Control circuit and control method of vehicle-mounted charger DC-DC system

A technology of DC-DC and on-board charger, which is applied in the direction of battery circuit devices, current collectors, circuit devices, etc., can solve the problems of charging system safety impact, high inductance current, damage to chips, etc., to achieve easy process implementation and reduce chip costs , The effect of simple circuit function principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

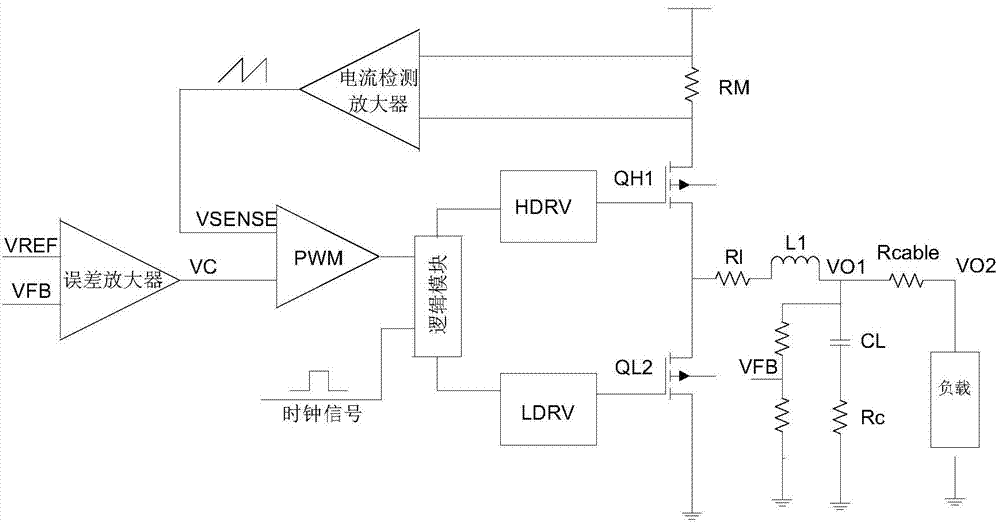

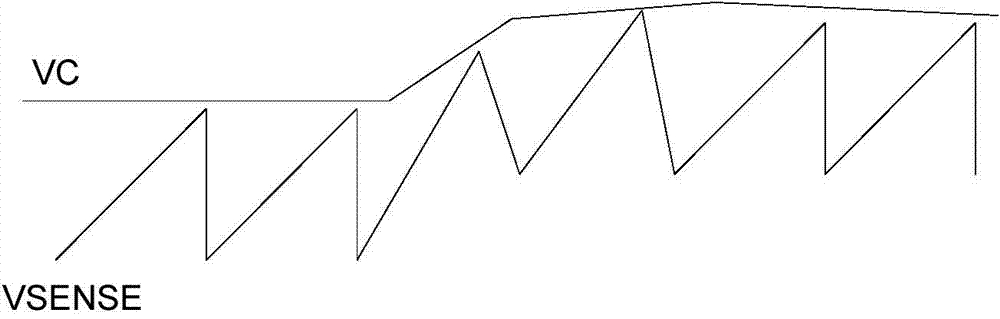

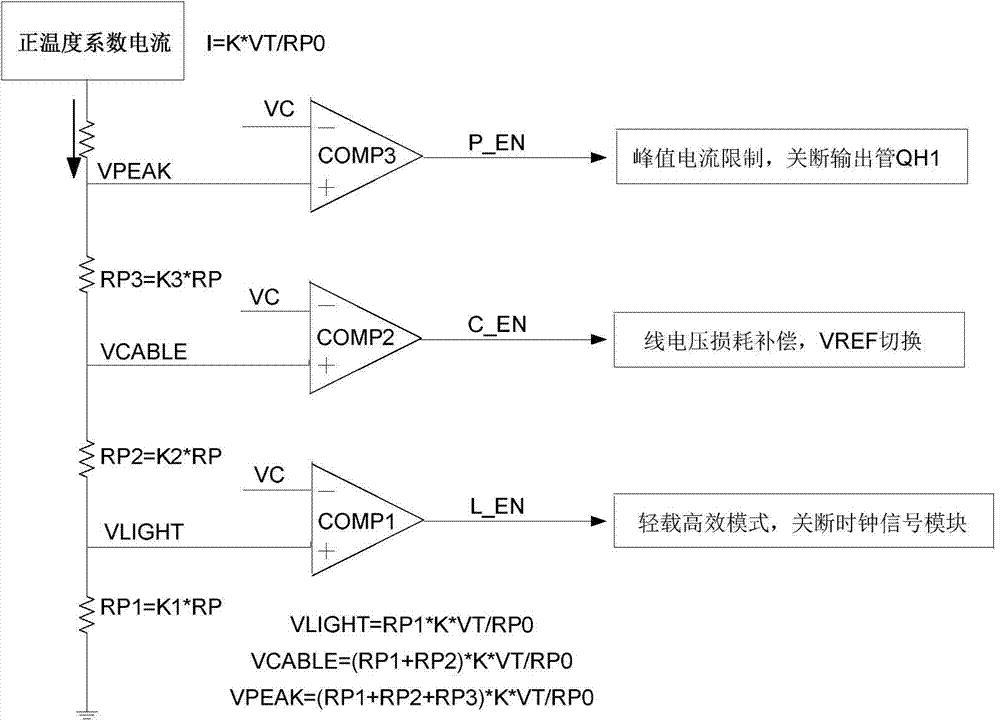

[0024] Such as figure 1 As shown, the current sense amplifier detects the voltage drop of the metal parasitic resistance RM on the power tube path and amplifies it, and the output of the current sense amplifier is the amplified voltage signal VSENSE, which has the same temperature coefficient as the metal resistance RM, about 3000ppm , this VSENSE signal will be compared with the output signal VC of the internal error amplifier through the PWM comparator to control the change of the output duty cycle. When VSENSE reaches VC in each cycle, the power tube will be turned off and wait for the next clock signal to come. Turn on the power tube, and so on. figure 2 The curve shows the relationship between VSENSE and VC signal, so that the peak value of VSENSE signal in each cycle will be equal to VC, so the VC signal will have the same variation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com