Zirconium chelate-modified compound alkali soluble emulsion as well as high-resolubility waterborne ink prepared from emulsion and method

A zirconium chelate, water-based ink technology, applied in inks, applications, household appliances, etc., can solve the problems of unsatisfactory water resistance, poor resolubility of water-based inks, etc., to achieve water resistance, improve water resistance and solid content. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

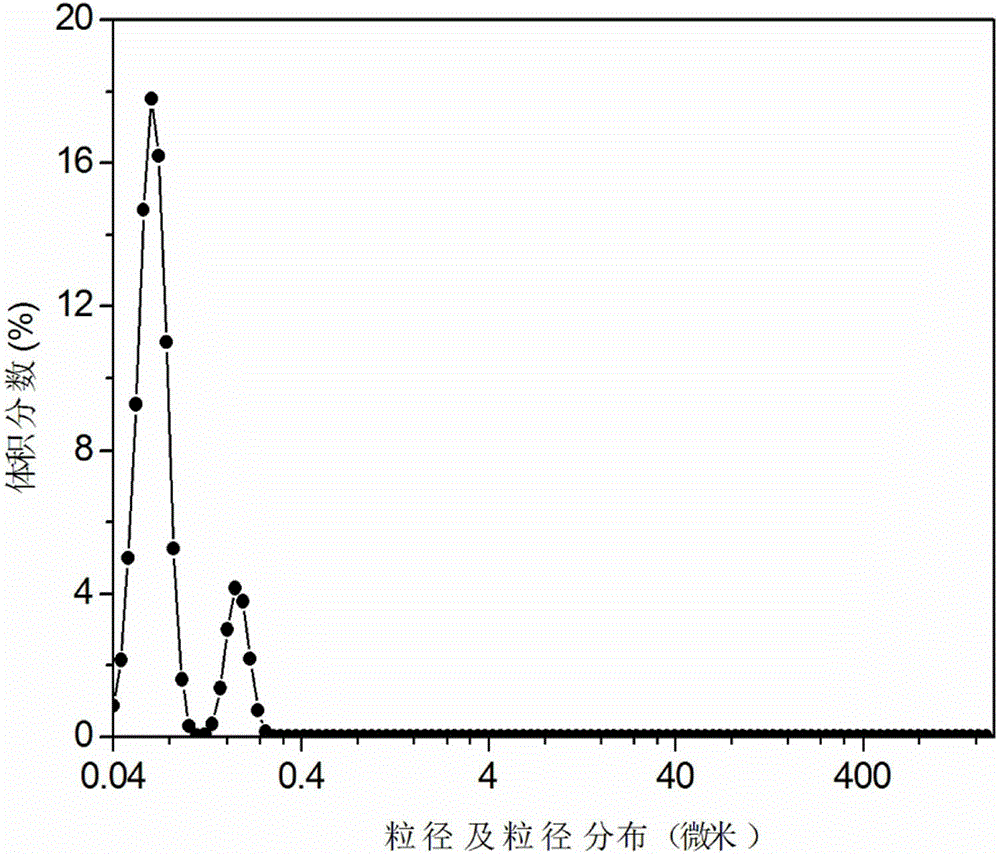

Image

Examples

Embodiment 1

[0032] A kind of composite alkali-soluble emulsion modified by zirconium chelate, comprising the following raw materials by weight:

[0033] Diphenylmethane diisocyanate (MDI): 15 parts, triethanolamine chelated zirconium isopropoxide (Zr(TEA) 2 (OR) 2 ): 0.02 parts, acrylic acid (AA) 16 parts, polyvinyl alcohol (PVA): 0.25 parts, methyl methacrylate (MMA): 22 parts, butyl acrylate (BA): 5 parts, styrene (St): 5 parts, propylene oxide: 4.5 parts, butyl methacrylate (BMA): 4.5 parts, sodium hydroxide (NaOH): 8 parts, dibenzoyl peroxide (BPO): 0.3 parts, alkylphenol polyoxygen Vinyl ether (OP-10): 2 parts, Sodium dodecyl sulfate (SDS): 1.0 parts, Deionized water: 20 parts

Embodiment 2

[0035] A kind of composite alkali-soluble emulsion modified by zirconium chelate, comprising the following raw materials by weight:

[0036] Diphenylmethane diisocyanate (MDI): 25 parts, triethanolamine chelated zirconium isopropoxide (Zr(TEA) 2 (OR) 2 ): 0.04 parts, acrylic acid (AA) 19 parts, polyvinyl alcohol (PVA): 0.45 parts, methyl methacrylate (MMA): 26 parts, butyl acrylate (BA): 8 parts, styrene (St): 7 parts, propylene oxide: 7.5 parts, butyl methacrylate (BMA): 6.7 parts, sodium hydroxide (NaOH): 12 parts, dibenzoyl peroxide (BPO): 0.5 parts, alkylphenol polyoxygen Vinyl ether (OP-10): 4 parts, Sodium dodecyl sulfate (SDS): 2.0 parts, Deionized water: 30 parts

Embodiment 3

[0038] A kind of composite alkali-soluble emulsion modified by zirconium chelate, comprising the following raw materials by weight:

[0039] Diphenylmethane diisocyanate (MDI): 20 parts, triethanolamine chelated zirconium isopropoxide (Zr(TEA) 2 (OR) 2 ): 0.03 parts, acrylic acid (AA) 18.14 parts, polyvinyl alcohol (PVA): 0.36 parts, methyl methacrylate (MMA): 24.19 parts, butyl acrylate (BA): 6.05 parts, styrene (St): 6.05 parts, propylene oxide: 5 parts, butyl methacrylate (BMA): 5.26 parts, sodium hydroxide (NaOH): 10 parts, dibenzoyl peroxide (BPO): 0.42 parts, alkylphenol polyoxygen Ethylene (OP-10): 3 parts, Sodium dodecyl sulfate (SDS): 1.50 parts, Deionized water: 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com