Slurry feeding type metal part material increase manufacturing method and device

A metal parts and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of high requirements for grouting equipment, poor adaptability of wire material position, low powder utilization rate, etc., and achieve good grout feeding accuracy and controllability, The effect of fast adjustment response speed and stable slurry feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

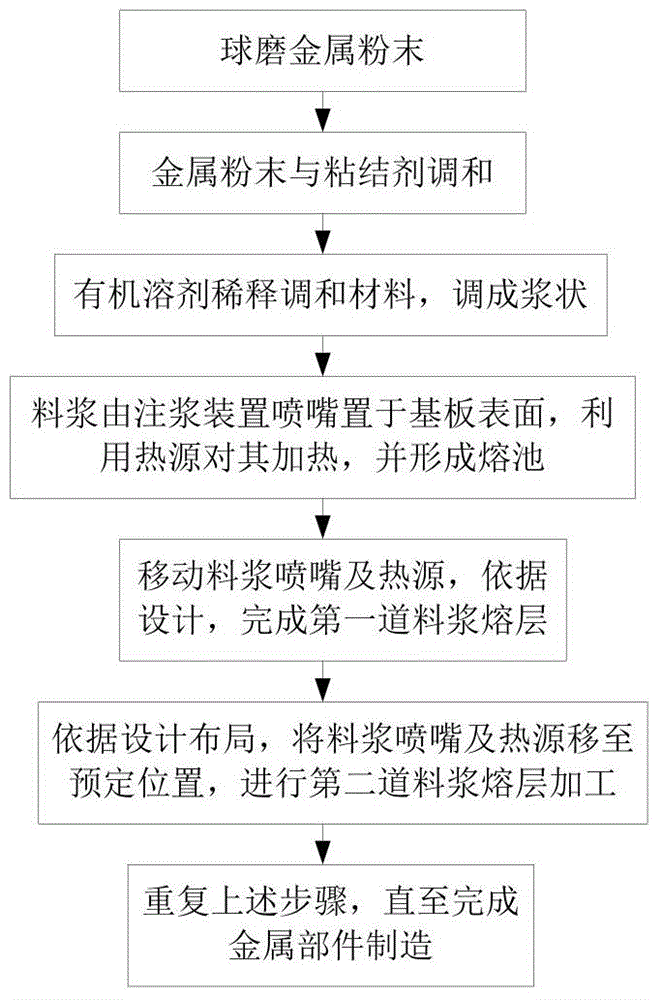

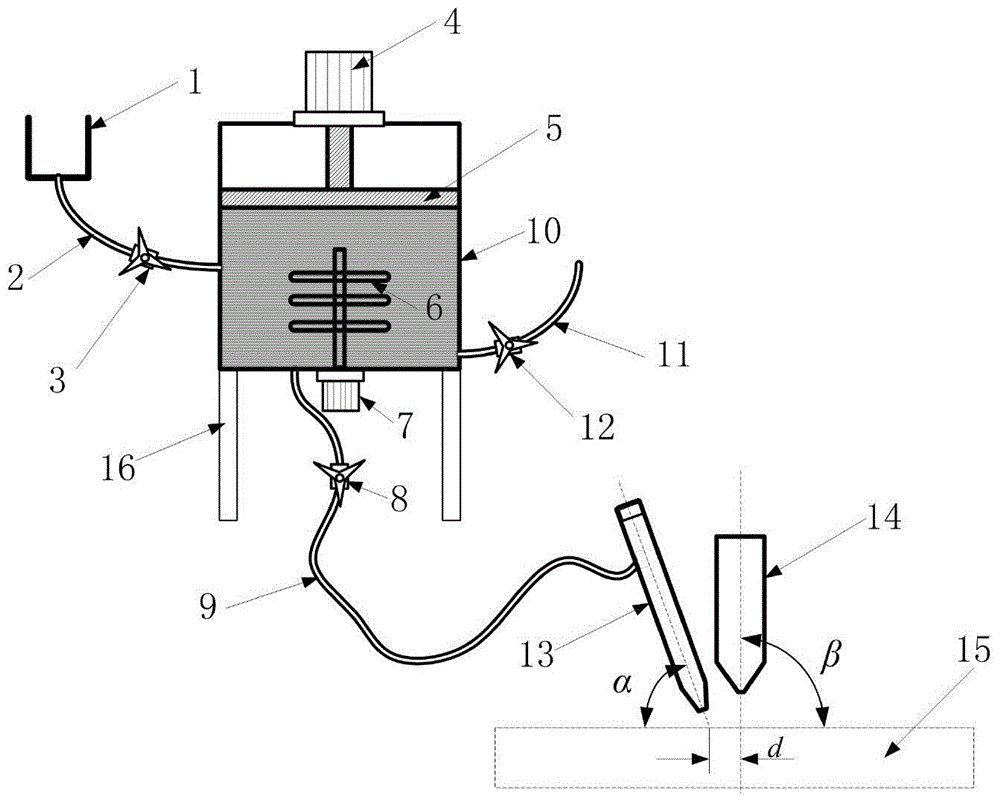

[0042] Such as figure 1 Shown here is a method for additive manufacturing of metal parts with slurry feeding of the present invention. The IPG fiber laser heat source is used to place the laser welding gun and slurry nozzle on the welding ABB robot arm. The slurry nozzle is in front and the laser heat source is in Rear. The specific steps are:

[0043] (1) First, ball mill the required metal powder, preferably high-energy ball milling, and the particle size of the metal powder after ball milling is between 100 nm and 100 μm;

[0044] (2). The metal powder and the binder are blended according to the mass ratio of 20:1 to 1:1. Choose the following combination of binder: polyvinyl butyral resin (mass fraction 1%-20%), polyethylene glycol (mass fraction 1%-20%), the balance is alcohol;

[0045] (3). Then the material obtained in step (2) and the organic solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com