Method for synchronously recycling heavy metal in garbage leachate and acid mine drainage waste

A technology for landfill leachate and acid mines, applied in chemical instruments and methods, improvement of process efficiency, multi-stage water/sewage treatment, etc., can solve problems such as no simultaneous removal of heavy metal ions, and achieve good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment tests the optimum selection of landfill leachate and acid mine drainage mixing ratio according to the following steps:

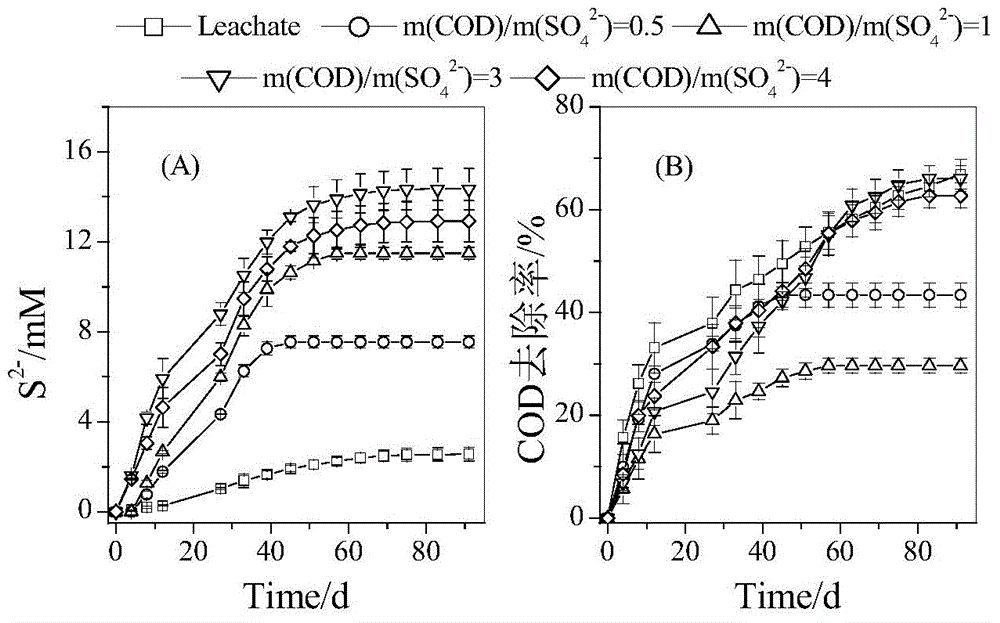

[0023] Take an appropriate amount of landfill leachate and a pyrite acid mine drainage, respectively according to m(COD) / m(SO 4 2- ) ≈ 0.5, 1, 3, and 4 to form a mixed solution. The total amount of the mixed solution is 500mL. At the same time, the pure landfill leachate Leachate is used as a comparison. Suitable m(COD) / m(SO 4 2- ) ratio, the experimental results are as figure 1 shown. Due to the low sulfate concentration contained in the landfill leachate, the S produced 2- Also less, less than 3mmol / L; in the mixed solution of the 4 groups, m(COD) / m(SO 4 2- ) in response groups with higher values of S 2- More and produce S in the early stage of reaction 2- The rate is faster. m(COD) / m(SO 4 2- ) is 3 in the experimental group S 2- The concentration is slightly higher than m(COD) / m(SO 4 2- ) is the experimental ...

Embodiment 2

[0025] a. According to m(COD) / m(SO 4 2- ) ≈ 3 mix the landfill leachate on a tailings pond and the drainage of a pyrite acid mine nearby, adjust the pH to 7.5 with 1mol / L NaOH solution to obtain a mixed solution, and then place it in 4L for anaerobic reaction device. The main components and contents of the mixture are shown in Table 1.

[0026] Table 1m(COD) / m(SO 4 2- ) ≈ 3, the main components and contents of landfill leachate and a pyrite acid mine drainage mixture

[0027]

[0028] b. Charge argon into the anaerobic reactor operated in step a to replace the air in the reactor, so that the reaction environment remains anaerobic.

[0029] c. Control the temperature of the anaerobic reactor in step b at 30-35°C, add the mixed solution as influent into the anaerobic reactor, control the hydraulic retention time of the reactor at the initial stage of 30 days, and continue to run until COD The removal rate reaches 90%, and the sulfate removal rate is not less than 80%, m...

Embodiment 3

[0038] The benefit description of the inventive method applied in actual sewage treatment plant:

[0039] A landfill site in Ma'anshan, Anhui Province is located on a tailings pond, with a daily output of 150 tons of landfill leachate, and a nearby pyrite mine produces about 80 tons of acidic mine drainage on a daily basis. An anaerobic sewage treatment pool with a working volume of 30,000 cubic meters is built in the landfill.

[0040] Water quality characteristics of landfill leachate and acid mine drainage: COD of landfill leachate is about 50000mg / L, NH 4 + -N 2000mg / L; in acidic mine drainage, sulfate radical 29975mg / L, pH 2.75, COD 429.6mg / L, total iron 133mg / L. According to m(COD) / m(SO 4 2- ) ≈ 3 Mix landfill leachate and acid mine drainage, and then process a total of 230 tons of mixed solution per day. Based on the calculation that the hydraulic retention time of the anaerobic sewage tank is 20 days, 90 tons of anaerobic sludge will be discharged every 30 days. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com