Methanol-to-olefin reaction device

A methanol-to-olefins and reaction equipment technology, which is applied in coal-to-olefins and petrochemical fields, can solve problems such as lower yield and conversion rate of target products, uneven distribution of gas-solid, back-mixing of gas-solid two-phase, etc., and achieve improved contact Effect, reduce the concentration of fine powder particles, reduce the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

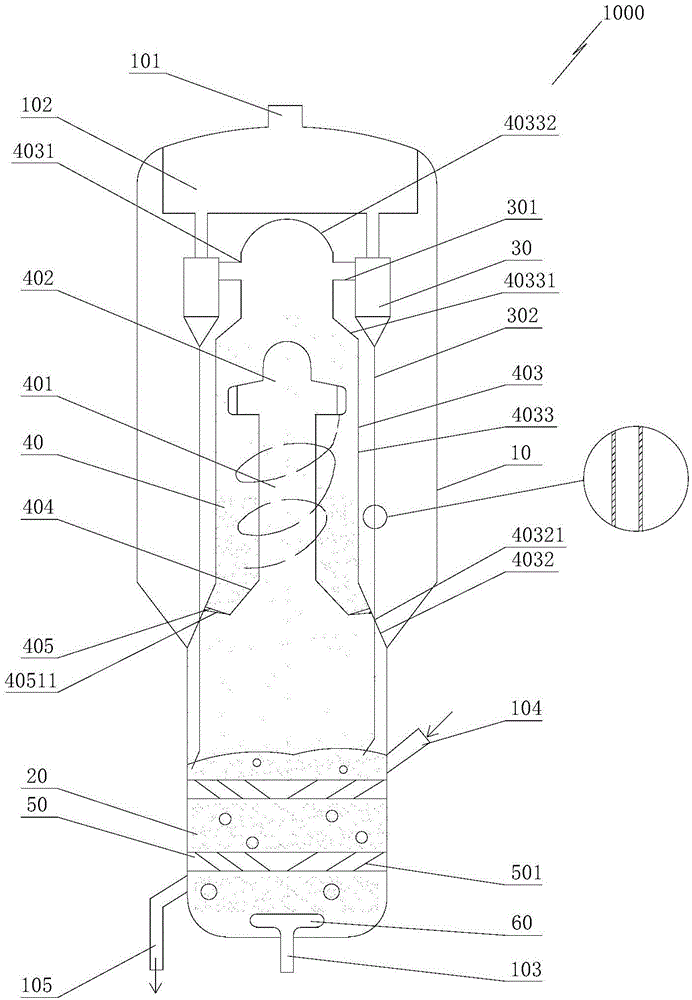

[0032] As a preferred embodiment of this embodiment, such as figure 1 As shown, the bottom of the outer cover 403 is provided with a second conical section 4032 that penetrates up and down. The diameter of the second conical section 4032 tapers upwards. The bottom of the second conical section 4032 constitutes the bottom of the gas-solid separation device 40. The second conical section The outside of the bottom of 4032 is in sealing connection with the inner wall of the housing 10, the first tapered section 404 is located inside the second tapered section 4032, and the bottom of the first tapered section 404 is connected to the inside of the second tapered section 4032 through an annular plate 405, as Figure 4 As shown, the annular plate 405 is evenly provided with a plurality of slots 4051 in the circumferential direction; the side wall of the second tapered section 4032 is provided with a first through hole 40321, and the particle output pipe 302 is sealed and enters the den...

