Novel fuel gas baking oven for vinegar brewing, fire-curing and fermenting and vinegar brewing, fire-curing and fermenting method thereof

A gas-fired roasting and roasting furnace technology, which is applied in the preparation of vinegar and other directions, can solve the problems of uneven temperature, difficult control of roasting (smoked roasting) process, unstable roasting temperature of vinegar fermented grains, etc. The effect of promoting large-scale development of enterprises and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

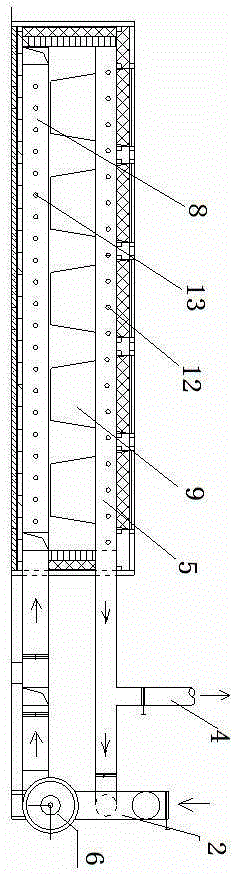

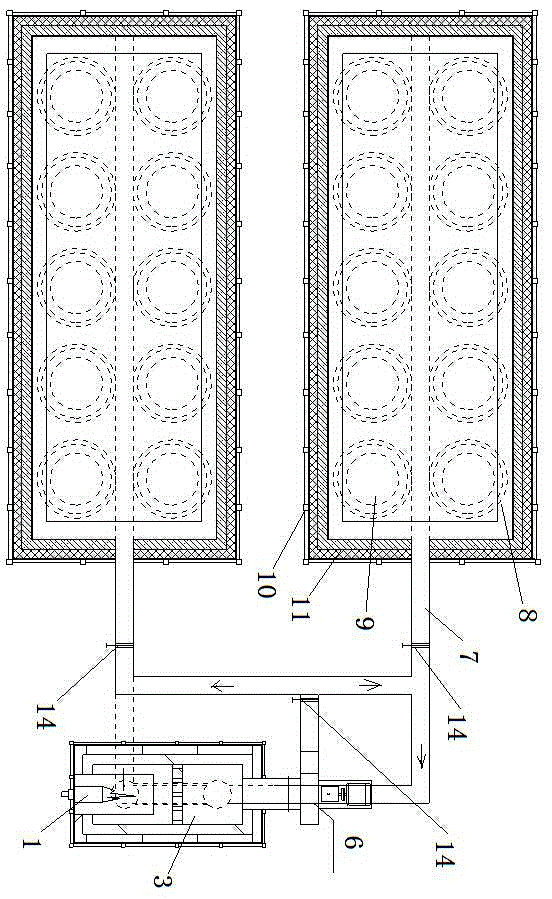

Method used

Image

Examples

Embodiment 1

[0042] 1. Ingredients: the main material is 100kg (the crushing particle size is 40 mesh); the auxiliary material is 160-300kg; the starter is 40kg; the main material is sorghum; the auxiliary material is wheat bran and rice bran; The ratio between them is 1:1~1.5; Daqu is used as starter;

[0043] 2. Mix the main ingredients and auxiliary ingredients first, then steam for 1.5-2 hours;

[0044] 3. Cool the steamed raw materials to room temperature;

[0045] 4. Add starter to the cooled raw materials and mix well;

[0046] 5. Put the raw materials added with the starter into the fermentation tank, carry out alcoholic fermentation at room temperature for 9-18 days, and then carry out acetic acid fermentation at room temperature for 9 days to ferment into mature vinegar unstrained spirits.

[0047] 6. Put the mature vinegar unstrained spirits into the storage tank (ie heat-resistant stainless steel tank) built into the baking (smoking) furnace and seal it;

[0048] 7. Start th...

Embodiment 2

[0062] Embodiment 2: The difference between this embodiment and Embodiment 1 lies in the fully automatic control of the burner, and the others are the same as Embodiment 1.

[0063] Fully automatic burner control includes manual cut-off valve, gas filter, gas pressure switch, safety valve, gas pressure regulator, valve leak detection controller, working valve, gas butterfly servo motor, air servo motor, air pressure switch, combustion head and gas butterfly valve;

[0064] The manual cut-off valve is connected to the gas filter through the coupling, the gas filter is connected to the gas pressure switch through the pipeline, the gas pressure switch is connected to the safety valve through the pipeline, the safety valve is connected to the gas pressure regulator through the pipeline, and the gas pressure regulator is connected to the valve detection through the pipeline. The leak controller and the valve leak detection controller are connected to the working solenoid valve thro...

Embodiment 3

[0079] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the electrical connection of the fully automatic control burner of this embodiment includes a control board, and pin 1 of the control board is connected to the ionization electrode;

[0080] The N pin of the valve leak detection controller is connected to the 6 pin of the air servo motor, the L1 pin of the valve leak detection controller is connected to the 3 pin of the air servo motor, and the T2 pin of the valve leak detection controller is connected to the 2 pin of the gas pressure switch;

[0081] Connect pin 2 of the control board to the connection line between pin N of the valve leak detection controller and pin 6 of the air servo motor;

[0082] The 3 pins of the control board are respectively connected to the 3 pins of the air pressure switch, the 8 pins of the air servo motor and one end of the gas servo motor; the other end of the gas servo motor is connected to the N pin of the valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com