Between-closed-pore-and-open-pore EVA (Ethylene-Vinyl Acetate copolymer) foamed shoe material and manufacturing method thereof

A manufacturing method and closed-cell technology, applied in footwear, shoe soles, footwear, etc., can solve the problems of easy shrinkage of EVA foam shoe materials and no related reports, and achieve enhanced impact resistance, excellent physical properties, and overcoming Thick and wrinkled skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. The composition of raw materials by mass percentage is as follows:

[0047] Ethylene-vinyl acetate copolymer EVA7470M: 45%;

[0048] Ethylene-vinyl acetate copolymer EVA7350M: 25%;

[0049] Ethylene-octene copolymer POE8150: 15%;

[0050] EPDM3745P: 6%;

[0051] Stearic acid: 0.4%;

[0054] Dicumyl peroxide: 0.6%;

[0055] Mixed blowing agent: 3%;

[0056] Masterbatch: 3%.

[0057] 2. the manufacture method of the EVA foam shoe material between described open cell and closed cell, comprises the following steps:

[0058] 1) Pound material

[0059] Weigh the raw materials according to the designed formula, weigh the dicumyl peroxide and the mixed blowing agent separately, mix the two together, and mix the rest together;

[0060] 2) Banbury

[0061] Pour the prepared raw materials into a 75L internal mixer except for dicumyl peroxide and foaming agent, and start the internal mixer to mix the materials evenly....

Embodiment 2

[0074] Embodiment 2: adjust the consumption of EVA7470M, EVA7350M, POE8150 on the basis of embodiment 1, its raw material formula is as follows:

[0075] Ethylene-vinyl acetate copolymer EVA7470M: 53%;

[0076] Ethylene-vinyl acetate copolymer EVA7350M: 22%;

[0077] Ethylene-octene copolymer POE8150: 10%;

[0078] EPDM3745P: 6%;

[0079] Stearic acid: 0.4%;

[0081] Zinc oxide: 1%;

[0082] Dicumyl peroxide: 0.6%;

[0083] Mixed blowing agent: 3%;

[0084] Masterbatch: 3%.

Embodiment 3

[0085] Embodiment 3: On the basis of embodiment 2, continue to adjust the consumption of EVA7470M, EVA7350M, POE8150, EPDM3745P, make it control within the set dosage range, its raw material formula is as follows;

[0086] Ethylene-vinyl acetate copolymer EVA7470M: 50%;

[0087] Ethylene-vinyl acetate copolymer EVA7350M: 25%;

[0088] Ethylene-octene copolymer POE8150: 11%;

[0089] EPDM3745P: 5%;

[0090] Stearic acid: 0.4%;

[0091] Zinc stearate: 1%;

[0092] Zinc oxide: 1%;

[0093] Dicumyl peroxide: 0.6%;

[0094] Mixed blowing agent: 3%;

[0095] Masterbatch: 3%.

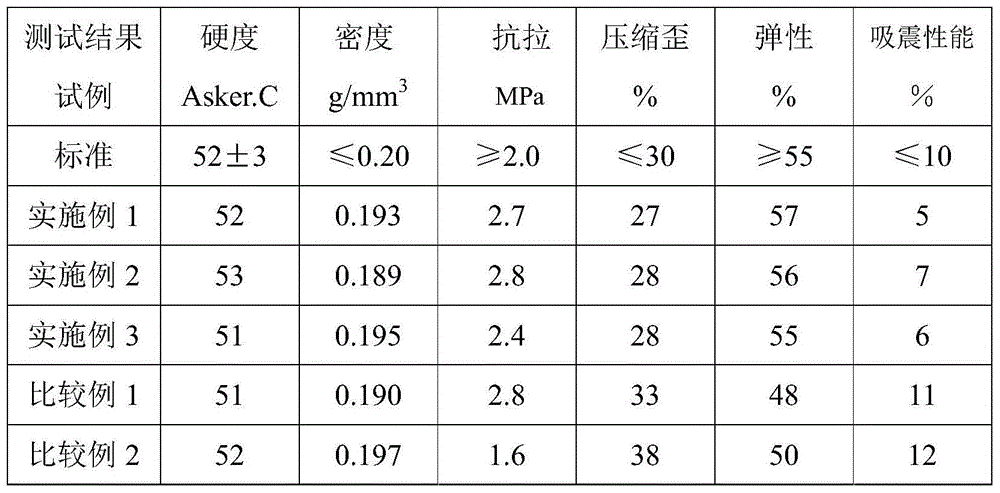

[0096] In order to better illustrate the research results, the use of the blowing agent in the formula does not use a mixed blowing agent. Comparative example 1 uses the azo blowing agent instead of the mixed blowing agent on the basis of Example 1 ), comparative example 2 is that on the basis of embodiment 2, the mixed foaming agent is changed to an open-cell foaming agent (H), and comparative example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com