Embodiment 2

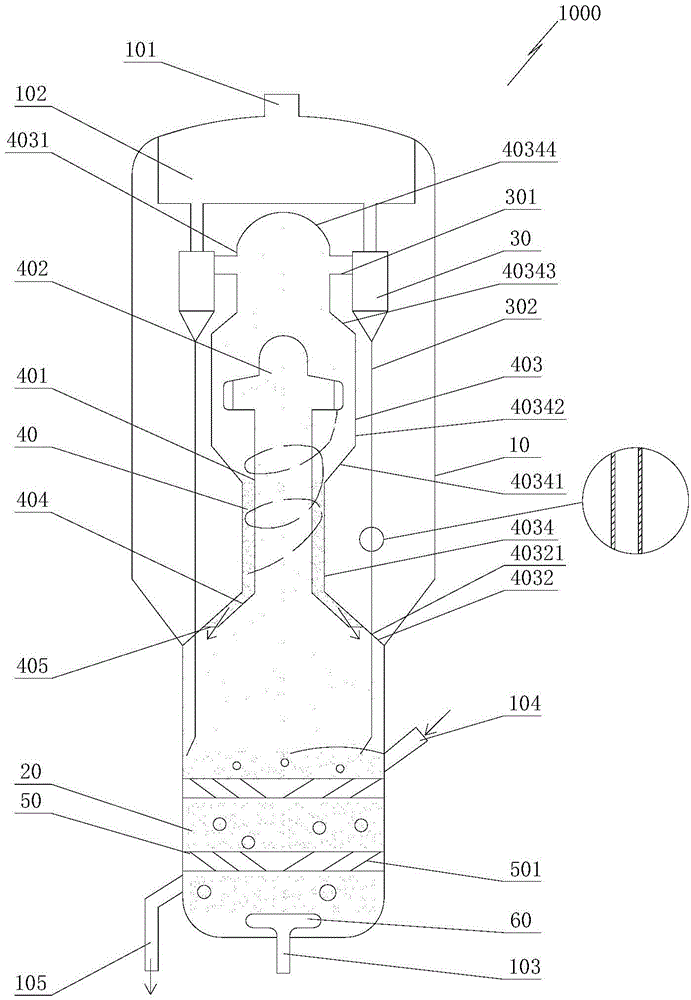

[0041] The basic principle and structure of this embodiment are the same as those of Embodiment 1, the difference lies in the structural form of the outer cover 403 and the one-way conduction way between the first conical section 404 and the dense-phase fluidized bed 20 from top to bottom.

[0042] Such as figure 2 As shown, in the second embodiment, the bottom of the outer cover 403 is provided with a second conical section 4032 that penetrates up and down. Bottom, the outside of the bottom of the second tapered section 4032 is in sealing connection with the inner wall of the housing 10, the first tapered section 404 is located inside the second tapered section 4032, and the bottom of the first tapered section 404 is connected to the second tapered section 405 through an annular plate 405. Shaped segment 4032 is connected inside, such as Figure 5 As shown, the annular plate 405 is evenly provided with a plurality of slots 4051; the side wall of the second tapered section 4...

Embodiment 3

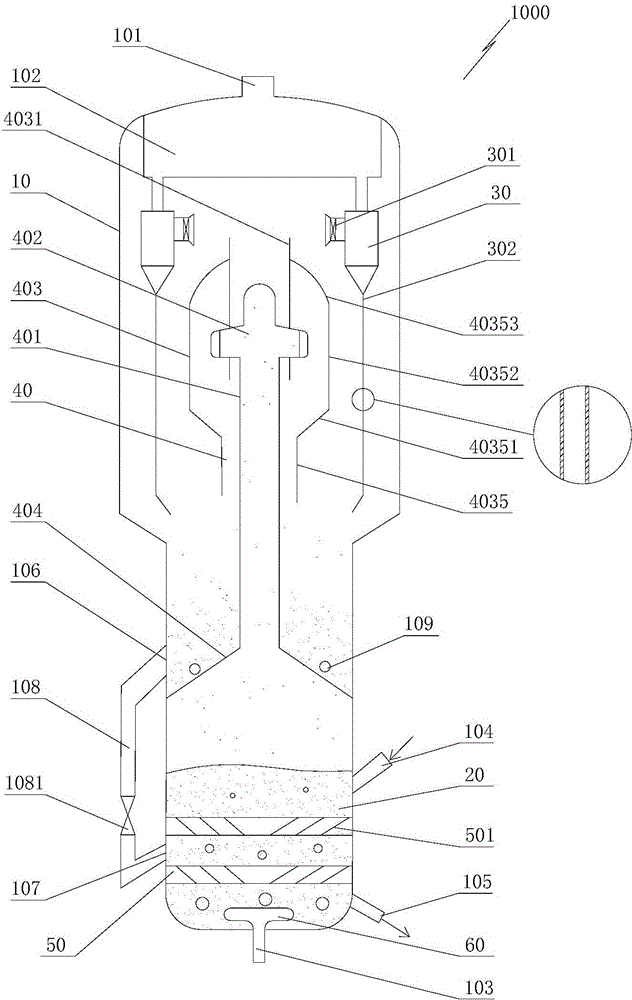

[0046] Such as image 3As shown, in the third embodiment, the bottom of the first conical section 404 constitutes the bottom of the gas-solid separation device 40, the outer side of the bottom of the first conical section 404 is in sealing connection with the inner wall of the housing 10, and the outer cover 403 includes the first conical section The fourth straight pipe 4035 arranged above 404, the quick separation device 402 is arranged above the inside of the fourth straight pipe 4035, the top of the fourth straight pipe 4035 is connected with a sixth tapered section 40351 whose diameter gradually expands upwards, and the sixth tapered section 40351 The top is connected with the fifth straight pipe 40352 , the top of the fifth straight pipe 40352 is connected with the third head 40353 , the top of the third head 40353 is provided with a first outlet 4031 , and the first outlet 4031 communicates with the first inlet pipe 301 . The outlet of the particle output pipe 302 is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com