Forming device, and forming method of gas-phase differential-method saturated materials in forming device

A technology of gas phase differentiation and material molding, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of immature production lines and no industrial production, and achieve uniformity and flatness, cleanliness, and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

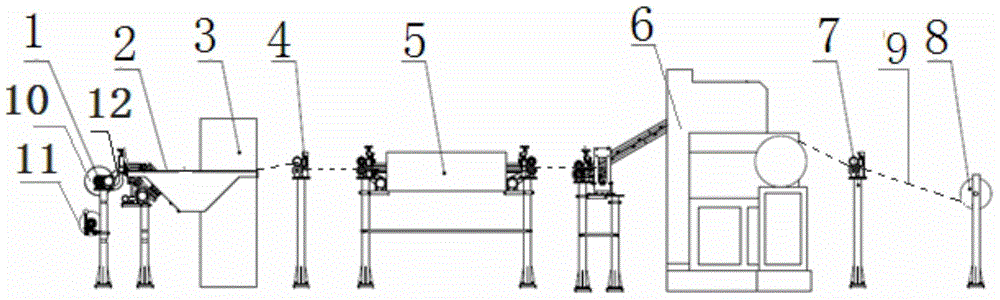

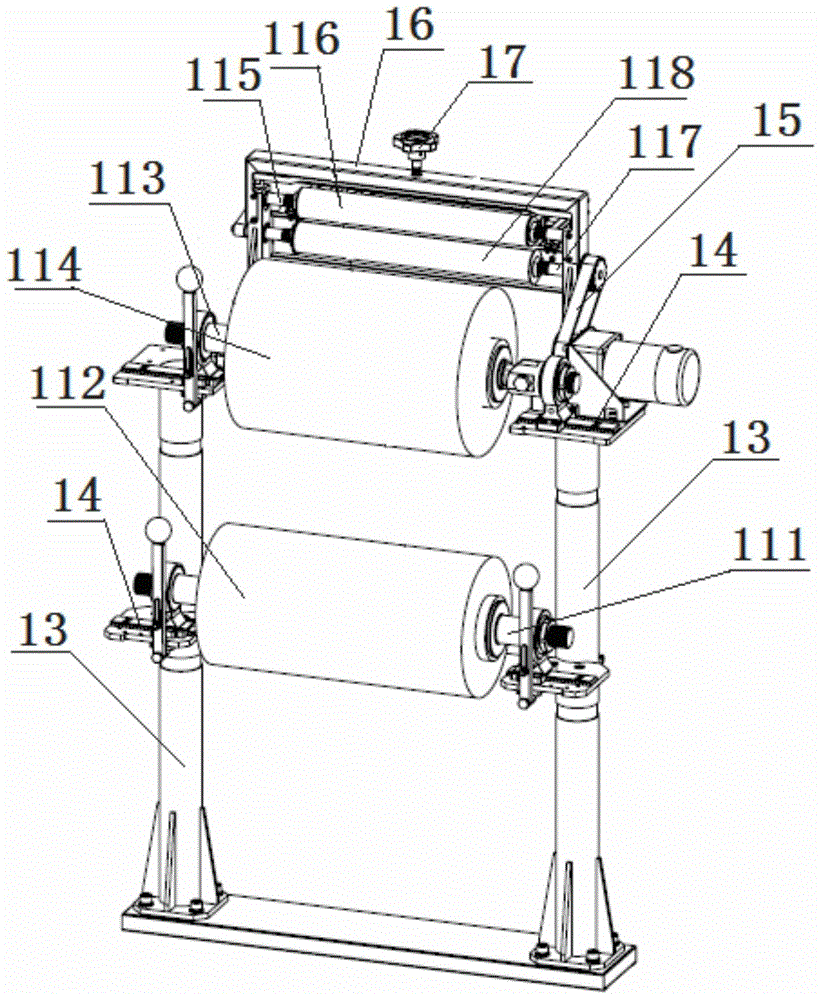

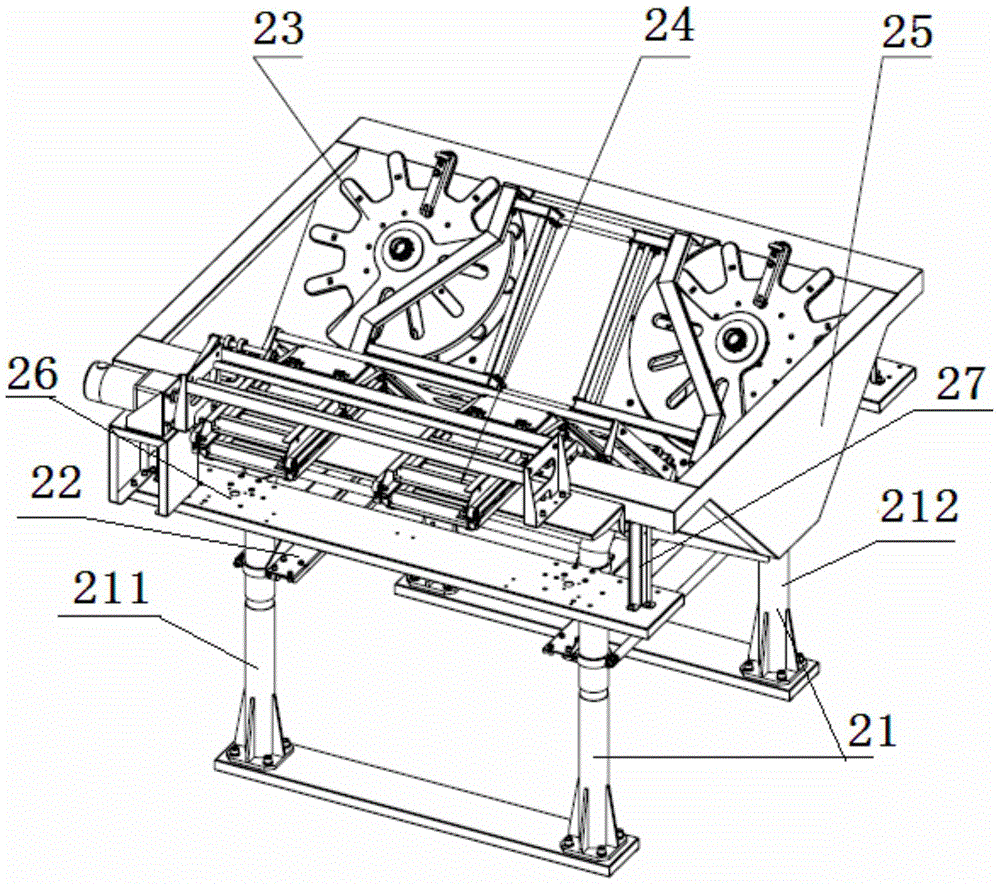

[0044] Such as Figure 1 to Figure 6 As shown, the vapor phase differential method saturated material forming device includes a discharge device 1 provided with an output mechanism 10, a stretching device 2, a heating cycle device 3, a first cutting device 4, an oven 5, a calendering device 6, and a second cutting device 7. Winding device 8, between stretching device 2 and heating cycle device 3, between heating cycle device 3 and first trimming device 4, between first trimming device 4 and oven 5, between oven 5 and calendering device 6 Between the calendering device 6 and the second cutting device 7, between the second cutting device 7 and the winding device 8, a transmission mechanism 9 is arranged, and the output devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com