Electron transport layer material and perovskite solar cell

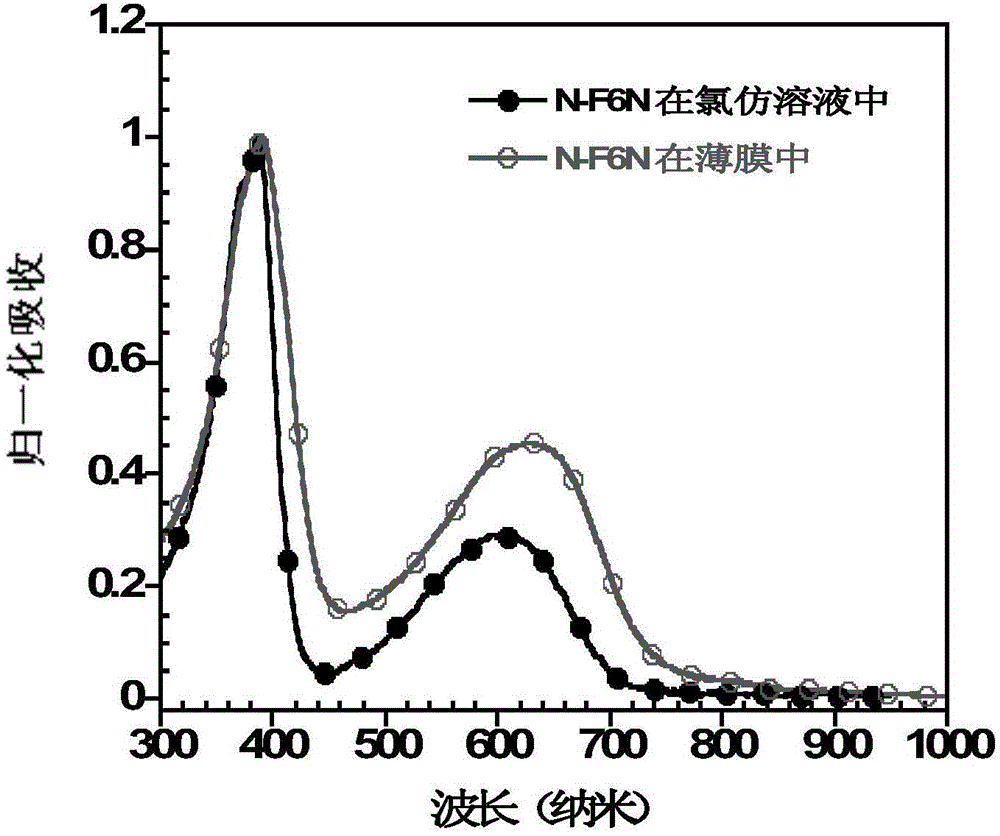

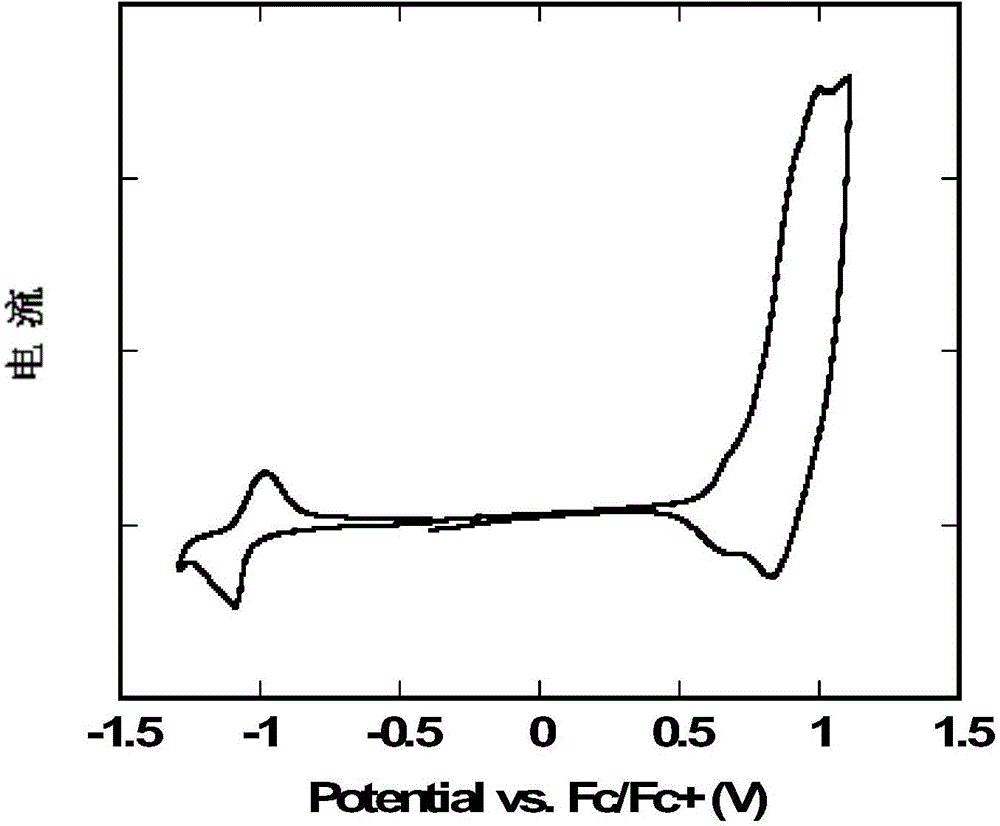

An electron transport layer and hole transport layer technology, applied in the field of perovskite solar cells, can solve the problems of being unsuitable for industrialized large-scale production, complex synthesis process of fullerene derivatives, difficult purification, etc. The effect of transmission capacity, wide absorption, and high absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Preparation of poly{2,7-[N,N'-bis(2-ethylhexane)-1,7-dithiophene-perylenetetracarboxylic diimide]-co-2,7-[9,9 '-Di(6-N,N-diethylamino-hexyl)fluorene]} (referred to as NDIT-F6N)

[0036] The synthetic route is as follows:

[0037]

[0038] (1) Monomer 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaboryl)-9,9'-bis(6-N,N- Diethylamino-hexyl)fluorene] was prepared according to the method disclosed in the literature (Adv. Mater., 2011, 23, 1665). Monomer 2,7-dibromo-N,N'-bis(2-ethylhexane)-1,7-dithiophene-perylenetetracarboxylic acid diimide is according to literature (Chem.Mater.,2011, 23,4563) disclosed method preparation.

[0039] (2) The monomer 2,7-dibromo-N,N'-bis(2-ethylhexane)-1,7-dithiophene-perylenetetracarboxylic acid diimide (0.25mmol), 2, 7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborinyl)-9,9'-bis(6-N,N-diethylamino-hexyl) ) fluorene] (0.25mmol) and 9mg three (dibenzylidene acetone) dipalladium and 23mg three (o-methylphenyl) phosphine catalysts are dissolved in the m...

