Sodium alginate-flaky zif-8 hybrid composite membrane and its preparation and application

A technology of sodium alginate and hybrid compounding, which is applied in the field of membrane separation, can solve the problems of selectivity decline, and achieve the effects of high membrane stability, convenient scale preparation and amplification, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, sodium alginate-flaky ZIF-8 hybrid composite film, its preparation steps are as follows:

[0023] Step 1. Add sodium alginate to deionized water, stir at 30°C for 1 hour, prepare a sodium alginate solution with a mass concentration of 32%, and set aside;

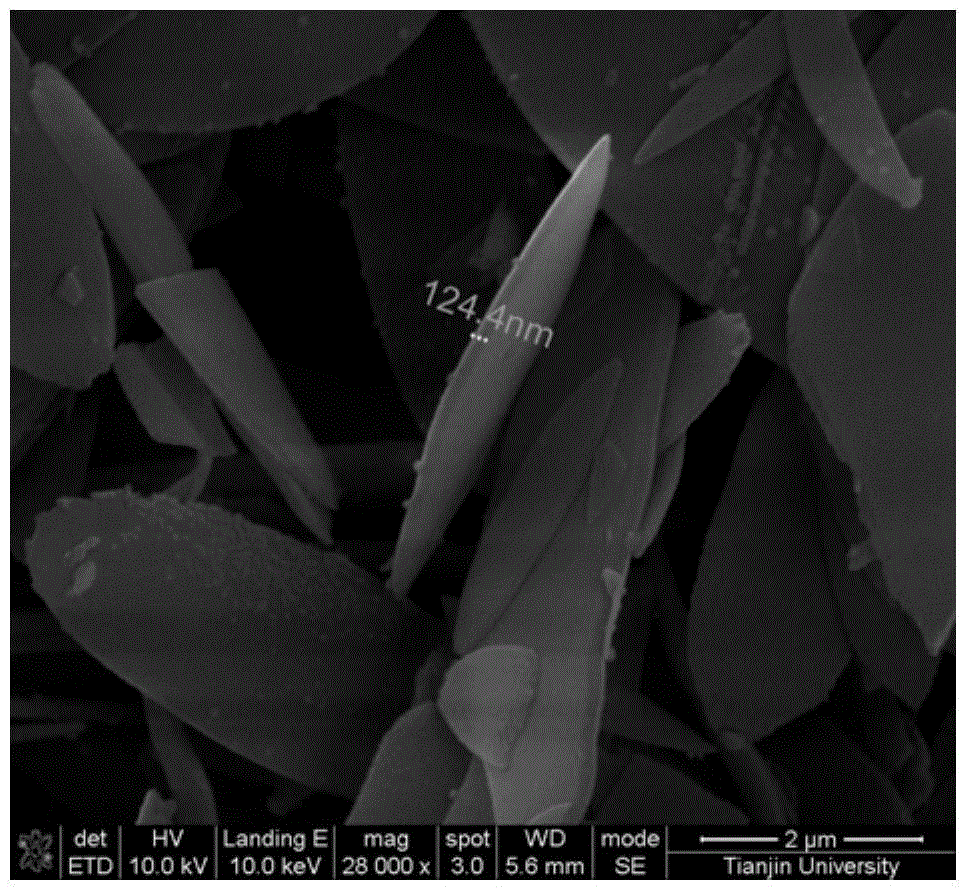

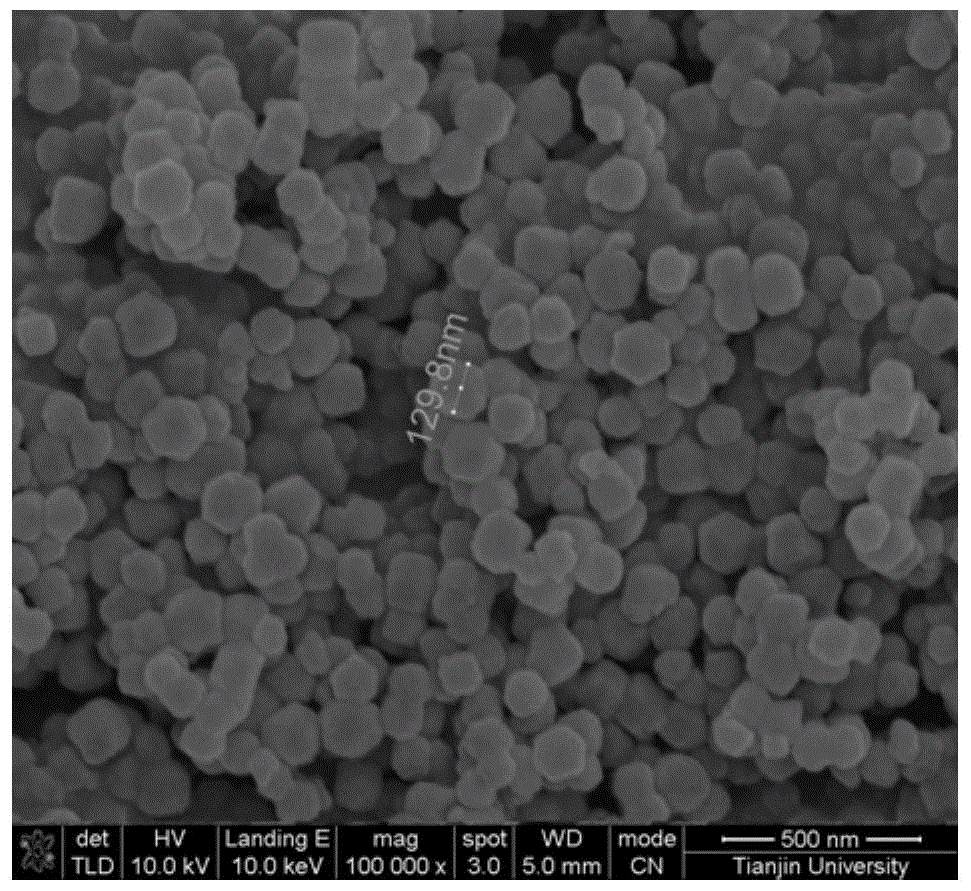

[0024] Step two, with Zn(NO 3 ) 2 and 2-methylimidazole as raw materials, the water phase is prepared to obtain sheet ZIF-8, the specific process is: Zn(NO 3 ) 2 Dissolved in deionized water to prepare Zn(NO 3 ) 2 solution, 2-methylimidazole is dissolved in deionized water to prepare a concentration of 2-methylimidazole solution of 0.4mol / L, and the Zn(NO 3 ) 2 The solution and the 2-methylimidazole solution were mixed uniformly at a volume ratio of 1:1, and magnetically stirred at 600 rpm for 4 hours at 30°C to obtain a milky white suspension; the suspension was filtered with a cellulose acetate microfiltration membrane with a pore size of 0.2 μm, The filter cake was redispersed into deionized wa...

Embodiment 2

