Bilirubin electrochemical transducer and preparation method thereof

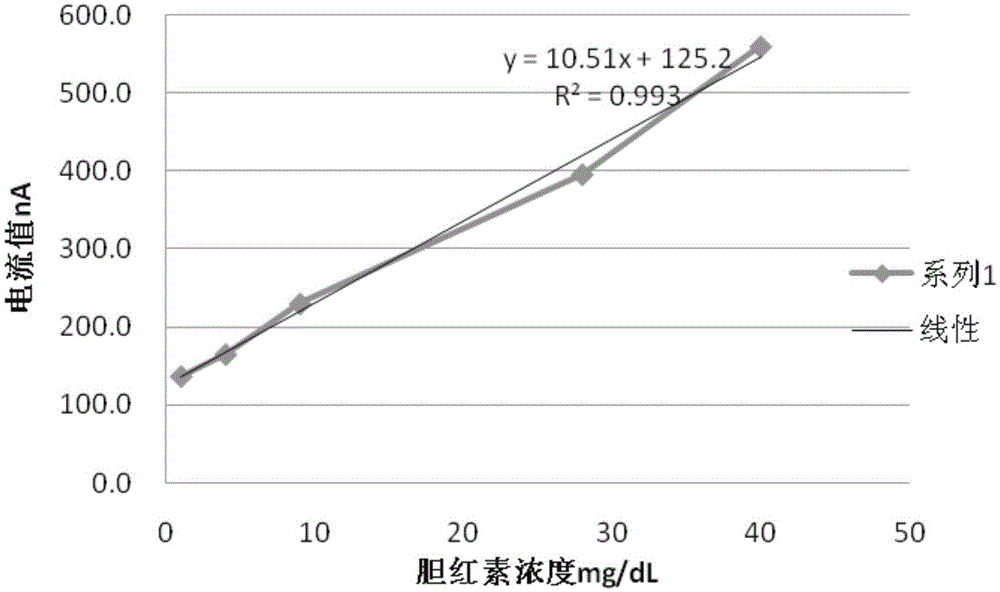

A bilirubin oxidase, electrochemical technology, applied in the field of electrochemical detection, can solve the problems of poor anti-interference ability, long reaction time, interference, etc., to achieve the effect of improving accuracy and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The preparation of embodiment 1 bilirubin electrochemical sensor

[0067] Conductive carbon paste was printed on PET using screen printing technology to make carbon electrodes.

[0068] Weigh 1g of copper sulfate, 0.01g of bilirubin oxidase, 0.5g of BYK163, 2g of carboxymethylcellulose, and 97g of pure water, and use a high-speed mixer to stir while adding, the speed is controlled at 600rpm, and the time is controlled at 15 minutes , after the enzyme solution is mixed, control the speed of the mixer at 1200rpm and stir for 3 hours to obtain the enzyme solution of the bilirubin oxidase system; use the screen printing technology to print the prepared enzyme solution on the carbon electrode, and dry it in an oven to form membrane to obtain a semi-finished bilirubin electrochemical sensor.

[0069] Weigh 0.2g of ascorbate oxidase, 0.5g of Tween-60, 2g of carboxymethyl cellulose, and 98g of pure water, and use a high-speed mixer to stir while adding, the speed is controlled...

Embodiment 2

[0073] The preparation of embodiment 2 bilirubin electrochemical sensor

[0074] Conductive carbon paste was printed on PET using screen printing technology to make carbon electrodes.

[0075] Weigh 1.5g of copper chloride, 15mg of bilirubin oxidase, 0.5g of TEGO Dispers 655, 2g of hydroxyethyl cellulose, 66g of pure water, and 30g of isopropanol, and stir while adding them using a high-speed mixer, with the speed controlled At 600rpm, the time is controlled at 15 minutes. After the enzyme solution is mixed, the mixer speed is controlled at 1200rpm and stirred for 3 hours to obtain the enzyme solution of the bilirubin oxidase system; the prepared enzyme solution is printed on carbon by screen printing technology. The electrodes are dried in an oven to form a film to obtain a semi-finished product of the bilirubin electrochemical sensor.

[0076] Weigh 0.1g of ascorbate oxidase, 0.5g of triton, 5g of hydroxyethyl cellulose, and 95g of pure water, and use a high-speed mixer to ...

Embodiment 3

[0078] The preparation of embodiment 3 bilirubin electrochemical sensor

[0079] Conductive carbon paste was printed on PET using screen printing technology to make carbon electrodes.

[0080] Weigh 1.5g of methylene blue, 15mg of bilirubin oxidase, 1g of EFKA4320, 2g of chitosan, 75g of pure water, 20g of ethanol, and use a high-speed mixer to stir while adding, the speed is controlled at 600rpm, and the time is controlled at After 15 minutes, wait for the enzyme solution to mix well, then control the speed of the mixer at 1200rpm and stir for 3 hours to obtain the enzyme solution of the bilirubin oxidase system; print the prepared enzyme solution on the carbon electrode using screen printing technology, and dry it in an oven. Dry into a film to obtain a semi-finished product of the bilirubin electrochemical sensor.

[0081] Weigh 0.3g of ascorbate oxidase, 1g of sodium lauryl sulfate, 1g of chitosan, and 98g of pure water, and use a high-speed mixer to stir while adding, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com