Embodiment 2

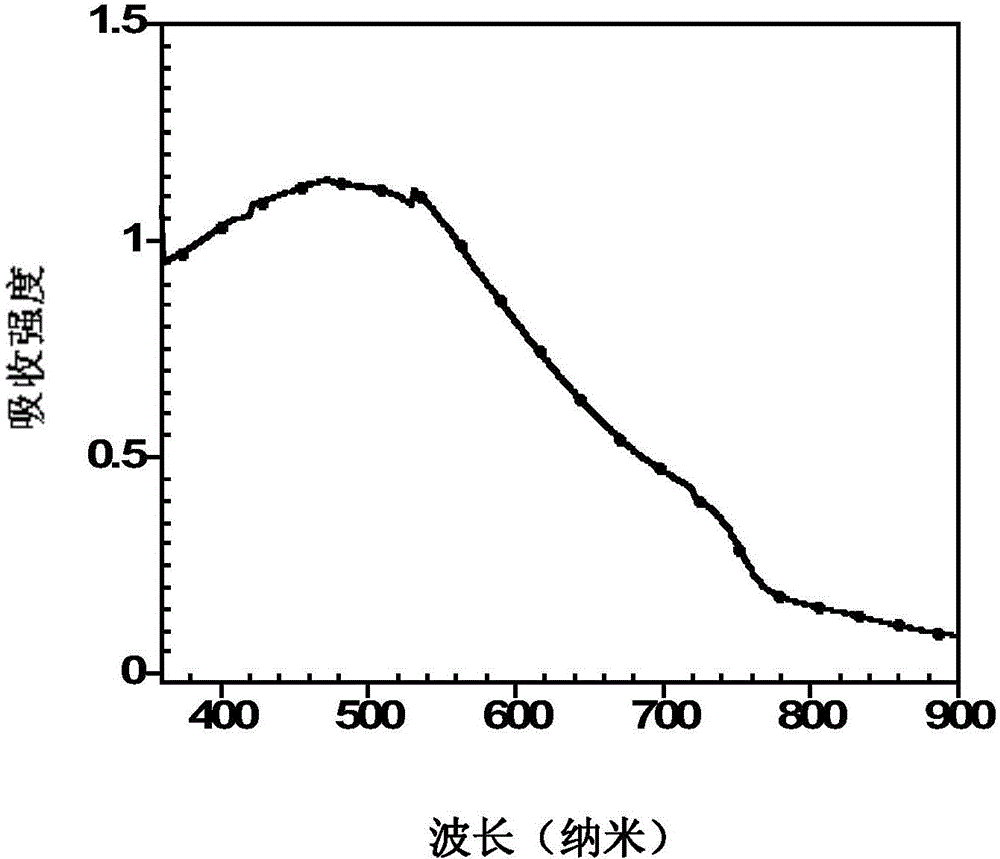

[0043] Preparation of photoactive layer materials:

[0044] The CH of the compound I 3 NH 3 The synthesis of I was prepared according to the method disclosed in the literature (J.Am.Chem.Soc.2012, 134, 17396). CH 3 NH 3 PB 3-x Cl x The synthesis of CH 3 NH 3 I, PbI 2 and PbCl 2 Co-dissolved in DMF (N, N-dimethylformamide) or other organic solvents, the specific details are as follows:

[0045] Take CH 3 NH 3 I, PbI 2 and PbCl 2 (The ratio is 4:1:1) was blended and dissolved in 1mL DMF to prepare a solution with a mass fraction of 40%, heated to 60°C, and stirred for 12 hours to obtain a photoactive layer material precursor solution.

[0046] Compound I (CH 3 NH 3 I) and compound II (PbI 2 :PbCl 2 =1:1) mixed at a ratio of 2:1, dissolved in an organic solvent, and then formed a photoactive layer by spin coating.

Embodiment 3

[0048] Preparation of organic-inorganic planar heterojunction solar cells:

[0049] Some ITO conductive glass, the square resistance is about 20 ohms / square, and the specification is 15 mm x 15 mm square. Use acetone, micron-scale semiconductor special detergent, deionized water, and isopropanol to ultrasonically clean for more than half an hour, and place in a constant temperature oven for later use. Before use, ITO glass slides were treated in oxygen plasma for 4 min. PEDOT:PSS (polyethylene dioxythiophene) aqueous dispersion (purchased from Bayer, Clevios P VP AI4083) was used as the hole transport layer, and was spin-coated on ITO at high speed with a homogenizer (KW-4A), and the film thickness About 40 nanometers is better, and the thickness is determined by the concentration of the solution and the rotational speed. It is measured and monitored with a surface profiler (Alpha-Tencor-500 type of Tritek Company). After film formation, heat at 150°C for 20 minutes in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com