Method and system for nitrogen and phosphorus removal via water treatment plant waste sludge (WTRs) reinforced tidal-flow reactor

A technology of nitrogen and phosphorus removal and tidal flow, applied in the field of environmental engineering, can solve the problem of low nitrogen and phosphorus removal rate, and achieve the effect of strengthening the action of microorganisms, improving the bacterial habitat and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

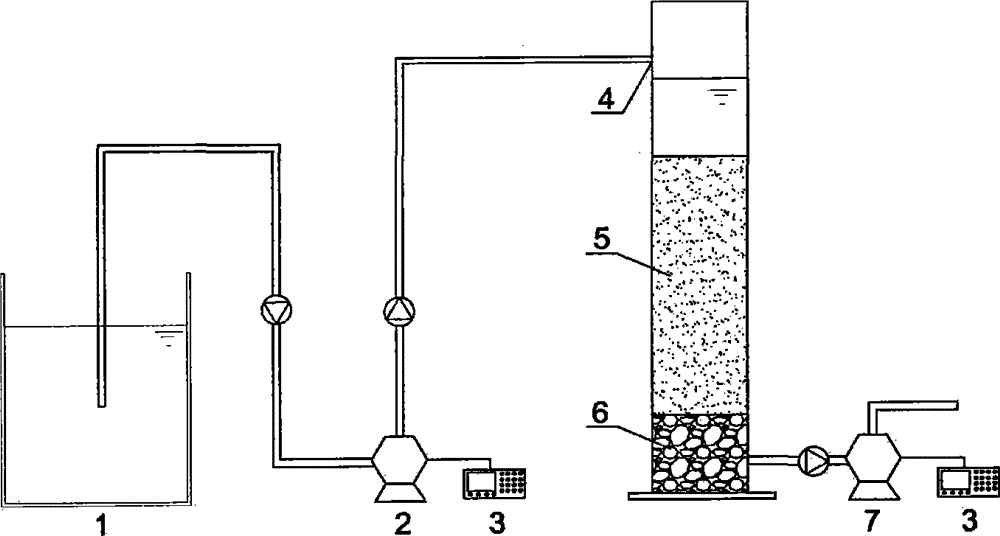

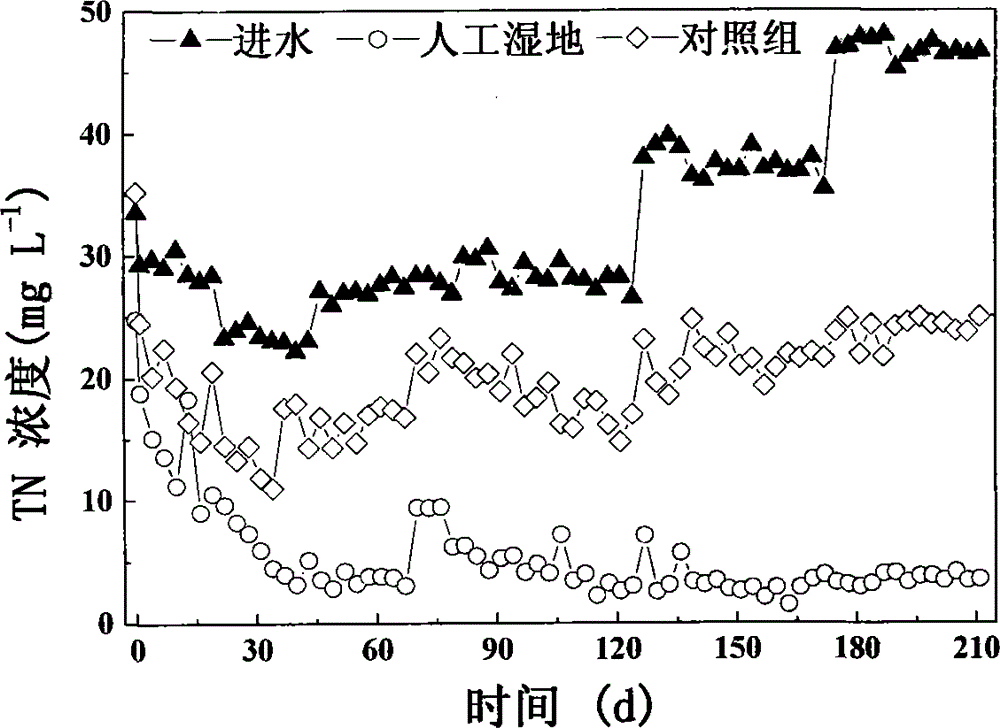

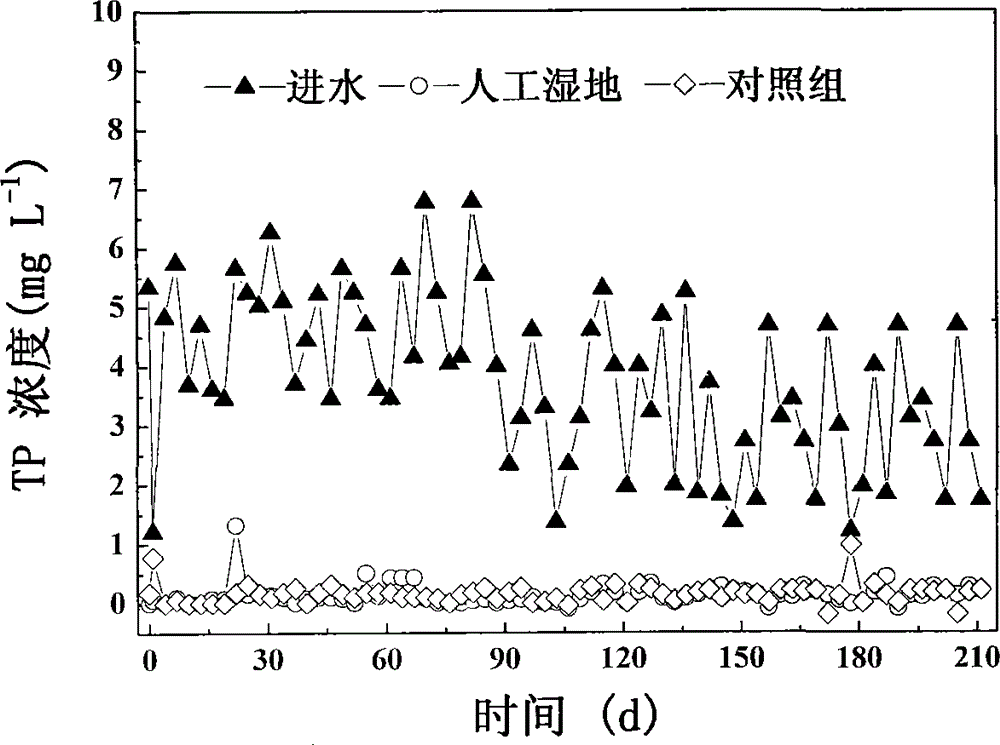

[0026] Example 1: Using waste sludge (WTRs) from a water purification plant in Beijing as raw material, the content of iron and aluminum in the waste sludge is 150 and 100mgg respectively -1 . The waste mud of the water purification plant is made into 1-3cm balls and dried naturally. The tidal flow reactor is a plexiglass cylinder with an inner diameter of 10 cm and a height of 100 cm. The bottom is laid with 10 cm high pebbles (6-10 mm) and 5 cm high quartz sand (2-6 mm). The prepared WTRs of about 1.7 kg are filled to a height of 75cm. Take 1 kg of sediment from a eutrophic lake in North China and add it to the tidal flow reactor. In addition, the second column enriched the sediment without WTRs and used