[0029]Embodiment 2, sodium alginate-flaky ZIF-8 hybrid composite film, its preparation procedure is basically the same as embodiment 1, the only difference is, in step 3, the consumption of flake ZIF-8 is accounted for sodium alginate 2wt.% is changed to account for 4wt.% of sodium alginate; The SEM surface photo of the finally obtained sodium alginate-flaky ZIF-8 hybrid composite film is as follows figure 2 shown.

[0030] The sodium alginate-sheet ZIF-8 hybrid composite membrane prepared in Example 2 was used to test the ethanol / water separation performance. Using membrane separation equipment, the ethanol / water pervaporation separation performance test was carried out at 76°C and the mass ratio of ethanol / water in the raw material solution was 9:1, and the permeation flux was 1218g / m 2 h, the separation factor is 1840.

Embodiment 3

[0031] Embodiment 3, sodium alginate-flaky ZIF-8 hybrid composite film, its preparation procedure is basically the same as embodiment 1, the only difference is that, in step 3, the consumption of flake ZIF-8 is accounted for sodium alginate 2wt.% is changed to account for 6wt.% of sodium alginate.

[0032] The sodium alginate-sheet ZIF-8 hybrid composite membrane prepared in Example 3 was used to test the ethanol / water separation performance. Using membrane separation equipment, the ethanol / water pervaporation separation performance test was carried out at 76°C and the mass ratio of ethanol / water in the raw material solution was 9:1, and the permeation flux was 1066g / m 2 h, the separation factor is 1222.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com