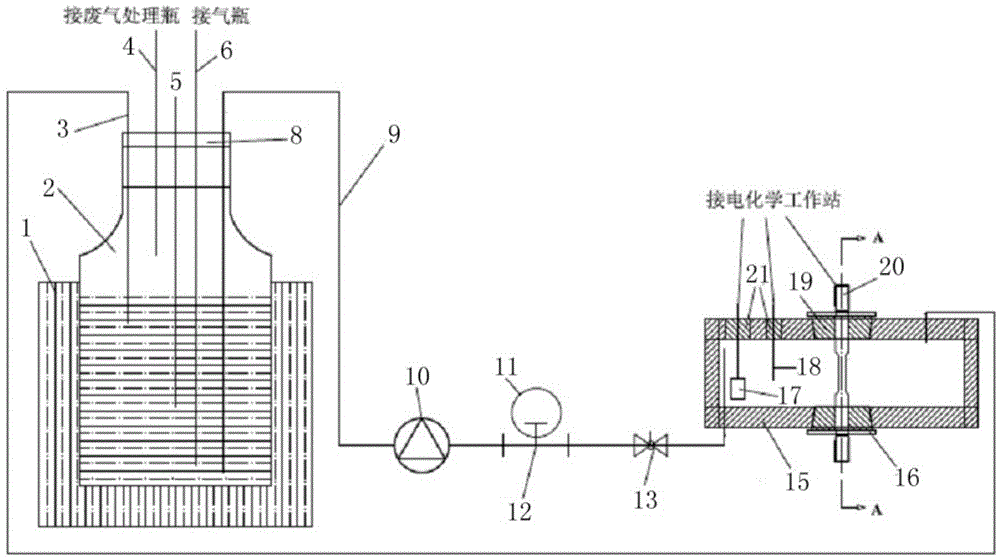

Apparatus for environment corrosion cracking test in wet hydrogen sulfide environment

An environmental corrosion and cracking test technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of easy failure of axial seals, corrosion fatigue, leakage, etc., to achieve beautiful appearance, cost saving, simplification The effect of the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

