A process for extracting high-purity oxidized resveratrol from mulberry

A technology for oxidizing resveratrol and mulberry, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of low product yield and quality, long production cycle, outdated technology, etc. Low, easy to operate, good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

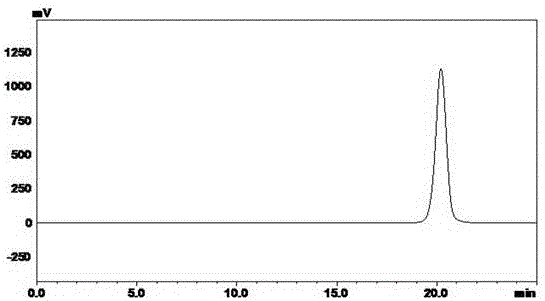

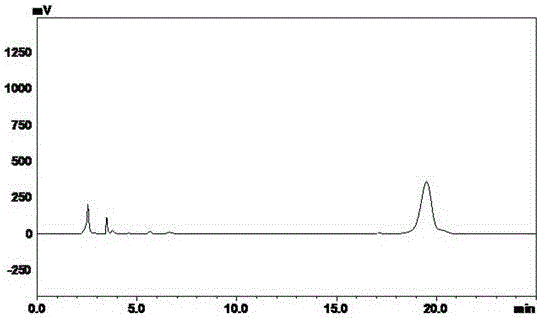

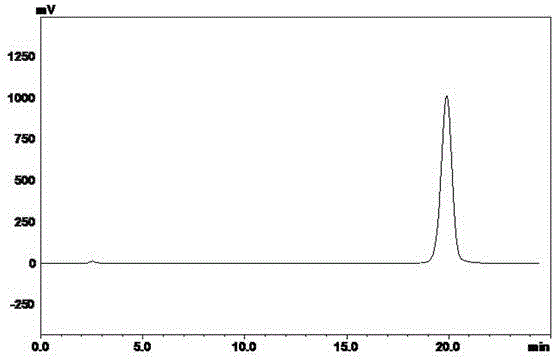

Image

Examples

Embodiment 1

[0031] A process for extracting high-purity oxidized resveratrol from mulberry trees, comprising the following steps:

[0032] (1) First crush the dried mulberry rhizomes and pass through a 10-mesh sieve;

[0033] (2) Add 60% pure ethanol solvent according to the mass volume ratio of mulberry rhizome and ethanol solution 1:8, stir and extract the crushed mulberry rhizome at 80°C, the extraction time is 2.5h, and filter to obtain the filtrate; repeat stirring Extract 4 times, combine filtrate;

[0034] (3) Concentrate the ethanol filtrate to one-tenth of the original volume, measure the solid content, control the solid content at 10%-15%, add ethyl acetate 5 times the volume of the concentrated solution to extract the oxidized resveratrol, and fully stir After that, stand still until the layers are separated, and the ethyl acetate layer is separated; the ethyl acetate extraction is repeated 3 times, and the ethyl acetate solution is combined;

[0035] (4) Ethyl acetate is eas...

Embodiment 2

[0042] A process for extracting high-purity oxidized resveratrol from mulberry trees, comprising the following steps:

[0043] (1) First crush the dried mulberry rhizomes and pass through a 10-mesh sieve;

[0044] (2) Add 70% pure ethanol solvent according to the mass volume ratio of mulberry rhizome and ethanol solution 1:7, stir and extract the crushed mulberry rhizome at 70°C, the extraction time is 2h, and filter to obtain the filtrate; repeat the stirring and extraction 3 times, combined filtrate;

[0045] (3) Concentrate the ethanol filtrate to one-tenth of the original volume, measure the solid content, control the solid content at 10%-15%, add 4 times ethyl acetate to extract the oxidized resveratrol, stir well, and stand still until Separate the layers and separate the ethyl acetate layer; repeat the ethyl acetate extraction 3 times, and combine the ethyl acetate solution;

[0046] (4) Ethyl acetate is easily concentrated to a paste, and 80% pure ethanol is added ac...

Embodiment 3

[0052] A process for extracting high-purity oxidized resveratrol from mulberry trees, comprising the following steps:

[0053] (1) First crush the dried mulberry rhizomes and pass through a 10-mesh sieve;

[0054] (2) Add 80% pure ethanol solvent according to the mass volume ratio of mulberry rhizome and ethanol solution 1:7, stir and extract the crushed mulberry rhizome at 60°C, the extraction time is 1.5h, and filter to obtain the filtrate; repeat stirring Extract 3 times, combine filtrate;

[0055] (3) Concentrate the ethanol filtrate to one-tenth of the original volume, measure the solid content, control the solid content at 10%-15%, add 3 times ethyl acetate to extract the oxidized resveratrol, stir well, and stand still until Separate the layers and separate the ethyl acetate layer; repeat the ethyl acetate extraction twice, and combine the ethyl acetate solution;

[0056] (4) Ethyl acetate is easily concentrated into a paste, and 85% pure ethanol is added according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com