionized water to pH 7.

[002...

Embodiment 2

[0035] Take 20g of lithium cobalt oxide positive electrode material, the average particle size D50 is 13.72 μm, and perform electroless nickel plating treatment. The process of electroless nickel plating is:

[0036] 1. Add the above-mentioned lithium cobaltate into the alcohol aqueous solution with a volume ratio of alcohol to water of 1:2 and a total volume of 1L. The temperature is 25° C., the stirring speed is 200 rpm, and the ultrasonic vibration is performed at a frequency of 35 kHz for 8 min.

[0037] The lithium cobaltate was centrifuged and washed several times with deionized water.

[0038] 2. Add the cleaned lithium cobaltate to the composition of stannous chloride (SnCl2 2H2O) 7g / L, 37% HCl 5mL / L, 0.5mL / L each of sucrose ester and OP-10, and the solvent is deionized water. in a solution with a volume of 1 L. The temperature is 25° C., the stirring speed is 400 revolutions per minute, and the time is 2 minutes.

[0039] Lithium cobaltate was centrifuged and washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com