it as a control. The operation cycle is 1 day, water inflow for 4 minutes, reaction for 21h53min, emptying for 3min, and idle for 2h. The daily processing capacity is 2.5L. Influent PO 43+ , NO 2 - and NO 3 - The average concentration is 3.5mg / L, 10mg / L and 5mg / L r...

example 2

[0027] Example 2: Also use waste mud (WTRs) from a water purification plant in Beijing as raw materials. The tidal flow reactor is a plexiglass cylinder with an inner diameter of 10 cm and a height of 100 cm. The bottom is laid with 10 cm high pebbles (6-10 mm) and 5 cm high quartz sand (2-6 mm). The prepared WTRs of about 1.7 kg are filled to a height of 75cm. Take 800g of sediment from a river polluted with high ammonia nitrogen in North China and add it to the tidal flow reactor. In addition, the second column enriched the sediment without WTRs and used it as a control. The operation cycle is 1 day, water inflow for 4 minutes, reaction for 21h53min, emptying for 3min, and idle for 2h. The daily processing capacity is 2.5L. Influent PO 4 3+ , NH 4 + , NO 2 - and NO 3 - The average concentrations were 3.5mg / L, 10mg / L, 10mg / L and 5mg / L, and PO in water was measured every 3 days 4 3+ , NH 4 + , NO 2 - and NO 3 - concentration. After 212 days of operation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com