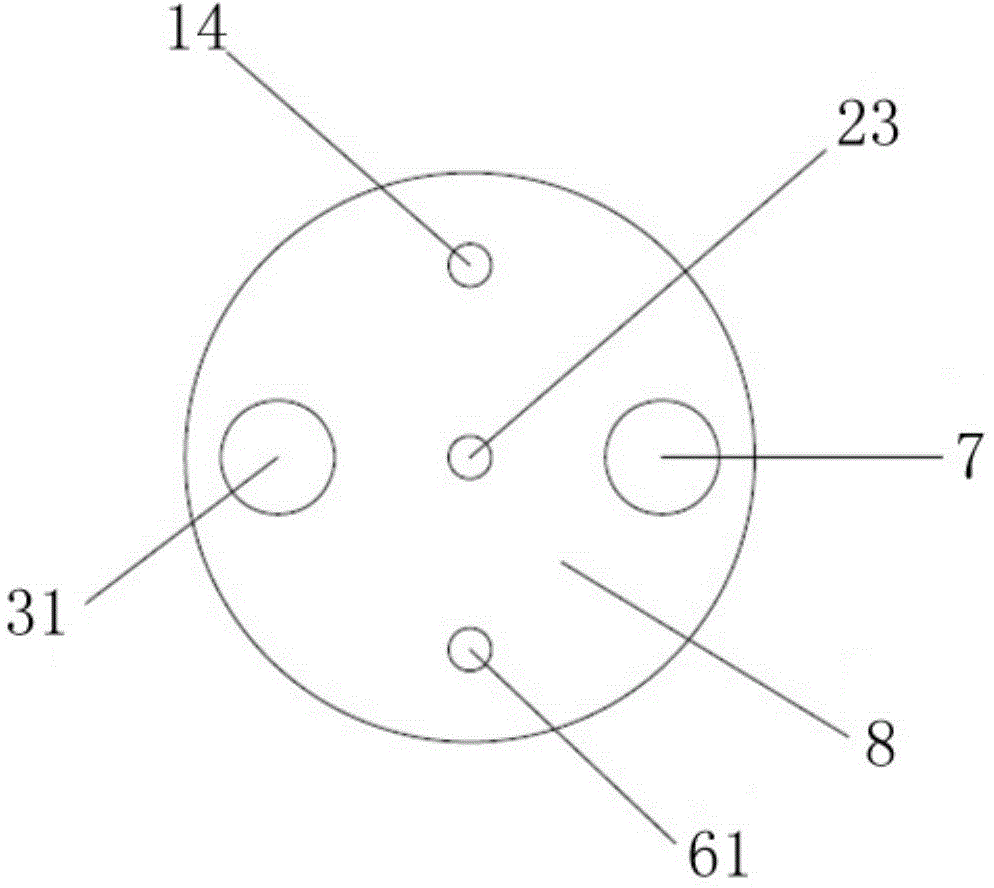

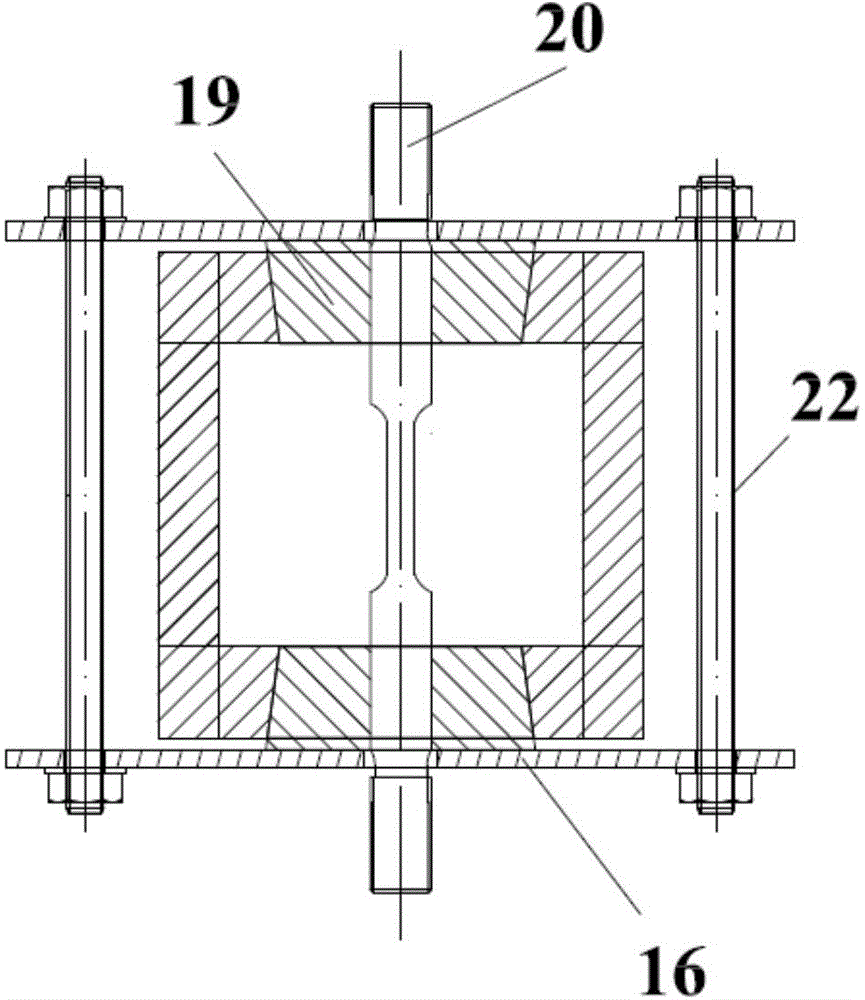

Method used

Image

Examples

Embodiment 1

[0034] In this example, after installing the corresponding sample, pour 2L of NACE A solution (5wt%NaCl+0.5wt%HAc) into the corrosion solution storage container, set the temperature of the water bath to 24°C, close the ball valve, Inject 100-200ml / min N 2 Two hours to remove the dissolved oxygen in the solution, and then fill the solution with H at a speed of 200ml / min according to the test requirements 2 S. After two hours, press and pinch the rubber ball to fill the magnetic pump with solution, open the ball valve, start the magnetic pump, check the airtightness, and start the corresponding test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com